Rubber Seals for Front Door Thresholds from Trusted Manufacturers in the Industry

The Importance of Front Door Threshold Rubber Seals A Glimpse into the Factory Production Process

In the world of home improvement and construction, every minute detail plays a crucial role in enhancing the overall functionality and aesthetics of a property. One of the often-overlooked components is the front door threshold rubber seal. This simple yet essential product is designed to provide insulation, weather resistance, and a barrier against dust and insects, significantly improving the comfort and efficiency of homes. This article explores the significance of front door threshold rubber seals and provides insight into the factory processes involved in their production.

Understanding Front Door Threshold Rubber Seals

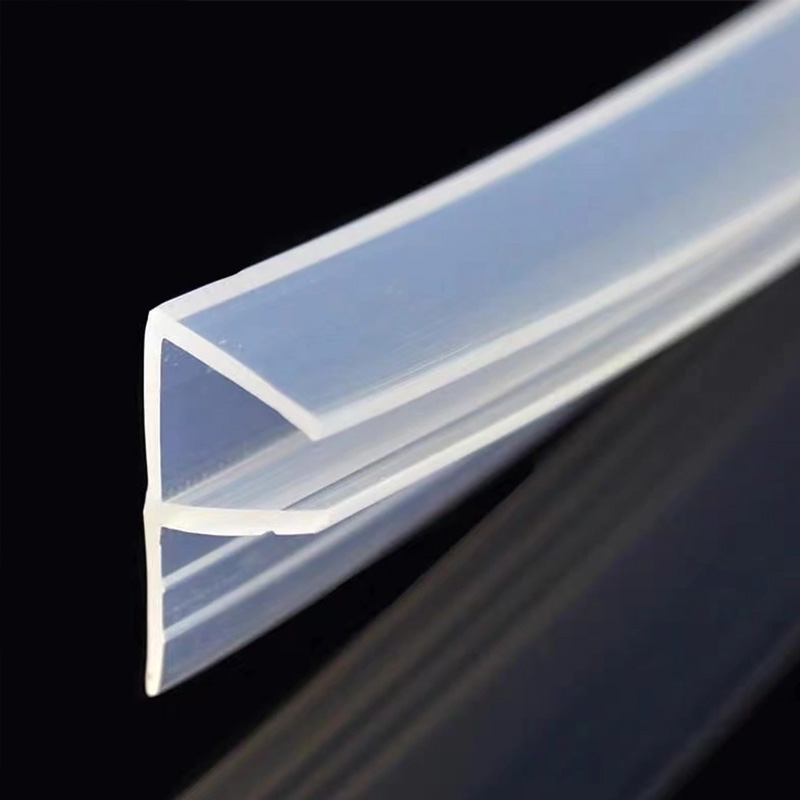

A front door threshold rubber seal typically runs along the bottom edge of a door frame, sealing the gap between the door and the floor. Its primary functions include preventing air leakage, blocking rainwater from entering, and keeping dust, dirt, and pests at bay. Moreover, these seals contribute to the home’s energy efficiency, which can substantially decrease heating and cooling costs.

The materials used in manufacturing rubber seals are vital to their performance. Most seals are made from durable, weather-resistant rubber compounds that ensure longevity and adaptability to a range of environmental conditions. Additionally, they can be designed to fit various door sizes and styles, making customization an integral aspect of their production.

The Manufacturing Process

The journey of a front door threshold rubber seal begins in the factory, where raw materials are carefully selected and processed. The manufacturing process typically involves several key stages

1. Material Selection The most common materials used in rubber seal production include natural rubber, synthetic rubber, and thermoplastic elastomers (TPE). Manufacturers carefully choose materials based on their properties, including flexibility, durability, and weather resistance.

2. Compounding Once the materials are selected, they are mixed with additives to enhance their performance. This can include colorants, antioxidants, and UV stabilizers. The compounding process is critical as it determines the elasticity and tensile strength of the final product.

front door threshold rubber seal factory

3. Molding After compounding, the rubber is placed into molds to form the desired shape of the threshold seal. There are various molding techniques, including compression molding and injection molding, each offering unique advantages in terms of efficiency and precision.

4. Curing Curing, or vulcanization, is the process by which rubber undergoes a chemical reaction to enhance its physical properties. By applying heat and pressure, the rubber's molecular structure is altered, resulting in increased strength and resistance to wear and environmental factors.

5. Quality Control After curing, each batch of rubber seals undergoes rigorous quality control checks. This includes testing for durability, resistance to extreme temperatures, and overall functionality. Testing ensures that only seals meeting the manufacturer's high standards make it to market.

6. Finishing Touches Once quality standards are met, the rubber seals are trimmed to exact specifications, packaged, and prepared for distribution. This may include additional processes like labeling, which ensures that customers receive clear information about the product.

Sustainability and Innovations

In recent years, the focus on sustainability has influenced many factories to adopt greener practices. This includes using recycled materials in production, reducing energy consumption during manufacturing, and minimizing waste. Innovations in material science are also paving the way for more eco-friendly rubber options that do not compromise on quality.

Moreover, technological advancements in automation are streamlining the production process, improving efficiency, and enabling manufacturers to meet growing consumer demands without sacrificing quality.

Conclusion

Front door threshold rubber seals may seem like small components in the grand scheme of home construction and improvement, but their impact is substantial. From enhancing energy efficiency to improving indoor comfort, these seals play a critical role in modern living. The manufacturing process behind these versatile products reflects a blend of traditional craftsmanship and modern innovation, ultimately catering to consumer needs while promoting sustainability. As homeowners continue to prioritize energy efficiency and comfort, the significance of high-quality front door threshold rubber seals will only continue to grow.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025