Custom Rubber Seals for Roller Doors Optimizing Performance and Durability in Manufacturing Facilities

Rubber Seal for Roller Door Factory Ensuring Quality and Efficiency

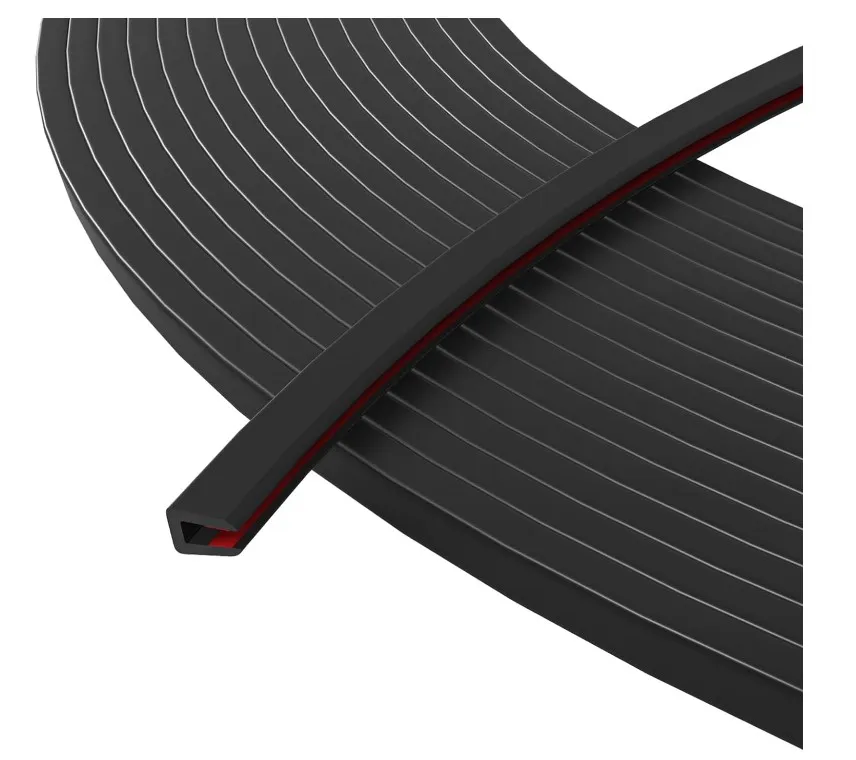

In the modern manufacturing landscape, the role of specialized components in enhancing product functionality cannot be overstated. One such critical component is the rubber seal used in roller doors. These seals not only provide an essential barrier against environmental factors but also play a significant role in the overall efficiency and security of roller doors. For factories that specialize in roller door production, investing in high-quality rubber seals is paramount.

Understanding Rubber Seals

Rubber seals act as protective barriers that prevent dust, water, insects, and other unwanted elements from infiltrating the space behind the roller doors. These seals are typically made from materials such as EPDM (Ethylene Propylene Diene Monomer), neoprene, and silicone, which are known for their durability and resistance to weathering. The diversity of rubber formulations allows manufacturers to tailor the seals for specific applications, ensuring the best fit for their roller doors.

Importance of Quality

Using high-quality rubber seals in roller doors brings several benefits. Firstly, it enhances the seal's longevity, reducing the frequency of replacements and maintenance. Cost-cutting becomes evident as the lifespan of durable seals minimizes the need for ongoing repairs and associated labor costs. Secondly, high-quality seals provide better insulation and protection from weather elements, thereby improving energy efficiency and maintaining optimal internal conditions.

A factory that produces roller doors must prioritize the quality of the rubber seals it uses to maintain a competitive edge. By sourcing seals from reputable suppliers or developing in-house production capabilities, factories can ensure that their products meet stringent industry standards.

rubber seal for roller door factory

The Manufacturing Process

The manufacturing of rubber seals involves several critical steps, from material selection to curing. Factories often begin with a thorough analysis of their requirements, considering factors such as seal size, shape, and the environmental conditions to which the roller doors will be exposed. Once the specifications are defined, the appropriate rubber formulation is selected.

The blending process is crucial, involving the mixing of raw rubber with additives, such as vulcanizing agents, to enhance the seal's properties. After producing the rubber compound, the material is shaped into seals using molds. Curing or vulcanization then follows, which involves heating the rubber to create cross-links between the polymer chains, resulting in a more durable and resilient product.

Testing and Quality Control

Before the seals are utilized in roller doors, rigorous testing is essential. Factories must implement quality control protocols to ensure that the rubber seals meet performance specifications. Tests often include examining the seals for flexibility, compression set, and resistance to weathering and chemicals. By maintaining high standards in testing, a factory can significantly reduce the risk of product failures, enhancing customer satisfaction and trust.

Conclusion

In conclusion, the critical role of rubber seals in roller doors cannot be overlooked in a factory setting. These components not only enhance the functionality of roller doors but also contribute to the overall efficiency and longevity of the products. By prioritizing quality, investing in advanced manufacturing processes, and adhering to strict testing protocols, roller door factories can ensure that they deliver reliable and high-performing products to their customers. As the demand for efficient and durable roller doors continues to grow, the significance of quality rubber seals will only increase, underpinning the need for manufacturers to adapt and evolve in this competitive landscape.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025