car door glass rubber seal exporter

The Importance of Car Door Glass Rubber Seals in the Automotive Industry

In the competitive landscape of the automotive industry, every component plays a crucial role in enhancing the overall performance and safety of vehicles. Among these components, car door glass rubber seals may seem small and unassuming, but their significance cannot be overstated. As an essential part of a vehicle’s design, these seals ensure that windows fit securely, preventing water, dust, and noise from entering the cabin. This article explores the importance of car door glass rubber seals and their impact on vehicle quality, comfort, and the growing demand for exports in this sector.

Functionality and Benefits

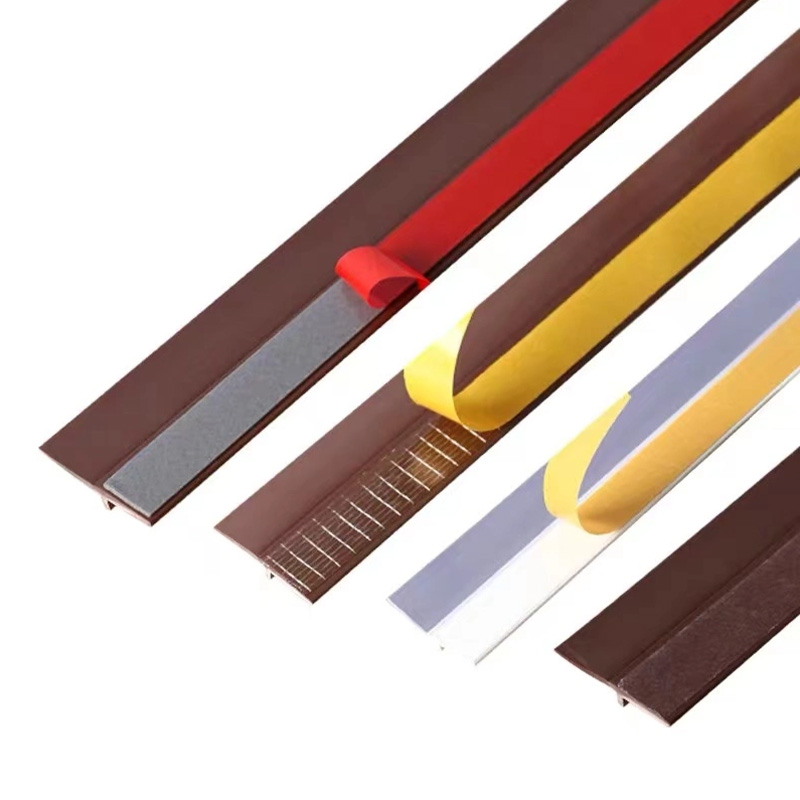

Car door glass rubber seals, often referred to as weatherstrips, serve as a barrier between the vehicle’s exterior and interior. They are designed to achieve several key functionalities. First and foremost, they provide protection against the elements. During rain or snow, rubber seals prevent water from leaking into the car, which is critical for maintaining the integrity of the interior and avoiding costly repairs caused by water damage. Similarly, these seals are vital in blocking out dust, dirt, and other debris that can find their way into the vehicle.

Moreover, car door glass rubber seals play a significant role in acoustic insulation. High-quality seals dampen external noise, providing passengers with a quieter and more enjoyable driving experience. This reduction in noise not only enhances comfort but also contributes to a more premium feel of the vehicle, which is a crucial factor for manufacturers aiming to attract discerning customers.

Quality and Durability

car door glass rubber seal exporter

The materials used in manufacturing car door glass rubber seals are pivotal. High-grade rubber compounds are commonly employed to ensure that the seals are not only flexible and durable but also resistant to temperature fluctuations, UV rays, and the wear and tear of daily use. Exporters focusing on this component are increasingly adopting advanced manufacturing techniques and quality standards to produce seals that meet or exceed industry expectations.

Many manufacturers are now using synthetic rubber blends to enhance durability and performance. These modern materials can extend the lifespan of the seals, reducing the need for replacements and aiding in overall vehicle maintenance. With the increasing focus on sustainability, some companies are also exploring eco-friendly materials and production methods, which is a notable trend in the automotive supply chain.

Export Opportunities and Market Trends

The global automotive market continues to grow, fueled by rising consumer demand for new vehicles and technological advancements in automotive design. As a result, the demand for car door glass rubber seals is on the rise, creating lucrative export opportunities for manufacturers specializing in this niche.

Asia-Pacific, particularly China and India, has emerged as a significant hub for automotive manufacturing, and consequently, for the production of rubber seals. These countries are not only meeting domestic demand but are also exporting to markets in North America, Europe, and beyond. Exporters in this sector must stay ahead by maintaining high standards of quality, efficiency, and compliance with international regulations.

In conclusion, while car door glass rubber seals may not be the most glamorous aspect of automotive design, their importance is undeniable. They contribute to the functionality, safety, and comfort of vehicles, while also representing significant economic opportunities through exports. As the automotive industry continues to evolve, the demand for high-quality rubber seals will undoubtedly grow, presenting a bright future for manufacturers and exporters alike. Emphasizing innovation and quality will be key to remaining competitive in this essential sector of the automotive supply chain.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025