Factories Producing Rubber Seals for Car Door and Window Applications

The Importance of Quality Rubber Seals in Car Door Windows

In the automotive industry, every component plays a crucial role in ensuring a vehicle's functionality and safety. Among these components, rubber seals for car door windows are essential yet often overlooked parts that significantly contribute to overall performance and user satisfaction.

What Are Rubber Seals?

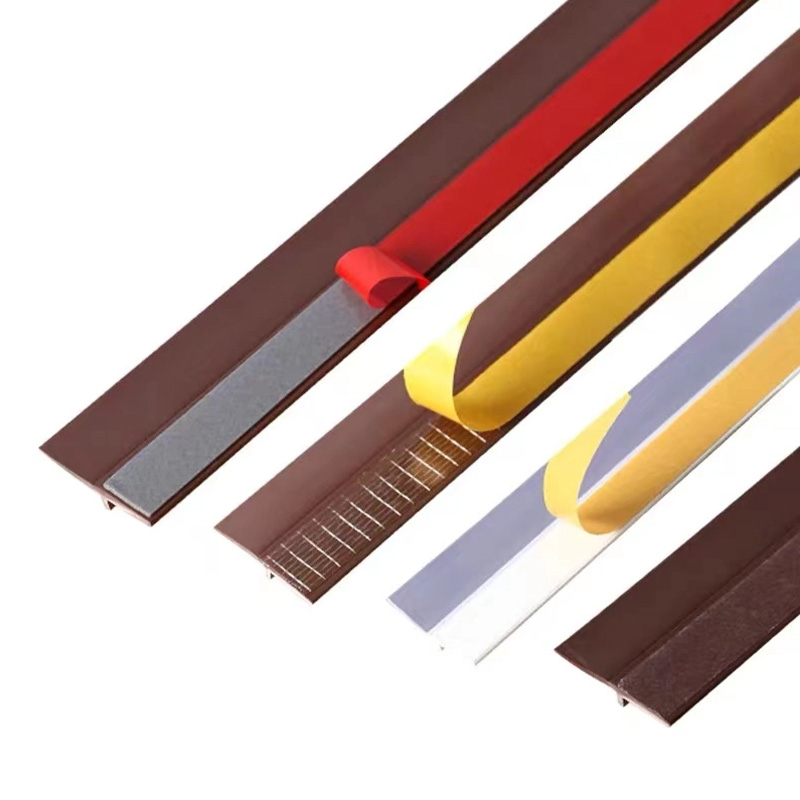

Rubber seals, specifically for car door windows, are designed to create a tight barrier between the window glass and the vehicle body. Made from high-quality rubber compounds, these seals serve several key purposes. They help to prevent water, dust, and wind from entering the vehicle, thereby providing a more comfortable driving experience. Moreover, they ensure that the window operates smoothly, minimizing rattling and enhancing durability.

The Manufacturing Process

The production of rubber seals involves several intricate steps requiring precision and quality control. This process generally begins with the selection of raw materials. High-quality rubber, often combined with additives to enhance durability and elasticity, is used to create seals that can withstand various environmental conditions, including extreme temperatures and UV exposure.

Once the materials are chosen, the manufacturing process includes molding and curing. The rubber is shaped into the desired form using molds, followed by a curing process that solidifies the rubber and gives it the necessary strength and flexibility. After the curing, the seals undergo rigorous quality testing to ensure they meet industry standards before being distributed to automotive manufacturers.

Factors Affecting Quality

car door windows rubber seal factories

Several factors impact the quality of rubber seals. The choice of material is paramount; inferior materials can lead to seals that degrade quickly or fail to provide adequate protection. Climate conditions during manufacturing, such as humidity and temperature, also play a vital role in the final product's quality. Efficient manufacturing processes and stringent quality control measures ensure that only the best products make it to the market.

Benefits of High-Quality Rubber Seals

Investing in high-quality rubber seals offers numerous benefits. Firstly, they provide superior noise reduction, creating a tranquil cabin environment. Effective seals can significantly decrease wind and road noise, enhancing the overall driving experience. Secondly, these seals ensure better insulation against external weather elements, contributing to climate control within the vehicle. Subsequently, this can lead to improved fuel efficiency, as heating or cooling systems do not need to work harder to maintain desired temperatures.

Additionally, reliable rubber seals can improve the longevity of the vehicle's interior by protecting it from moisture and dirt intrusion. This protection helps prevent mold growth and deterioration of materials, ensuring that the car maintains its aesthetic appeal and resale value.

The Role of Factories

Manufacturers play a pivotal role in the automotive supply chain. Factories specializing in rubber seals are tasked with continuous innovation to improve their products. They are constantly researching ways to enhance the materials used, improve production efficiency, and reduce waste. Collaboration between automotive manufacturers and seal manufacturers is crucial for developing seals that meet the specific requirements of various car models and technologies.

Conclusion

In conclusion, rubber seals for car door windows are significant components that ensure vehicles are comfortable, safe, and efficient. The quality of these seals can greatly influence the overall driving experience, from noise reduction to insulation. As the automotive industry continues to evolve, the importance of investing in high-quality rubber seals becomes increasingly clear. As consumers demand better performance and safety standards, manufacturers must prioritize the production of top-tier rubber seals, ensuring that they meet the ever-changing needs of the automotive market.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025