cathode slitting machine manufacturer

The Rise of Cathode Slitting Machine Manufacturers Innovating the Battery Industry

In recent years, the demand for lithium-ion batteries has soared, driven mainly by the explosive growth of electric vehicles (EVs), renewable energy solutions, and portable electronics. As this market continues to expand, the importance of efficient and precise manufacturing processes becomes paramount. One crucial piece of equipment in battery production is the cathode slitting machine. This article explores the significance of cathode slitting machines, the role of their manufacturers, and the latest innovations that are shaping the industry.

What is a Cathode Slitting Machine?

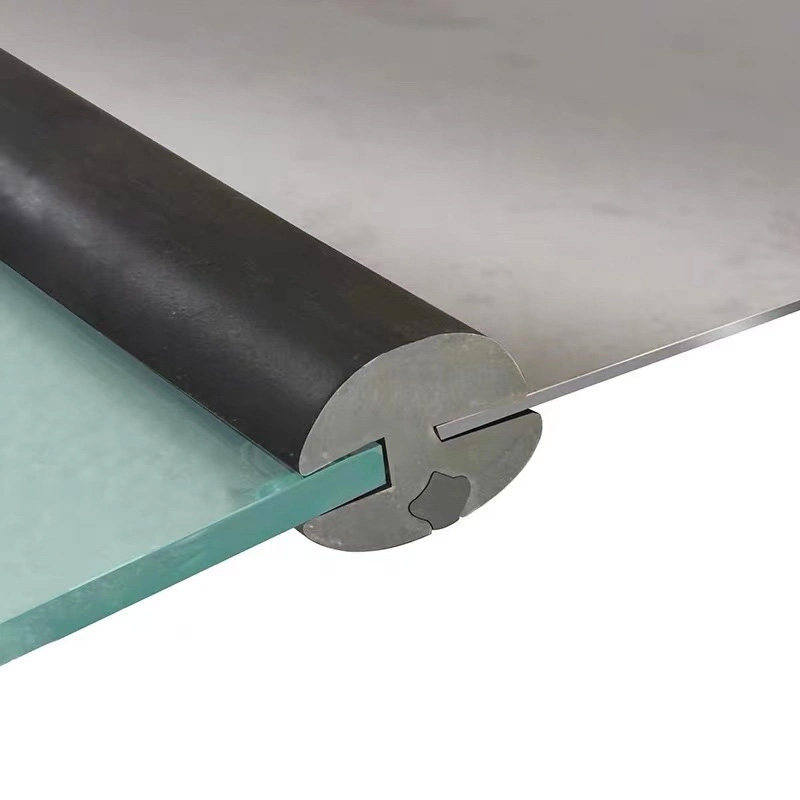

A cathode slitting machine is a specialized piece of equipment used in the production of lithium-ion battery electrodes. These machines are designed to cut cathode materials into precise sizes and shapes necessary for assembling battery cells. The quality of the cut and the uniformity of the materials are critical for ensuring high performance and longevity of the batteries. The slitting process typically involves unwinding large rolls of cathode material, slitting them to required widths, and then rewinding them for further processing.

Importance of Cathode Slitting in Battery Production

The cathode is a vital component in lithium-ion batteries, as it determines the energy density, charge capacity, and overall performance of the battery. Ensuring that cathode materials are cut with precision is essential for minimizing waste and maximizing efficiency during the manufacturing process. Any inconsistencies in the slitting can lead to defects in the battery, which may jeopardize performance and safety.

The Role of Manufacturers

Cathode slitting machine manufacturers are at the forefront of battery technology. With the increasing demand for batteries, these manufacturers strive to offer machines that enhance productivity, reduce costs, and improve output quality. Advanced manufacturing technologies, such as automation and precision engineering, have enabled these manufacturers to produce machines that meet the rigorous demands of battery production.

Leading manufacturers are focusing on developing machines that are not only fast and reliable but also easy to operate and maintain. Features such as user-friendly interfaces, real-time monitoring of the slitting process, and advanced safety mechanisms are becoming standard. Additionally, manufacturers are investing in research and development to innovate and introduce new technologies into their machines, ensuring they stay competitive in a rapidly evolving market.

cathode slitting machine manufacturer

Innovations Transforming the Slitting Process

Recent advancements in technology are revolutionizing the cathode slitting process. Here are a few notable innovations

1. High Precision Cutting Technology Modern slitting machines are equipped with advanced cutting mechanisms that enable high precision and clean cuts. This reduces burr formation and improves the quality of the cathode material.

2. Automation Automation has been a game-changer in battery manufacturing. Advanced cathode slitting machines now feature robotic arms and automated feeders that streamline the slitting process, thereby increasing efficiency and reducing human error.

3. Real-Time Monitoring Systems Many new machines come with integrated monitoring systems that track the slitting process in real-time. This allows manufacturers to adjust parameters on the fly, ensuring consistent quality and minimizing downtime.

4. Energy Efficiency As sustainability becomes a key focus in manufacturing, cathode slitting machine manufacturers are developing energy-efficient models. These machines consume less power and produce less waste, aligning with global trends towards greener manufacturing practices.

Conclusion

The demand for high-quality lithium-ion batteries is set to continue rising, and cathode slitting machine manufacturers are poised to play a crucial role in meeting this demand. By investing in innovative technologies and improving the efficiency and precision of the slitting process, these manufacturers are not only enhancing production capabilities but also contributing to the broader goals of sustainability and performance in the battery industry. As the landscape of battery production continues to evolve, the importance of reliable and cutting-edge cathode slitting machines will only grow, driving further advancements in this dynamic field.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025