Cathode Calendar Production Solutions from Leading Industry Manufacturers Worldwide

The Importance of Cathode Calendar Manufacturers in Modern Industries

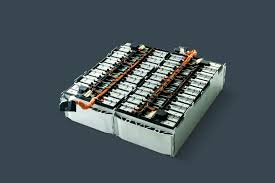

In the realm of advanced manufacturing, cathode calendar manufacturers play a pivotal role, particularly in industries that require high-precision products. Cathode calendars are essential tools used primarily in the production and processing of electrodes in various applications, including batteries, fuel cells, and other electronic components. This article delves into the importance of cathode calendar manufacturers and their impact on modern industrial practices.

Understanding Cathode Calendars

At its core, a cathode calendar is a machine designed to compress and form electrode materials into specified thickness and density. The process involves rolling a mixture of active materials, conductive additives, and binders between two rollers. The final product must meet stringent specifications regarding uniformity, thickness, and mechanical properties to ensure optimal performance in its intended application, such as lithium-ion batteries.

The precise control offered by these machines allows manufacturers to produce electrodes that can withstand multiple charge and discharge cycles while maintaining high energy density and capacity. As the demand for more efficient energy storage solutions grows, so too does the reliance on advanced cathode calendar technology.

Key Features of Cathode Calendar Manufacturers

Cathode calendar manufacturers must focus on several critical features to produce high-quality machinery. Firstly, precision engineering is essential. The alignment and smooth operation of the rollers are crucial to achieving the desired thickness and density. Manufacturers often utilize advanced computer numerical control (CNC) technology to ensure each component meets specification tolerances.

Another important aspect is the material used in production. High-quality materials that withstand wear and tear, as well as potential chemical reactions with electrode materials, are critical for longevity and performance. Many manufacturers invest in R&D to identify innovative materials that enhance the durability of their equipment.

Moreover, automation and integration with smart technologies have become increasingly important in the manufacturing landscape. Modern cathode calendars can be equipped with sensors and IoT technologies, allowing for real-time monitoring of the rolling process. This not only improves efficiency but also helps in maintaining quality control, ensuring that the final products consistently meet industry standards.

cathode calender manufacturer

The Growing Demand for Cathode Calendars

The global push towards sustainable energy solutions has significantly increased the demand for cathode calendar manufacturers. With the rise of electric vehicles (EVs) and renewable energy sources, the need for efficient battery manufacturing has never been more crucial. Cathode calendars are at the heart of this process, making them indispensable in the production of high-quality electrodes.

As industries evolve, cathode calendar manufacturers need to adapt continuously. This includes investing in research to optimize their production processes, enhancing the efficiency of their machines, and exploring new frontiers in electrode materials. Collaboration with research institutions and technology companies is also becoming vital to stay ahead in this competitive market.

Challenges Faced by Cathode Calendar Manufacturers

Despite their significance, cathode calendar manufacturers face several challenges. The rapid pace of technological advancement means that manufacturers must continually update their machinery and production techniques to keep up with industry standards. Moreover, sourcing high-quality raw materials and components can pose logistical challenges, particularly in a global supply chain subject to fluctuations.

Another concern is the environmental impact of manufacturing processes. As industries strive for sustainability, cathode calendar manufacturers are under pressure to implement eco-friendly practices in their production lines, reducing waste and energy consumption.

Conclusion

In summary, cathode calendar manufacturers are crucial players in the modern industrial landscape, enabling the production of high-performance electrodes for a variety of applications. Their focus on precision engineering, innovative materials, and advanced technologies positions them as key contributors to the sustainable energy movement. While they face challenges related to technological advancements and environmental sustainability, continued investment in R&D and collaboration can help ensure their relevance and success in the future. As the demand for efficient energy storage solutions grows, so will the importance of cathode calendar manufacturers in driving innovation and performance in this dynamic industry.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025