Jan . 20 , 2025 07:10

Back to list

industrial slitting machines

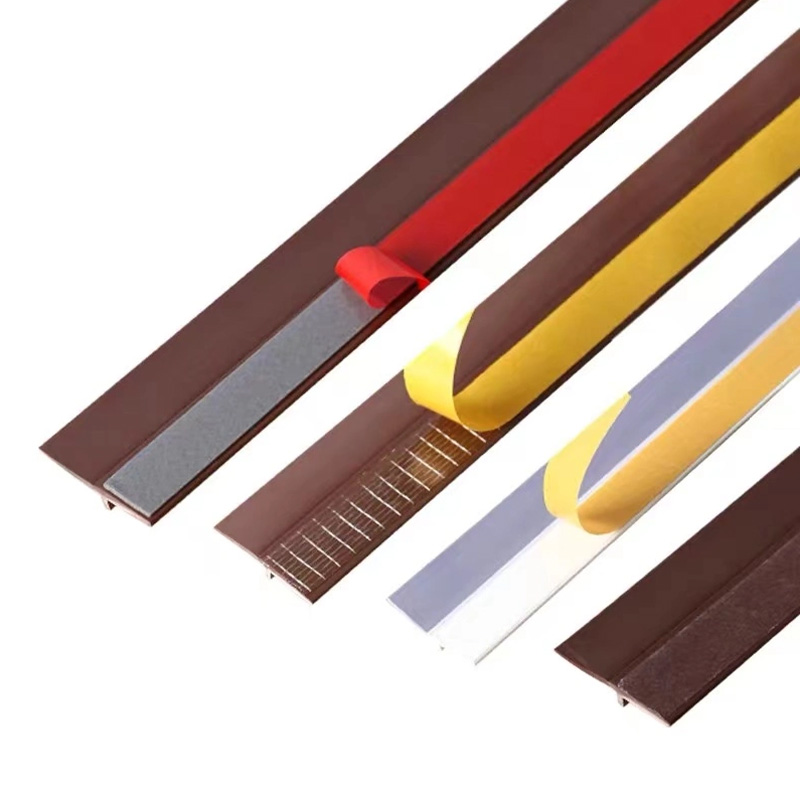

Industrial slitting machines are pivotal to the manufacturing process, ensuring precision and efficiency across various industries. These machines, integral to cutting large rolls of material into narrower strips, find applications in sectors ranging from paper and textiles to plastics and metal processing.

Moreover, the real-world experiences of operators using these machines provide invaluable insights into their functionality and reliability. Feedback from the field—gleaned from machine operators and maintenance teams—often highlights areas of strength such as user-friendly interfaces and routine maintenance requirements. These insights are essential for continual product improvement and development, ensuring that slitting machines remain at the forefront of industrial technology. Another significant consideration is the after-sales support and services offered by manufacturers. A robust support system, including readily available spare parts, technician expertise, and comprehensive warranty services, reflects the manufacturer's confidence in their product and long-term commitment to client success. In terms of expertise, selecting the right slitting machine demands comprehensive knowledge not only of the machine's specifications but also of the materials being processed. Factors like tensile strength, thickness, and material behavior under stress all play a role in determining the optimal machine for the job. Manufacturers who provide detailed technical manuals, training workshops, and knowledgeable customer service representatives exemplify industry expertise, assisting buyers in making informed purchasing decisions. Every decision in an industrial setting involves balancing upfront costs with long-term value and productivity gains. Thus, investing in a high-quality slitting machine becomes synonymous with strategic business advancement. As such, reputable manufacturers often focus on long-term partnerships; their machines are not just pieces of equipment but crucial components of the client's production line, promising enhancements to their overall operational capacity. In conclusion, industrial slitting machines embody the intersection of engineering excellence, technological innovation, and reliable manufacturing standards. Companies that prioritize precision, efficiency, and customer-focused solutions will find themselves leading the way in their respective industries, backed by machines that are as committed to their success as they are.

Moreover, the real-world experiences of operators using these machines provide invaluable insights into their functionality and reliability. Feedback from the field—gleaned from machine operators and maintenance teams—often highlights areas of strength such as user-friendly interfaces and routine maintenance requirements. These insights are essential for continual product improvement and development, ensuring that slitting machines remain at the forefront of industrial technology. Another significant consideration is the after-sales support and services offered by manufacturers. A robust support system, including readily available spare parts, technician expertise, and comprehensive warranty services, reflects the manufacturer's confidence in their product and long-term commitment to client success. In terms of expertise, selecting the right slitting machine demands comprehensive knowledge not only of the machine's specifications but also of the materials being processed. Factors like tensile strength, thickness, and material behavior under stress all play a role in determining the optimal machine for the job. Manufacturers who provide detailed technical manuals, training workshops, and knowledgeable customer service representatives exemplify industry expertise, assisting buyers in making informed purchasing decisions. Every decision in an industrial setting involves balancing upfront costs with long-term value and productivity gains. Thus, investing in a high-quality slitting machine becomes synonymous with strategic business advancement. As such, reputable manufacturers often focus on long-term partnerships; their machines are not just pieces of equipment but crucial components of the client's production line, promising enhancements to their overall operational capacity. In conclusion, industrial slitting machines embody the intersection of engineering excellence, technological innovation, and reliable manufacturing standards. Companies that prioritize precision, efficiency, and customer-focused solutions will find themselves leading the way in their respective industries, backed by machines that are as committed to their success as they are.

Share

Previous:

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025