French Door Rubber Seal – Durable, Weatherproof, Easy Fit

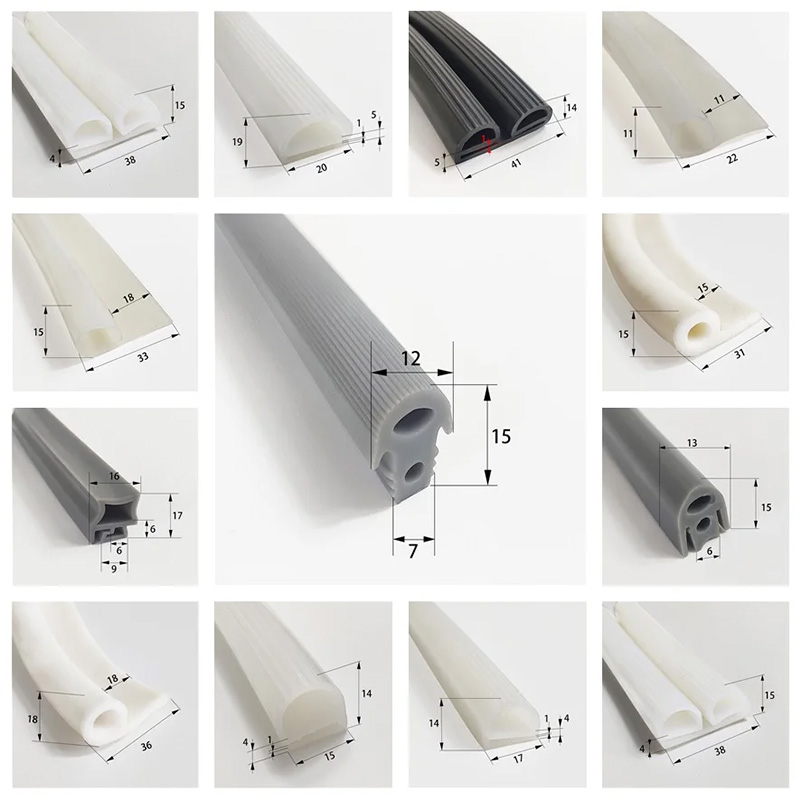

A Field Guide to the french door rubber seal (a.k.a. E Type Sealing Strip)

I’ve spent a chunk of my career poking around door factories, and—oddly enough—the humble gasket is where performance lives or dies. If you’re speccing or replacing a french door rubber seal, the E-type profile in silicone or EPDM is the quiet hero: neat compression, decent memory, tidy acoustics. Many customers say once they upgrade, the drafts “just stop.” Not magic—just smart materials and fit.

What’s trending (and why it matters)

Two trends are shaping specs right now: tighter energy codes and homeowners expecting “luxury quiet.” In fact, EPDM and silicone blends are edging out basic PVC on long-term compression set, and builders are asking for documented compliance—ASTM D2000, ISO 37/48, even EN 12365 classifications. To be honest, the market is less about the cheapest roll and more about verified performance over 8–15 years.

Product snapshot: E Type Sealing Strip

Origin: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China.

| Parameter | Spec (≈ / around / real-world use may vary) |

|---|---|

| Material options | NR, EPDM, NBR, SBR, FKM, PP, PVC, TPR, TPE, TPU, TPV, Silicone |

| Durometer | Shore A ≈ 35–75 (E-type sweet spot often 45–60A) |

| Temperature | EPDM: −40 to +120°C; Silicone: −50 to +200°C |

| Compression set | ASTM D395 @70°C, 22h: ≤25% (EPDM), ≤20% (Silicone) |

| Colors / Size | Black standard; custom colors; any size by mold per drawing |

| Adhesive option | Acrylic PSA tape backing (3M-type), peel-and-stick |

Where it’s used

French and patio doors (timber, aluminum, uPVC), balcony pairs, hospitality suites, coastal homes, cold-climate cabins, even cleanroom pass doors and light commercial storefronts. A good french door rubber seal lifts air-tightness (EN 1026/12207), water resistance (around Class 7A/8A where the frame allows), and knocks down noise ≈ 3–6 dB on typical retrofits.

How it’s made (short version)

- Compounding: polymer + fillers + curatives; tuned for low compression set and UV/ozone resistance (EPDM shines here).

- Extrusion: E-type profile die; optional co-extruded skin or foam core for softer close.

- Vulcanization/Curing: continuous; silicone via peroxide/platinum systems.

- Adhesive lamination: acrylic PSA applied with release liner.

- QA/Testing: ISO 37 tensile, ISO 48 hardness, ASTM D395 compression set; visual checks per EN 12365-1.

Service life? In real homes, EPDM is ≈ 8–12 years; silicone often 10–15, especially in high-UV coastal zones. I guess installation quality is half the battle—clean substrate, correct compression (typically 25–35%).

Vendor snapshot (what buyers compare)

| Factor | Shuoding E-Type | Generic Import | Local Fabricator |

|---|---|---|---|

| Material range | Broad (NR–FKM, Silicone) | Mixed, PVC-heavy | Selective |

| Testing docs | ASTM/ISO data provided | Varies | On request |

| Customization | Any size by mold; colors | Limited | Good, small runs |

| Lead time | Around 2–4 weeks | Uncertain | 1–3 weeks |

Mini case notes

Coastal villa pair-doors in Xiamen swapped aging PVC for silicone E-type. Customer feedback after typhoon season: “less rattling, zero visible seep.” Lab data showed compression set ≈ 18% after 22h @70°C, which tracks with the quieter latch feel. In a boutique hotel retrofit, EPDM E-type lifted door set air classification to EN 12207 Class 3; guests reported fewer corridor smells too—unexpected perk.

Certs & good-to-have paperwork

- Material classifications: ASTM D2000 (EPDM types, callouts); ISO 37/48 mechanicals.

- Compression set: ASTM D395; aging/ozone: ASTM D1149 (EPDM advantage).

- Building hardware: EN 12365 for gaskets; air/water tests via EN 1026/1027.

- RoHS/REACH statements; optional UL 94 HB for select polymers.

Last tip: pick durometer to match your hinge preload. Too hard and the door won’t latch cleanly; too soft and you lose rebound. Sounds obvious, but it trips up even seasoned installers.

References

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications.

- ISO 37 / ISO 48: Rubber, vulcanized or thermoplastic — Tensile properties / Hardness tests.

- EN 12365-1: Building hardware — Gasket and weatherstripping — Performance requirements.

- EN 1026/1027/12207: Windows and doors — Air permeability and classification; Water tightness.

- ASTM D395: Standard Test Methods for Rubber Property—Compression Set.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025