Find Reliable Rubber Seal Suppliers for Your Industrial Needs and Applications Today

Understanding the Role of Rubber Seal Suppliers in Industrial Applications

In today's fast-paced industrial landscape, the integrity of machinery and equipment is paramount. One of the critical components that ensure operational efficiency is the rubber seal. These seals play a pivotal role in preventing leaks, maintaining pressure, and protecting machinery from contaminants. Consequently, the demand for high-quality rubber seal suppliers has surged across various sectors, including automotive, aerospace, construction, and food processing.

The Importance of Rubber Seals

Rubber seals are utilized in a plethora of applications, owing to their exceptional elasticity, resilience, and resistance to environmental factors. They act as barriers that prevent the escape of fluids or gases, which is essential in hydraulic and pneumatic systems. In automotive applications, for example, rubber seals are instrumental in keeping engines and compartments sealed from air and fluid leaks. In the food industry, seals ensure that products remain uncontaminated, thus adhering to health and safety standards.

Diverse Range of Products

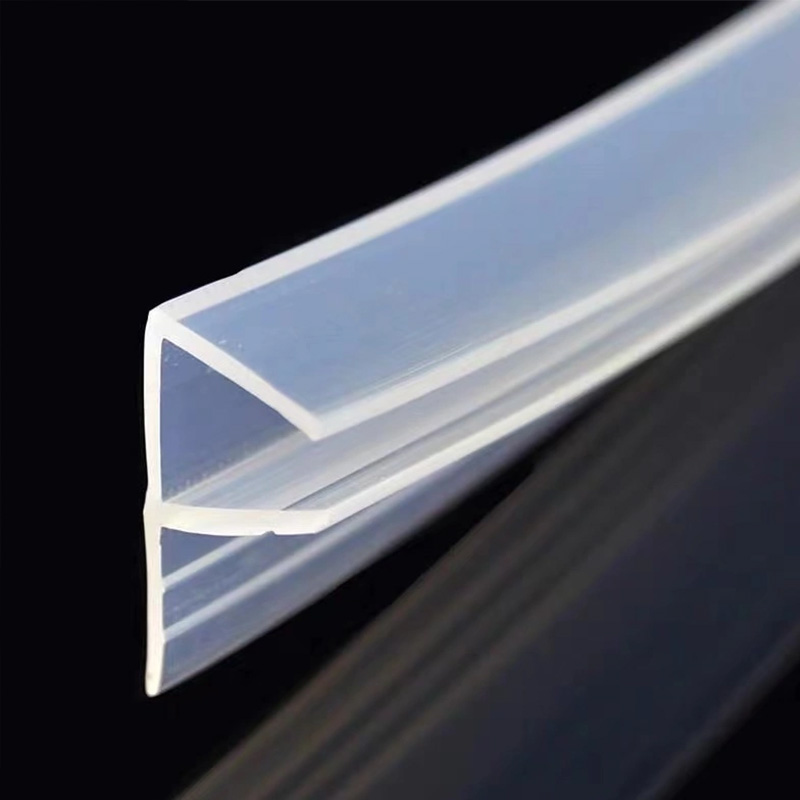

Rubber seal suppliers cater to an extensive array of needs by providing various types of seals, including O-rings, gaskets, lip seals, and custom configurations. O-rings are circular seals that fit into grooves, providing a tight seal when compressed. Gaskets are flat seals that fill spaces between surfaces to prevent leaks, while lip seals consist of a flexible edge that molds to the shaft, thereby preventing leakage of lubricants.

Moreover, suppliers often offer seals made from different rubber compounds, such as nitrile, silicone, EPDM, and viton, to meet specific requirements. For instance, nitrile rubber is commonly used in applications involving petroleum-based products due to its excellent resistance to oils and fuels. On the other hand, silicone rubber is favored in high-temperature applications, as it retains its properties even in extreme heat.

Quality and Compliance

rubber seals suppliers

One of the significant factors to consider when selecting a rubber seal supplier is quality assurance. Reputable suppliers adhere to stringent manufacturing processes and quality control standards to ensure that their products meet industry specifications. Many suppliers are certified under international standards such as ISO 9001, which signifies a commitment to consistent quality and customer satisfaction.

In addition to quality, compliance with industry regulations is crucial. Suppliers must provide seals that meet the specific needs of the industry they serve. For example, in the automotive sector, seals must comply with OEM (Original Equipment Manufacturer) specifications. In food processing, seals must be FDA-approved to ensure they do not contaminate food products.

Custom Solutions

The need for custom rubber seals has become increasingly prevalent as industries seek tailored solutions to meet unique operational challenges. Leading rubber seal suppliers offer design and engineering services that enable clients to co-develop seals that precisely fit their specifications. This customization can include variations in size, shape, and material formulation, ensuring optimal performance in diverse environments.

The Future of Rubber Seal Supply

As industries continue to evolve, the role of rubber seal suppliers will be more critical than ever. The growing emphasis on sustainability and eco-friendly materials is likely to shape future developments in rubber seal manufacturing. Suppliers that invest in research and development to create innovative, biodegradable, or recyclable seal materials will likely gain a competitive edge in the market.

In conclusion, rubber seal suppliers serve as crucial partners in maintaining the efficiency and reliability of machinery across various industries. By understanding the diverse range of products, the importance of quality and compliance, and the potential for custom solutions, businesses can make informed decisions when selecting a supplier. As technology and materials advance, the future looks promising for the rubber seal industry, with new opportunities for innovation and growth on the horizon.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025