door rubber side seal factories

The Importance of Door Rubber Side Seals A Guide to Factories and Their Products

In an age of increased focus on energy efficiency and noise reduction, the often-overlooked components of our homes and vehicles play vital roles in ensuring comfort and functionality. One such component is the door rubber side seal. These seals are essential for maintaining insulation and eliminating drafts, ensuring that your energy costs remain manageable while providing a quiet living or working environment. This article delves into the significance of door rubber side seals, their manufacturing processes, and what to look for in reliable factories producing these vital components.

What Are Door Rubber Side Seals?

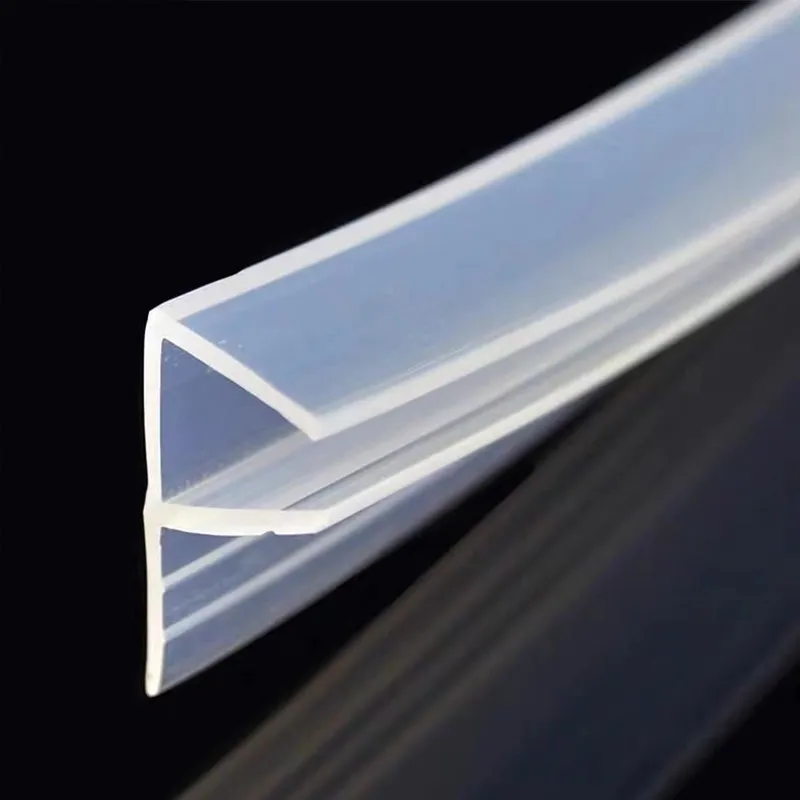

Door rubber side seals are flexible strips made from various types of rubber, designed to fit along the edges of doors. Their primary function is to prevent air leakage, thereby improving insulation and enhancing energy efficiency. By filling the gaps between the door and the frame, these seals not only keep conditioned air inside but also block outside pollutants, dust, and noise from penetrating your space.

The Manufacturing Process

The production of door rubber side seals involves several steps that ensure the quality and durability of the final product.

1. Material Selection Factories begin by choosing high-quality rubber compounds. Common materials include EPDM (Ethylene Propylene Diene Monomer), PVC (Polyvinyl Chloride), and silicone. Each material has unique properties that suit specific applications, from weather resistance to flexibility and temperature tolerance.

2. Molding and Extrusion Once the material is selected, it undergoes processes such as molding or extrusion. In molding, rubber is heated and applied to a mold to create the desired shape. Extrusion, on the other hand, involves forcing material through a die to form continuous strips that can be cut to length.

3. Curing After shaping, the rubber must be cured, a chemical process that enhances its strength and durability. Curing can involve adding sulfur or other curing agents that facilitate cross-linking, making the rubber more resilient and long-lasting.

4. Quality Control Established factories employ rigorous quality control measures. Seals are tested for elasticity, tensile strength, and resistance to environmental factors, ensuring that they will perform well in real-life applications.

door rubber side seal factories

5. Packaging and Distribution Finally, once the seals pass quality checks, they are packaged and ready for distribution. Factories often have partnerships with suppliers and distributors to ensure that their products reach the market efficiently.

Choosing the Right Factory

When it comes to selecting a factory for door rubber side seals, there are several factors to consider

- Experience and Reputation Look for factories with a solid track record in manufacturing rubber components. Reputation can often be gauged through customer reviews and industry recognition.

- Product Range A factory that offers a variety of rubber seals and customization options can meet specific needs. This is particularly relevant for businesses that require unique sizes or designs.

- Certifications Ensure the factory adheres to relevant industry standards and certifications, indicating their commitment to quality and safety.

- Sustainability Practices As consumers become more eco-conscious, consider choosing a factory that implements sustainable practices in sourcing materials and manufacturing processes.

- Customer Support Good factories provide strong customer support, helping clients with inquiries and guiding them through the ordering process.

Conclusion

In conclusion, door rubber side seals are critical components that significantly impact the energy efficiency and comfort of our environments. Factories that produce these seals play an essential role in delivering quality products that meet consumer demands. By understanding the manufacturing process and knowing what to look for in a factory, you can make informed decisions to ensure that you choose the best rubber side seals for your needs. Investing in high-quality products not only enhances comfort and efficiency but also contributes to a more sustainable future.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025