High-Efficiency Lithium Ion Battery Pack Assembly Line

The global shift towards sustainable energy sources has dramatically accelerated the demand for efficient and reliable energy storage solutions. At the forefront of this revolution are lithium-ion batteries, acclaimed for their high energy density, long cycle life, and broad application spectrum. As the market for electric vehicles (EVs), renewable energy integration, and residential/commercial energy storage continues to boom, the sophistication of manufacturing processes, particularly the lithium ion battery pack assembly line, becomes paramount. This article delves into the intricacies of modern battery pack production, focusing on state-of-the-art equipment and processes that define efficiency, safety, and scalability.

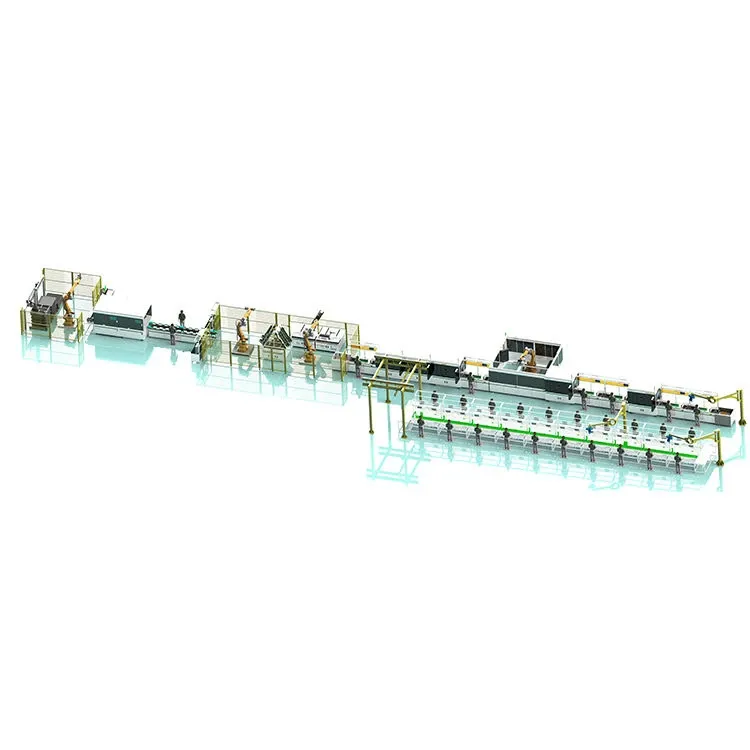

Product Focus: Industrial and Commercial/Home Energy Storage Module Laser Production Line

Our featured product, the Industrial and Commercial/Home Energy Storage Module Laser Production Line, represents the pinnacle of automated battery assembly technology. Designed for high-precision, high-volume manufacturing, this line is crucial for producing energy storage modules that power everything from grid-scale solutions to smart homes. Its integration of advanced laser technology ensures superior welding quality and production efficiency, setting new industry benchmarks.

1. Industry Trends and Market Dynamics in Battery Manufacturing

The energy storage landscape is experiencing unprecedented growth. According to BloombergNEF's 2023 Energy Storage Market Outlook, global energy storage deployments are projected to reach 588 GW/1,743 GWh by 2030, a twelve-fold increase from 2022. This rapid expansion is primarily driven by supportive government policies, declining battery costs, and the increasing intermittency of renewable energy sources. While lithium ion battery pack assembly line remains the dominant technology, there's also parallel innovation in areas such as sodium-ion batteries and solid-state batteries, though lithium-ion holds a significant lead due to its maturity and performance.

The shift from traditional energy storage solutions like the lead acid battery production line to advanced lithium-ion systems underscores the industry's demand for higher energy density, longer cycle life, and lower maintenance. This transition necessitates advanced manufacturing capabilities, highlighting the critical role of specialized lithium ion battery assembly equipment. The future of energy storage is increasingly dependent on highly automated, precise, and scalable assembly lines.

2. Technical Parameters and Core Specifications of Advanced Battery Assembly Lines

A sophisticated lithium ion battery pack assembly line integrates numerous high-precision machines, each performing a critical function. Key technical parameters define the efficiency, reliability, and output quality of such a line:

Key Technical Specifications

- Production Capacity: Typically ranges from 5-50 GWh/year for large-scale facilities. Our Industrial and Commercial/Home Energy Storage Module Laser Production Line can process up to 1000 modules per day, depending on module size and complexity.

- Assembly Speed: Measured in cells/minute or packs/hour. High-speed lines achieve 60-120 cells/minute.

- Welding Accuracy: Laser welding offers micron-level precision (±5-10 µm) for consistent, strong interconnections.

- Automation Level: Fully automated lines minimize human intervention, reducing errors and increasing throughput. This includes robotic material handling, automated quality control (QC), and data logging.

- Defect Rate: Aim for ultra-low rates, typically <0.1% for critical processes like welding.

- Energy Consumption: Optimized for efficiency, utilizing energy-saving components and intelligent power management.

- Footprint: Modular design allows for scalable solutions, optimizing space utilization.

- Compatibility: Adaptable to various cell formats (cylindrical, prismatic, pouch) and chemistries (NMC, LFP).

Comparative Analysis: Lithium Ion Battery Pack Assembly Line vs. Traditional Lead-Acid Lines

To highlight the technological leap, consider the stark differences between a modern lithium ion battery pack assembly line and a traditional lead acid battery production line:

| Feature | Lithium-Ion Battery Pack Assembly Line | Lead-Acid Battery Production Line |

|---|---|---|

| Energy Density | High (150-250 Wh/kg) | Low (30-50 Wh/kg) |

| Cycle Life | Long (2,000-10,000+ cycles) | Short (300-1,200 cycles) |

| Maintenance | Minimal, virtually maintenance-free | Regular electrolyte checks, watering |

| Assembly Process Focus | Precision welding (laser/ultrasonic), BMS integration, advanced testing, thermal management | Plate formation, acid filling, casing sealing, simpler electrical connections |

| Automation Level | Highly automated, robotic systems | Semi-automated to manual processes |

| Environmental Impact | Lower during operation, recycling infrastructure evolving | Contains lead and sulfuric acid, significant environmental concerns if not handled properly |

| Safety Mechanisms | Integrated BMS for overcharge/discharge protection, thermal runaway mitigation | Ventilation for hydrogen gas, simpler safety protocols |

| Cost (Per kWh) | Declining rapidly, becoming competitive | Historically lower initial cost, higher total cost of ownership (TCO) |

This comparison clearly illustrates why industries are rapidly migrating towards lithium-ion solutions, necessitating advanced equipment for lithium battery assembly.

3. Application Scenarios of Advanced Battery Pack Assembly Lines

The versatility of lithium-ion battery packs, produced by sophisticated assembly lines, allows them to serve a multitude of critical applications across various sectors:

- Electric Vehicles (EVs): From passenger cars to heavy-duty trucks and buses, high-performance battery packs are the heart of EVs, requiring robust, reliable, and energy-dense solutions.

- Grid-Scale Energy Storage: Supporting renewable energy integration (solar, wind) by storing excess energy and releasing it during peak demand or when generation is low, enhancing grid stability and reliability.

- Commercial & Industrial (C&I) Energy Storage: Companies use these systems for peak shaving, demand charge reduction, and backup power, significantly cutting operational costs and ensuring business continuity.

- Residential Energy Storage: Homeowners integrate battery packs with rooftop solar PV systems to achieve energy independence, reduce electricity bills, and provide backup power during outages.

- Portable Electronics & Tools: Though smaller scale, the same principles of precision assembly apply to laptops, smartphones, and power tools, ensuring safety and performance.

- Specialized Applications: Marine vessels, aerospace, defense, and telecommunications rely on custom-designed lithium-ion battery packs for demanding operational environments.

The Industrial and Commercial/Home Energy Storage Module Laser Production Line is specifically tailored for the C&I and residential sectors, producing modules optimized for these dynamic energy storage needs, highlighting its relevance as essential equipment for lithium cell assembly.

4. Technical Advantages of Laser Production Lines for Battery Assembly

The choice of manufacturing technology profoundly impacts the quality and performance of the final battery pack. Our laser production line offers distinct advantages:

- Precision Welding: Laser welding (e.g., fiber laser, YAG laser) offers superior spot size control and energy delivery compared to traditional resistance welding. This results in stronger, more consistent welds between cells and busbars, minimizing internal resistance and maximizing power output. Typical weld penetration depth can be controlled within ±10 microns.

- Minimal Heat Affected Zone (HAZ): Lasers concentrate energy precisely, leading to a very small HAZ. This is critical for battery cells, preventing damage to sensitive internal components and maintaining cell integrity, thus extending the battery's lifespan.

- High Speed & Throughput: Laser welding is inherently fast, capable of processing multiple welds per second. Combined with automated material handling, this significantly boosts the overall throughput of the lithium ion battery pack assembly line.

- Process Stability & Repeatability: Advanced control systems ensure highly repeatable welding parameters, leading to consistent product quality and reducing defect rates.

- Versatility: Lasers can weld dissimilar materials often found in battery packs (e.g., copper to aluminum), offering greater design flexibility.

- Clean Process: Laser welding is a non-contact process that produces minimal spatter or fumes, contributing to a cleaner and safer working environment.

Material and Manufacturing Excellence: Our production line incorporates robust materials engineered for longevity and precision. Key components are typically fabricated from high-grade stainless steel or aluminum alloys, ensuring stability and corrosion resistance, particularly relevant in industrial environments (e.g., chemical processing areas, water treatment plants). Manufacturing processes include precision CNC machining for critical parts, ensuring exact tolerances. For structural elements, advanced casting or forging techniques provide superior mechanical properties and durability. All components adhere to stringent quality standards, including ISO 9001 and ANSI specifications, ensuring a reliable and long-lasting operational life, typically exceeding 10-15 years with proper maintenance. This robust construction ensures the line can withstand demanding production schedules, akin to the rigorous demands in petrochemical or metallurgy industries where equipment must operate flawlessly for extended periods.

5. The Lithium Ion Battery Pack Assembly Line: Detailed Process Flow

The manufacturing of a lithium-ion battery pack is a multi-stage process requiring precision and quality control at every step. Our Industrial and Commercial/Home Energy Storage Module Laser Production Line meticulously executes these steps:

Step 1: Cell Incoming Inspection & Sorting

Description: Raw battery cells (cylindrical, prismatic, or pouch) undergo rigorous quality checks including voltage, internal resistance, capacity, and appearance. Advanced vision systems detect defects. Cells are sorted into homogeneous groups to ensure optimal pack performance and longevity. This step is critical for preventing "bad apples" from entering the production stream.

Key Technologies: High-precision cell sorters, automated optical inspection (AOI) systems, dedicated testing stations.

Step 2: Module Assembly (Cell Stacking/Fixing)

Description: Sorted cells are precisely arranged and fixed into their designated module configurations. This involves automated loading, positioning, and securing cells within module frames or trays. Thermal management components (e.g., cooling plates, thermal pads) are integrated at this stage.

Key Technologies: Robotic arms for precise placement, automated jigging and clamping systems, adhesive dispensing robots.

Step 3: Busbar Welding (Laser Welding Highlight)

Description: This is a core competency of our laser production line. Busbars (copper or aluminum strips) are laser-welded onto cell terminals to establish electrical connections within the module. Multi-axis robotic laser welding stations ensure high-speed, high-quality, and consistent welds, minimizing electrical resistance and maximizing current flow.

Key Technologies: High-power fiber lasers, galvanometer scanners for fast beam steering, sophisticated vision systems for weld seam tracking, active cooling systems for laser heads.

Step 4: BMS (Battery Management System) Integration

Description: The BMS, the "brain" of the battery pack, is integrated. This involves connecting voltage sensing wires, temperature sensors, and communication lines to the cells and the central BMS unit. The BMS monitors cell health, balances charges, and protects against overcharge, over-discharge, over-current, and extreme temperatures. Firmware is uploaded and verified.

Key Technologies: Automated wire harness routing, connector assembly robots, dedicated BMS programming and testing stations.

Step 5: Pack Enclosure Assembly & Sealing

Description: The assembled modules and integrated BMS are placed within the final battery pack enclosure. This involves automated sealing (e.g., robotic sealant dispensing, ultrasonic welding for plastic cases, or laser welding for metal cases) to ensure ingress protection (IP rating) against dust and water. Mechanical fastening and structural integrity checks are performed.

Key Technologies: Robotic material handling, automated dispensing systems for sealants, torque-controlled screwdriving robots, vision inspection for sealing integrity.

Step 6: End-of-Line (EOL) Testing & Quality Control

Description: The completed battery pack undergoes comprehensive EOL testing. This includes insulation resistance tests, voltage and current performance checks, internal resistance measurement, communication protocol verification (CAN, LIN), leak detection, and functional tests under simulated loads. Thermal imaging may be used to detect hot spots. Data is logged for traceability.

Key Technologies: Automated testing rigs, high-voltage insulation testers, power analyzers, thermal cameras, data acquisition systems.

Step 7: Packaging & Warehousing

Description: Finally, the tested and approved battery packs are prepared for shipment. This involves automated labeling, protective packaging, and palletizing. Ready for dispatch to customers or for storage.

Key Technologies: Automated labeling machines, robotic palletizers, integrated logistics software.

(This schematic represents the typical flow of an advanced lithium ion battery pack assembly line, emphasizing automation and precision at each stage.)

6. Manufacturer Comparison and Custom Solutions

Choosing the right lithium ion battery assembly equipment partner is a critical decision. While many providers offer individual machines, few possess the expertise to deliver a fully integrated, optimized production line. Our company stands out due to:

- Deep Expertise: With over a decade of experience in automated manufacturing and laser technology, we have delivered numerous successful projects globally. Our team comprises experts in mechanical engineering, electrical engineering, software development, and laser applications.

- Proven Track Record: We have successfully deployed Industrial and Commercial/Home Energy Storage Module Laser Production Lines for leading energy storage providers and EV manufacturers. (Specific client names are confidential, but our portfolio includes industry leaders.)

- Comprehensive R&D: We continuously invest in research and development to integrate the latest advancements in laser technology, robotics, and AI-driven quality control. This ensures our lines are future-proof and competitive.

- Customization & Scalability: Unlike off-the-shelf solutions, our offerings are highly customizable. We work closely with clients to design a lithium ion battery pack assembly line that precisely matches their specific production capacity, battery chemistry, form factors, and budget. Whether it's a pilot line or a gigafactory-scale setup, our modular approach ensures seamless expansion.

- Global Service & Support: Our dedicated team provides end-to-end support, from initial consultation and factory layout design to installation, commissioning, operator training, and ongoing maintenance. We offer remote diagnostics and prompt on-site technical assistance.

Why Choose Our Industrial and Commercial/Home Energy Storage Module Laser Production Line?

Our solution is not just a collection of machines; it's a meticulously engineered system designed for maximum ROI. We focus on:

- Unparalleled Precision: Achieved through advanced laser welding and vision inspection systems, leading to superior battery pack performance and safety.

- High Throughput & Efficiency: Optimized automation reduces cycle times and labor costs, significantly increasing production output.

- Flexibility: The line can be adapted to various battery chemistries (NMC, LFP, NCA), cell types (cylindrical, prismatic, pouch), and module designs, ensuring long-term utility.

- Compliance & Safety: Adherence to international standards like ISO 9001, CE, and UL certifications for all components and processes. Integrated safety features protect personnel and prevent equipment damage.

- Data-Driven Manufacturing: Real-time data collection and analysis enable predictive maintenance, continuous process improvement, and comprehensive traceability for every manufactured pack.

7. Real-World Application Cases & Success Stories

Our advanced lithium ion battery pack assembly line has been instrumental in enabling our clients to achieve their production goals and penetrate new markets. Here are illustrative examples:

Case Study 1: Large-Scale Residential ESS Manufacturer

Client Profile: A leading North American manufacturer of residential energy storage systems, aiming to scale production from 50 MWh to 500 MWh annually to meet surging demand.

Challenge: Existing semi-manual assembly methods led to bottlenecks, inconsistent weld quality, and high labor costs, hindering rapid expansion.

Our Solution: We deployed a customized Industrial and Commercial/Home Energy Storage Module Laser Production Line, specifically optimized for their 280Ah LFP prismatic cell format. The line incorporated dual-head laser welders and advanced cell sorting automation.

Outcome:

- Production Increase: Achieved a 5x increase in daily module output within 6 months of commissioning.

- Quality Improvement: Reduced welding-related defects by 85%, leading to higher overall pack reliability (as validated by ISO/TS 16949 compliant testing).

- Cost Reduction: Decreased labor costs per module by 40% through automation.

- Market Impact: Enabled the client to significantly reduce time-to-market for new product iterations and capture a larger market share.

Case Study 2: Commercial & Industrial Grid-Edge Storage Provider

Client Profile: An emerging European innovator developing modular battery container111s for commercial and industrial demand-side management and grid stabilization.

Challenge: Required a flexible lithium ion battery assembly equipment solution that could handle varying module sizes and integrate different BMS protocols for diverse project requirements.

Our Solution: We designed a highly flexible laser production line with quick-change tooling capabilities and a programmable BMS integration station. The system included advanced robotic handling for heavy module components, minimizing manual intervention.

Outcome:

- Operational Flexibility: Successfully managed three different module form factors on a single line with minimal changeover time (less than 1 hour).

- Enhanced Safety: Integrated thermal management and advanced leak detection systems ensured packs met stringent UL 1973 safety standards for stationary energy storage.

- Efficiency: Reduced overall production time per container111 by 30%, contributing to faster project deployment for the client.

- Client Feedback: "The precision and adaptability of the laser welding and assembly line are critical to our product quality and our ability to customize solutions for complex C&I projects. It truly sets us apart."

8. Frequently Asked Questions (FAQ)

Q1: What materials are typically used in the construction of your lithium ion battery pack assembly line?

A1: Our assembly lines are primarily constructed from high-grade industrial aluminum profiles for structural rigidity and precision, coupled with stainless steel components for critical interfaces and areas requiring enhanced corrosion resistance. Precision parts, especially for laser welding and robotic grippers, utilize aerospace-grade alloys and ceramics for optimal performance and longevity. All materials are selected for their durability, low maintenance, and adherence to international industrial standards such as ASTM and DIN.

Q2: What kind of manufacturing processes are employed for the equipment components?

A2: We utilize state-of-the-art manufacturing processes for our equipment components. This includes advanced CNC machining for parts requiring micron-level tolerances, precision laser cutting for complex geometries, and robotic welding for structural integrity. For larger, high-stress components, specialized forging or casting techniques may be employed, followed by heat treatment to achieve desired material properties. Surface treatments such as anodizing or powder coating ensure durability and aesthetic quality.

Q3: What are the typical dimensions and power requirements for a full Industrial and Commercial/Home Energy Storage Module Laser Production Line?

A3: The dimensions vary significantly based on the required production capacity and level of automation. A typical medium-scale line might require a footprint of approximately 500-1000 square meters (5,400-10,800 sq ft). Power requirements can range from 150 kW to 500 kW, depending on the number of laser stations, robots, and testing equipment integrated. We provide detailed utility requirements and layout drawings as part of our customization proposal.

Q4: How does your line ensure safety, especially regarding thermal runaway in lithium-ion batteries?

A4: Safety is paramount. Our lines incorporate multiple layers of safety:

- Automated Cell Sorting: Eliminates faulty cells early.

- Precise Laser Welding: Minimizes heat input and prevents micro-short circuits.

- Integrated BMS Testing: Verifies the BMS functions correctly for overcharge, over-discharge, over-temperature, and short-circuit protection.

- Thermal Management Integration: Ensures proper installation of cooling components.

- EOL Testing: Comprehensive tests including insulation resistance, leak detection, and thermal imaging to identify potential issues before deployment.

- Emergency Stop Systems: Conforming to ISO 13849, CE safety standards.

Q5: What is the estimated delivery and commissioning timeline for a new lithium ion battery pack assembly line?

A5: The timeline depends on the complexity and customization level. Generally, manufacturing and factory acceptance testing (FAT) takes 4-6 months. Shipping and customs can take 1-2 months. On-site installation and commissioning typically range from 1-3 months, leading to a total project timeline of 6-11 months from contract signing to production readiness. Expedited options are available for urgent projects.

Q6: What kind of after-sales support and warranty do you offer?

A6: We offer a comprehensive after-sales support package, including:

- Standard Warranty: A 12-24 month warranty on all equipment components, covering manufacturing defects.

- Technical Support: 24/7 remote and on-site technical support by qualified engineers.

- Spare Parts: Guaranteed availability of critical spare parts with expedited shipping options.

- Preventive Maintenance: Optional service contracts for routine inspections and maintenance to maximize uptime and extend equipment lifespan.

- Training: Detailed operator and maintenance training programs for client personnel, ensuring self-sufficiency.

Q7: Can your production line integrate with existing factory MES/ERP systems?

A7: Yes, our Industrial and Commercial/Home Energy Storage Module Laser Production Line is designed with industry 4.0 compatibility in mind. It features robust data interfaces (e.g., OPC UA, Ethernet/IP, Modbus TCP) to seamlessly integrate with existing Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and SCADA systems. This enables real-time data exchange, production monitoring, traceability, and overall factory optimization.

Ready to Optimize Your Battery Production?

Partner with us to build a future-proof lithium ion battery pack assembly line that sets new standards in efficiency, precision, and reliability. Contact us today for a customized consultation.

Explore Our Production Line Solutions

References and Further Reading:

- BloombergNEF. (2023). 2023 Energy Storage Market Outlook. [Report Snapshot]. Available at: https://about.bnef.com/new-energy-outlook/ (Note: Specific report content may require subscription/purchase.)

- Journal of Power Sources. (2022). Advances in Lithium-Ion Battery Manufacturing Technologies. [Academic Publication]. Available at: https://www.sciencedirect.com/journal/journal-of-power-sources (Access to specific articles may require subscription.)

- Energy Storage News. (2023). Global Battery Production Capacity: Trends and Challenges. [Industry News Article]. Available at: https://www.energy-storage.news/ (Navigate to relevant articles or search for topics like "battery production capacity.")

- ISO. (Current Standards). ISO 9001 Quality Management Systems. [Standard]. Available at: https://www.iso.org/iso-9001-quality-management.html

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025