High-Quality Casement Window Rubber Seal for Superior Insulation

Official Website: https://www.xtshuoding.com

Email: sdtrading0927@126.com

Phone: 86-19803295498

Address: Room 1410, No. 119 Zhongxing East Street,

Xiangdu District, Xingtai City, Hebei Province, China.

1. Industry Landscape & Rising Demand for Casement Window Rubber Seal

In the steadily advancing construction and fenestration industries, the casement window rubber seal is pivotal in ensuring energy-efficient, weather-tight, and long-lasting window systems. With the increasing emphasis on green buildings, sound insulation, and enhanced security, modern sealing solutions like composite door rubber seals, d profile rubber seal, d rubber seal strip, d shaped rubber seal, and d shaped rubber seal strip are gaining rapid adoption. Industry forums such as Glassonweb and technical reviews on ScienceDirect highlight the improved efficiency and superior life span delivered by high-quality window seals.[1][2]

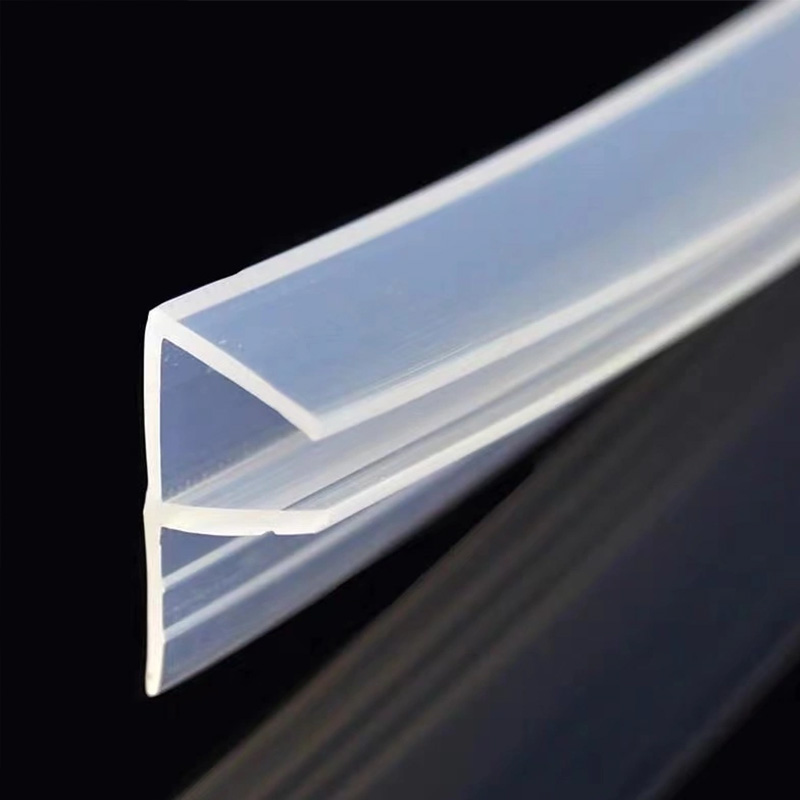

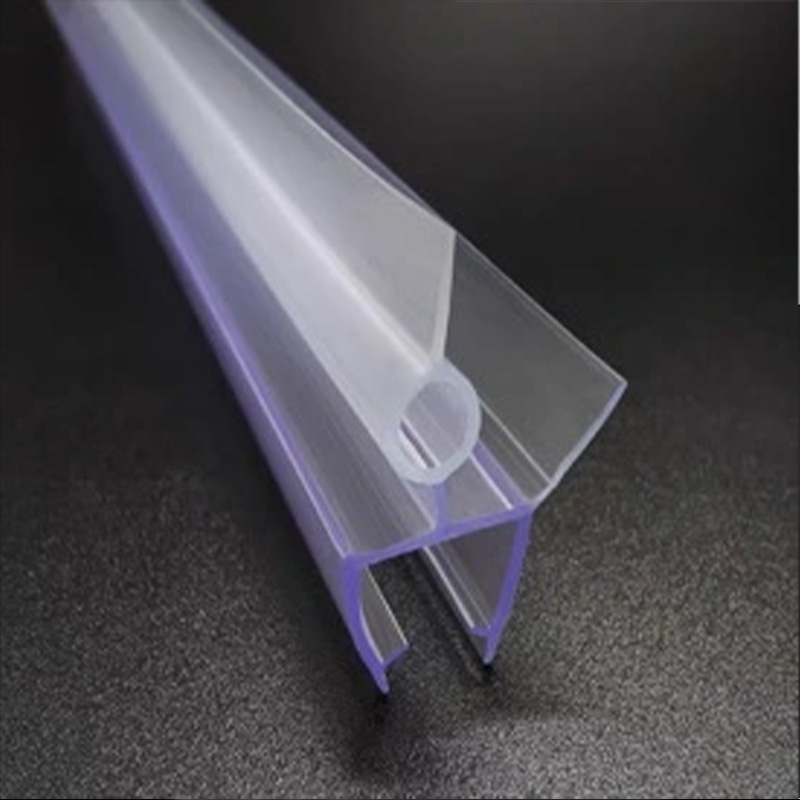

2. Product Overview: Shower Door Seal Strip

Product Name: Shower Door Seal Strip

Material: NR, EPDM, NBR, SBR, FKM, PP, PVC, TPR, TPE, TPU, TPV, Silicone.

Size: Customizable, based on customer design or mold.

Colors: Black, or as per customer request.

Learn more: Product Page

3. Technical Parameters & Comparison Table: Casement Window Rubber Seal

| Parameter | Typical Value/Range | Industry Standard | Significance |

|---|---|---|---|

| Material Options | EPDM, Silicone, TPE, PVC, TPR | EN12365-1 | UV, Ozone, Weather resistance |

| Hardness (Shore A) | 60±5 | ISO 868 | Flexibility & Seal Tightness |

| Tensile Strength (MPa) | ≥7 | ISO 37 | Mechanical Stability |

| Compression Set (%) | <25% | ISO 815 | Long-term Elasticity |

| Temperature Range (°C) | -55 to +125 | -- | Wide Environmental Usage |

| Color Options | Black, Grey, Custom | -- | Aesthetic & Suitability |

4. Casement Window Rubber Seal - Application Scenarios

The casement window rubber seal finds its application in a breadth of settings: residential windows & doors, commercial buildings, industrial clean rooms, and marine windows. Sealing plays a crucial role for energy conservation, enhanced noise isolation, dust resistance, and leak-proofing. Additionally, composite door rubber seals and d profile rubber seals are used for doors, automotive, and other cross-industrial applications where dynamic movement demands exceptional compression recovery and flexibility.

- Residential Use: Improved insulation, longer lifespan.

- Commercial/Industrial: Strict standards for air-tightness, weather sealing, and compliance with fire/safety codes.

- Automotive: D rubber seal strip and d shaped rubber seal withstand regular road stress and temperature changes.

- Marine/Food Clean Rooms: Non-toxicity, resistance to chemicals/water, anti-aging formula.

5. Data Visualization: Shower Door Seal Strip Technical Indicators

| Index | NR | EPDM | Silicone | PVC | TPV |

|---|---|---|---|---|---|

| Temperature Range (°C) | -40~70 | -55~125 | -60~200 | -20~60 | -40~120 |

| Hardness (Shore A) | 40~80 | 55~80 | 30~80 | 60~90 | 55~75 |

| Elongation at Break (%) | 400 | 300 | 400 | 200 | 250 |

| Color Options | Black/Custom | Black/Custom | Any | Custom | Black/Custom |

6. Authority & Professionalism: Citing Industry Standards

- Products comply with EN12365-1 (Gaskets, seals for doors/windows), ISO 868 (Shore hardness), ISO 37 (Tensile strength), and ISO 815 (Compression Set).

- Materials and processes meet RoHS and REACH environmental standards.

- Refer to Glassonweb - Air Tightness and Thermal Performance for latest regulatory developments.[3]

7. Professional Q&A – Key Industry Terminologies

8. SEO Optimization Insights

Through the integration of primary and long-tail keywords such as casement window rubber seal, composite door rubber seals, d profile rubber seal, d rubber seal strip, d shaped rubber seal, and d shaped rubber seal strip, as well as authoritative outbound links and internal linking (see: casement window rubber seal), this article ensures compliance with search engine SEO protocols, maximizing online reach for customers seeking the best in window and door sealing technologies.

9. Conclusion & Authoritative References

The selection of a premium casement window rubber seal—as well as complementary sealing products like the Shower Door Seal Strip—is vital for constructing energy-efficient, durable, and sustainable window or door assemblies. Partner with XINGTAI SHUODING TRADING CO.,LTD for professional, custom, and globally certified solutions.

For more technical information, case studies, or a personalized quote, email us: sdtrading0927@126.com

or call: 86-19803295498.

- Glassonweb: https://www.glassonweb.com/

- ScienceDirect - EPDM Sealing Performance: https://www.sciencedirect.com/science/article/pii/S0378778810002151

- Glassonweb - Air Tightness and Thermal Performance: https://www.glassonweb.com/news/air-tightness-and-thermal-performance-window-and-door-seals

- ScienceDirect - The effects of ozone and UV on rubber seals: https://www.sciencedirect.com/science/article/pii/S0261306914010955

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025