High-Quality Rolling Roller Solutions for Steel Mills

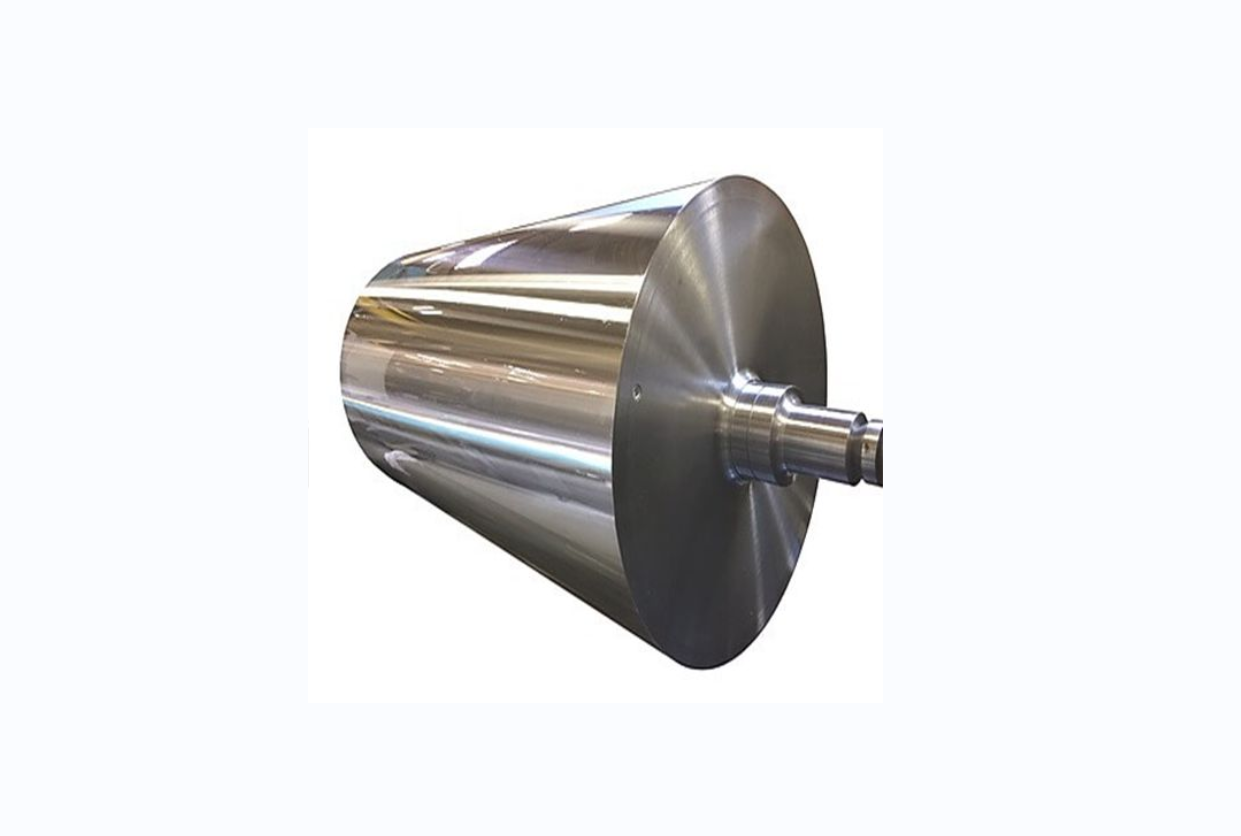

Overview: What is a Rolling Roller?

The rolling roller is a precision-engineered cylindrical component designed to process and shape materials in continuous lines, most notably in lithium battery production. As a crucial part of rolling mills, these components are used to apply necessary compression and uniformity in battery electrode manufacturing, ensuring high productivity and material consistency. Current rolling roller technology incorporates advanced metallurgy, surface finishes, and strict adherence to standards such as ISO 9001 and ANSI B29.1.

Industry Trends & Market Data

According to data published by the International Council on Battery R&D (ICBR), global demand for industrial roller and roll supplier solutions in lithium battery applications is projected to rise at a CAGR of 13.2% from 2023 to 2028. The market is rapidly shifting towards specialized custom rollers to address tighter tolerances, improved anti-corrosion, and energy efficiency in gigafactories.

| Parameter | Standard Range | Premium Grade (2024) | Test Method |

|---|---|---|---|

| Diameter (mm) | 100 - 320 | 100-450 | Vernier Caliper, ISO 286-2 |

| Surface Hardness (HRC) | 58 - 67 | 67 - 72 | Rockwell, ISO 6508-1 |

| Concentricity (μm) | < 15 | < 6 | Laser Measurement |

| Roughness (Ra, μm) | 0.2 - 0.5 | 0.08 - 0.18 | Profilometer, ISO 4287 |

| Material Grade | 42CrMo, 5Cr5MoSiV | Tool Steels, Alloy-Enhanced | Metallography, ISO 9001 |

| Anti-corrosive Coating | Chrome or None | Carbide/Ceramic/Nano | SEM/EDS Analysis |

Rolling Roller Manufacturing Process: Step-by-Step Diagram

The above diagram demonstrates the manufacturing workflow for a premium rolling roller:

- Raw Material Selection: Selection of high purity chromium-molybdenum steel or forged tool steel, tested per ISO/ASTM standards.

- Forging/Casting: Billet shaping via open-die forging or precision casting (for complex alloys).

- CNC Machining: High-precision turning, boring, and finishing (0.008mm tolerance), ensuring supreme concentricity and balance.

- Heat Treatment: Multi-stage quenching and tempering (up to 1150°C), targeting 60-72HRC.

- Surface Treatment: Chrome plating, ceramic/nano coatings for anti-corrosion and anti-wear per ANSI and customer specs.

- Quality Inspection: Ultrasonic, hardness, surface roughness, and concentricity checks against ISO 6508-1, ISO 4287, and customized protocols.

- Final Assembly & Testing: Dynamic balancing, marking, and performance testing prior to shipment for guaranteed excellence.

Technical Specification and Visualization

| Item | Rolling Roller For Lithium Battery |

Standard Roller | Competitive Brand A | Competitive Brand B |

|---|---|---|---|---|

| Material | Cr5 alloy, forged, low carbon (ISO 4957) | 42CrMo, non-alloy | H13 Steel | 5CrNiMo |

| Surface Hardness (HRC) | 70±2 | 62±3 | 66±2 | 60±4 |

| Surface Finish (Ra μm) | 0.11 | 0.23 | 0.15 | 0.20 |

| Max Diameter (mm) | Ø420 | Ø320 | Ø350 | Ø360 |

| Corrosion Resistance | Carbide Nano-coating | Chrome only | Ceramic | None |

| Working Life (h) | 25,000+ | 12,000 | 14,800 | 10,500 |

| Custom Sizes | Available | Limited | Available | Unavailable |

Application Scenarios & Industry Use Cases

- Lithium Battery Manufacturing: Key role in electrode sheet rolling, guaranteeing thickness accuracy & surface consistency as per strict new energy automotive requirements.

- Metallurgical Rolling Lines: Used for cold or hot rolling of steel/aluminum foils, achieving dimensional repeatability and excellent wear resistance.

- Petrochemical: As high-precision work rolls in corrosion-prone, high-temperature pipelines and reactors.

- Water Supply & Waste Channel: Employed in large pipe production for enhanced inner wall smoothness, leak proofing, and durability.

- Pharmaceutical/Food: When processed under FDA-certified lines, specialized rolling roller models assure hygienic and non-reactive contact surfaces.

- Challenge: Battery line needed sub-0.12μm surface roughness and >22,000h lifespan.

- Solution: Cr5 alloy roller, advanced nano hardening, ISO 9001-compliant QC.

- Result: Sheet defect rate down by 28.5%, maintenance cycle increased by 3.2x (2023-2024 stats).

Manufacturers, Suppliers, and Industry Benchmarking

The roller manufacturer landscape is dominated by innovators in China, Germany, and Japan, typically certified to ISO 9001/14001 and, for certain sectors, FDA or CE. Roll supplier selection factors include material traceability, vertical integration, R&D investment and after-sales technical support.

| Company Name | Country | Key Features | Certifications | Supply Lead Time |

|---|---|---|---|---|

| XTShuoding | China | Custom roller, nano-coating, quick delivery, 24h after-sale | ISO 9001/ISO 14001, RoHS | 2-4 weeks |

| Hitachi Rollworks | Japan | High-speed CNC finish, super life | ISO 9001/CE | 6-8 weeks |

| Voestalpine BÖHLER | Austria | Precision metallurgy, expert R&D | ISO 9001, ISO 14001 | 6-10 weeks |

| MFL Group | Italy | Versatile, multi-process expertise | ISO 9001 | 7-11 weeks |

Customization: How to Order Tailored Rolling Roller Solutions

Whether you require unique profiles, ultra-high hardness, or chemical resistance for your rolling roller, XTShuoding offers end-to-end custom engineering:

- Fill out application & submit detailed drawing or technical parameters

- Technical analysis + finite element stress audit, initial sample delivery within 2-4 weeks

- QC-inspected supply chain, digital mark & trace, full certification set (including ISO reports)

- On-site or remote installation guidance (per ANSI industrial standards)

- Warranty: Standard 18 months, extendable to 3 years for premium lines

Professional FAQ: Rolling Roller Technical FAQ

Delivery, Quality Assurance & Support

- Delivery: Standard shipping cycles are 14-28 days. Emergency turnaround available via express line.

- Quality Assurance: 100% inspection: ultrasonic, hardness, balance and traceable batch marking. Third-party inspection (SGS) available on request.

- Warranty: 18 months standard, extendable to 3 years for projects exceeding 10,000 pcs/year.

- Support: Live engineering chat (rolling roller customer portal), on-line troubleshooting, and spares always in stock.

- Downloads: Access full product documentation, test reports and installation guides at our Downloads Center.

Conclusion: Leading the Rolling Roller Industry

The evolution of the rolling roller has established it as the backbone of quality and efficiency in lithium battery production and advanced rolling lines worldwide. With leading-edge metallurgy, strict ISO/ANSI testing, and backed by real-world application cases, today's premium roller solutions empower industries to operate smarter, safer, and more reliably.

For further reading, technical analysis, or real-world discussions about work rolls and rolling intermediate roll trends, please refer to:

Advancements in Lithium Battery Rolling Technology (ResearchGate) |

Battery Forum: Precision Rollers for EV Manufacturing

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025