lithium ion battery manufacturing machine

The Rise of Lithium-Ion Battery Manufacturing Machines

In recent years, the demand for lithium-ion batteries has skyrocketed, driven by the burgeoning markets of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Central to this growth is the sophisticated machinery used in the manufacturing of these batteries. This article explores the significance of lithium-ion battery manufacturing machines, the technologies involved, and their impact on production efficiency and sustainability.

Importance of Lithium-Ion Batteries

Lithium-ion batteries are the backbone of modern technology. Their high energy density, lightweight nature, and ability to recharge have made them the preferred choice for electric vehicles, smartphones, laptops, and other portable devices. As the world shifts towards greener energy solutions to combat climate change, the role of lithium-ion batteries becomes ever more critical. This creates an immense need for their production, highlighting the importance of advanced manufacturing machinery.

Overview of Manufacturing Machines

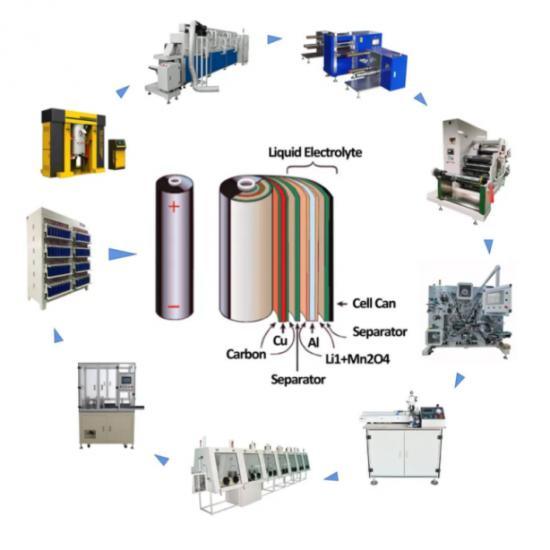

The manufacturing of lithium-ion batteries involves several key processes, including electrode production, cell assembly, and final packaging. Each of these steps requires specialized machinery designed to maximize efficiency and ensure high-quality output.

1. Electrode Production Machines The first step in battery manufacturing involves creating the cathode and anode materials. Machines used in this process typically include mixing, coating, and drying equipment. The slurry mixing machine combines active materials, solvents, and binders to create a uniform paste. Coating machines then apply this paste to metallic foils, which are subsequently dried to remove solvents, ensuring optimal performance.

2. Cell Assembly Machines Once the electrodes are prepared, they need to be assembled into cells. This is done in a highly controlled environment to avoid contamination. Assembly machines utilize robotics for precision stacking of the electrodes and separators, followed by the injection of electrolyte. This automation not only speeds up the process but also minimizes human error and improves product consistency.

3. Formation and Testing Equipment After assembly, the cells undergo a formation process where they are charged and discharged to improve their electrochemical performance. Testing equipment ensures that each cell meets stringent quality control standards by assessing parameters like capacity, voltage, and internal resistance. This step is crucial to guarantee the safety and reliability of the batteries, especially in applications like electric vehicles.

lithium ion battery manufacturing machine

4. Packaging Machines The final stage involves packaging the cells in a manner that minimizes damage and maintains safety during transport. High-speed packaging machines can efficiently handle this task, ensuring that products are ready for distribution quickly and securely.

Technological Innovations

The field of lithium-ion battery manufacturing is evolving rapidly, driven by technological advancements. Innovations such as artificial intelligence (AI) and machine learning are making manufacturing processes more intelligent and adaptive. These technologies can analyze data in real-time, enabling predictive maintenance of machines and optimizing production schedules to reduce downtime.

Furthermore, the adoption of Industry 4.0 principles in manufacturing facilities allows for greater integration of machines, materials, and systems. Smart factories equipped with IoT (Internet of Things) technologies monitor production parameters and adjust operations automatically to enhance efficiency.

Sustainable Manufacturing Practices

As the demand for lithium-ion batteries grows, so does the focus on sustainable manufacturing practices. Companies are increasingly investing in energy-efficient machines and processes that minimize waste and reduce carbon footprints. Recycling technologies are being integrated into production lines to reclaim valuable materials from used batteries, thereby promoting a circular economy.

Conclusion

The manufacturing of lithium-ion batteries plays a crucial role in supporting the transition towards renewable energy and sustainable technologies. Advanced manufacturing machines are at the heart of this process, facilitating high-quality production and ensuring the reliability of batteries that power our future. As new technologies emerge and the industry continues to innovate, the efficiency, sustainability, and overall capability of lithium-ion battery manufacturing will only improve, further driving the growth of this essential market. The future is bright for lithium-ion battery manufacturing, and the machines that make it possible are central to this exciting evolution.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025