China's Automotive Industry Innovations in Rubber Seal Manufacturing and Applications

The Importance of Vehicle Rubber Seals in China’s Automotive Industry

As the automotive industry in China continues to flourish, one component that plays a vital role in vehicle performance and longevity is rubber seals. These seals are common yet essential elements in various automotive applications, ranging from windows and doors to the engine and transmission systems. In this article, we will explore the significance of vehicle rubber seals, their types, manufacturing processes, and the market dynamics in China.

Understanding Vehicle Rubber Seals

Rubber seals are designed to prevent the ingress of water, dust, and other environmental elements into the vehicle’s interior and critical components. They also serve as noise and vibration dampeners, enhancing the overall comfort of passengers. The importance of rubber seals becomes apparent when considering their functionality they contribute to safety, performance, and the aesthetic appeal of the vehicle.

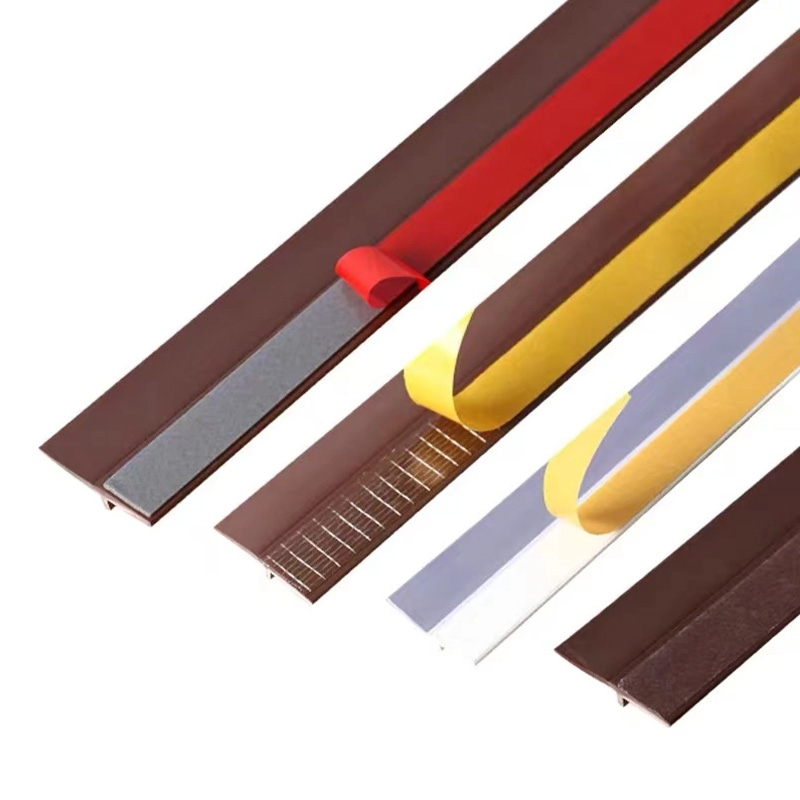

There are several types of seals used in vehicles, including door seals, window seals, trunk seals, and grommets. Each type is specifically designed to meet the unique demands of its application. For example, door seals must maintain their integrity against repeated opening and closing, while window seals must endure exposure to UV light and varying weather conditions.

Manufacturing Process of Vehicle Rubber Seals

The manufacturing of rubber seals involves several key steps, starting from the selection of raw materials to the final inspection of the finished product. The most commonly used materials include EPDM (ethylene propylene diene monomer), CR (chloroprene rubber), and NBR (nitrile rubber), each offering different properties suitable for specific applications.

1. Material Preparation The first step involves preparing the rubber compound by mixing raw rubber with additives such as carbon black, accelerators, and oils. This mixture is crucial for determining the physical properties of the final product.

2. Molding Once the compound is ready, it is placed into molds that shape the seals according to design specifications. Common techniques used include compression molding and injection molding, which allow for high precision and consistent quality.

3. Curing After molding, the rubber seals undergo a curing process, usually in a hot press. Curing solidifies the rubber, giving it strength and flexibility while ensuring durability against wear and environmental factors.

china vehicle rubber seals

4. Quality Control Finally, each batch of rubber seals is subjected to rigorous testing for quality assurance. This includes checks for tensile strength, elongation, and compression set to ensure that the seals will perform effectively in their intended applications.

The Market Dynamics in China

The vehicle rubber seal market in China is experiencing significant growth, propelled by the booming automotive sector. With the country being one of the largest automobile manufacturers in the world, the demand for high-quality rubber seals is surging alongside vehicle production.

Several factors contribute to this growth

- Rising Vehicle Production As domestic and international automakers ramp up production to meet consumer demands, the need for reliable rubber seals has increased substantially.

- Technological Advancements Innovations in materials science have led to the development of advanced rubber compounds that offer improved performance characteristics, such as resistance to extreme temperatures and enhanced durability.

- Focus on Quality and Compliance Chinese manufacturers are increasingly recognizing the importance of adhering to international quality standards. This focus ensures that rubber seals not only meet local requirements but are also competitive in global markets.

- Environmental Concerns With growing awareness of environmental issues, there is a trend towards the development of eco-friendly rubber materials. Manufacturers are investing in research to create biodegradable or recyclable options for vehicle seals.

Conclusion

In conclusion, vehicle rubber seals are a crucial element in the automotive industry, particularly in China, where the demand for automobiles is soaring. Their ability to enhance vehicle performance, safety, and comfort cannot be overstated. As the industry evolves, ongoing advancements in materials and manufacturing processes will continue to drive innovation, ensuring that rubber seals meet the ever-increasing expectations of consumers and manufacturers alike. The future of vehicle rubber seals in China looks promising, with ample opportunities for growth and development in this vital sector.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025