industrial rubber door seal factory

The Importance of Industrial Rubber Door Seals A Comprehensive Look at Their Manufacturing

In the world of industrial applications, maintaining optimal performance and protection against environmental factors is crucial. Among the myriad components that play a vital role in ensuring this protection are the industrial rubber door seals. These seals are essential in preventing contaminants such as dust, moisture, and air from entering a facility, thus safeguarding both the equipment and personnel inside. This article delves into the significance of industrial rubber door seals and explores the nuances of their manufacturing processes.

Understanding Industrial Rubber Door Seals

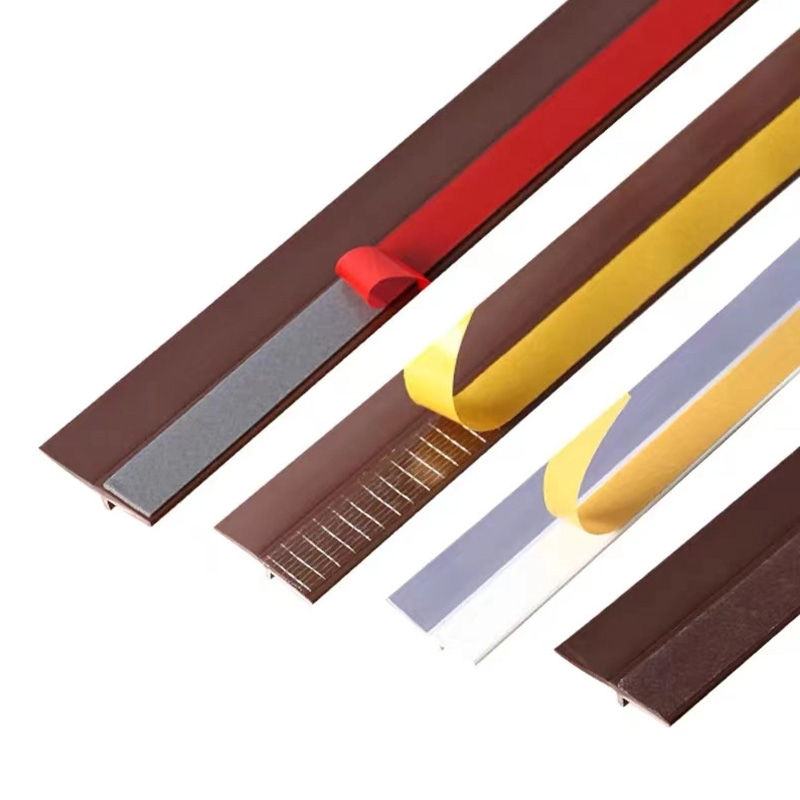

Industrial rubber door seals are designed to fit around doors in production facilities, warehouses, and commercial buildings. Their primary function is to provide a tight barrier, ensuring that external elements do not compromise the internal environment. Made from high-quality rubber materials, these seals are designed to withstand harsh conditions, including extreme temperatures and corrosive substances.

The benefits of using rubber door seals go beyond mere protection. They also contribute to energy efficiency by minimizing heat loss during temperature-sensitive operations. This is especially important in industries that rely heavily on climate control, such as food processing, pharmaceuticals, and electronics manufacturing.

The Manufacturing Process

The production of industrial rubber door seals involves several critical steps to ensure quality and durability. The first step is material selection; high-grade rubber compounds are chosen based on the application’s specific requirements, including hardness, flexibility, and resistance to chemicals.

industrial rubber door seal factory

Once the materials are selected, the manufacturing process begins with mixing. Ingredients such as rubber, fillers, and additives are combined in precise proportions to create a compound that meets performance criteria. This mixture is then subjected to a process called vulcanization, where heat and pressure are applied to transform the rubber into a durable and resilient state. This step is crucial as it enhances the elasticity and strength of the rubber, making it suitable for industrial applications.

After vulcanization, the rubber is shaped into seals using extrusion or molding techniques. Extrusion involves forcing the rubber through a die to create continuous lengths of seal material, while molding can produce seals in a variety of shapes and sizes based on specific door dimensions. Quality control is integral to the process; seal samples are tested for strength, flexibility, and dimensional accuracy to ensure they meet industry standards.

Customization and Applications

One of the significant advantages of industrial rubber door seals is the ability to customize them for specific applications. Manufacturers can create seals tailored to fit various door sizes and shapes, including sliding, hinged, and bi-fold doors. Customization extends to the choice of materials as well, enabling businesses to select seals that cater to specific environmental conditions, such as extreme temperatures or exposure to chemicals.

These seals find applications across numerous industries. In the automotive sector, they are used in assembly lines to keep contaminants away from sensitive parts. In the food and beverage industry, rubber door seals ensure that hygiene standards are met by preventing pest ingress. Moreover, in cleanrooms and laboratories, these seals help maintain controlled environments essential for sensitive research and production processes.

Conclusion

Industrial rubber door seals may appear to be a small component in the vast machinery of industrial operations, but their importance cannot be understated. From ensuring energy efficiency to safeguarding sensitive environments, these seals play a pivotal role in enhancing operational integrity. With advancements in manufacturing processes, the durability, and customization options for these seals will only continue to grow, solidifying their status as an indispensable element in various industrial applications. The commitment to quality and innovation in the manufacturing of industrial rubber door seals ultimately contributes to the efficiency and safety of industries worldwide.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025