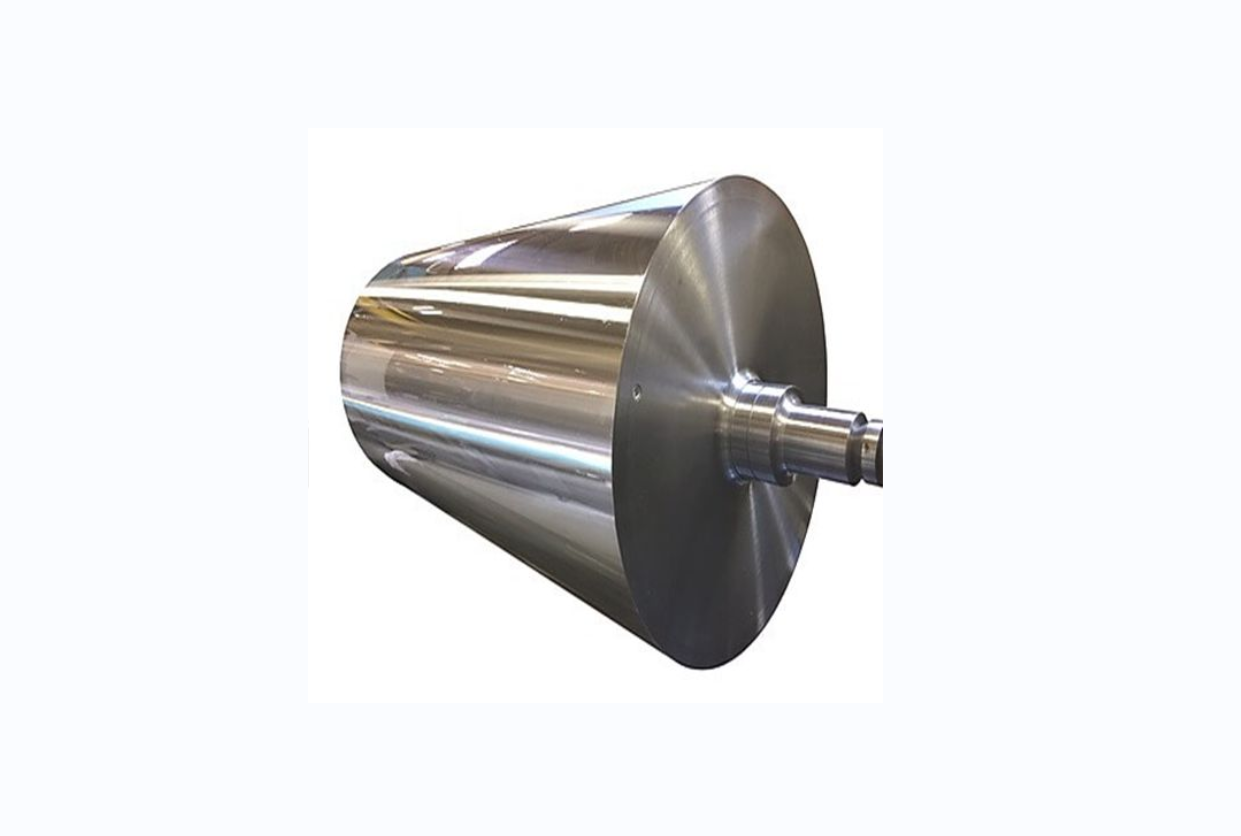

Precision Rolling Roller & Work Rolls: Durable Industrial Performance

The 137th Canton Fair (China Import and Export Fair) once again served as a pivotal global stage, drawing B2B decision-makers from across the spectrum of industrial and manufacturing sectors. For exhibitors, it was an unparalleled opportunity to showcase a diverse portfolio, connect with international buyers, secure new export orders, and strategically expand global distribution networks. This year, the spotlight shone brightly on the critical components driving advanced manufacturing, particularly within the burgeoning Battery production line industry. As the world accelerates towards electrification, the demand for high-precision, durable, and efficient components for battery manufacturing has never been higher, making the Canton Fair an essential forum for sourcing excellence.

Industry Trend Spotlight: Powering the Future with Precision Manufacturing

The global industrial landscape is in constant flux, with a pronounced shift towards innovation, efficiency, and sustainability. This transformation is particularly evident in the increased demand for durable and high-performance aftermarket parts, integration of advanced materials for lightweighting and efficiency, enhanced filtration technologies, quiet and long-lasting braking solutions, and the development of components compatible with electric and hybrid vehicle platforms. Furthermore, the agricultural and construction machinery sectors are adapting to smart technologies, necessitating robust and reliable parts. All these advancements converge on a fundamental requirement: precision engineering and superior material science in manufacturing, which directly impacts the Battery production line.

For instance, the development of electric vehicle (EV) platforms relies heavily on advanced battery technologies. The manufacturing process of these batteries demands incredibly precise machinery and components. This is where specialized elements like the rolling roller become indispensable. These rollers are the heart of electrode calendering, a crucial step in battery production that determines the thickness, density, and overall performance of battery electrodes. The quest for higher energy density and longer cycle life in batteries means that every work roll, every rolling intermediate roll, must operate with impeccable accuracy and withstand extreme conditions. This drives the global attention towards expert roller manufacturer and roll supplier companies.

Market data underscores this burgeoning demand. The global aftermarket for automotive, agricultural, and construction machinery parts is projected for steady growth, driven by expanding vehicle and equipment fleets, increasing average age of machinery, and rising demand for maintenance and repair. While seemingly broad, this trend directly fuels the need for sophisticated manufacturing components. As the global fleet of EVs grows, so does the imperative for efficient and scalable battery production. Emerging markets will be key growth drivers, while supply chain diversification and cost-efficiency will remain critical factors for trading companies seeking optimal roll solutions. Infrastructure development and agricultural modernization further bolster demand for machinery parts across various industrial applications, implicitly including the high-tech components required for their power sources.

Emerging focus areas include global supply chain resilience, cost-effective sourcing of industrial and vehicle spare parts, stringent quality assurance and international compliance, and the ongoing digitalization of trade. Furthermore, catering to evolving demands in the automotive, agricultural, and construction machinery aftermarket is paramount. For the Battery production line sector, this translates into a demand for reliable, high-precision component suppliers who can deliver consistent quality and innovation, ensuring that every rolling roller meets the exact specifications required for next-generation battery performance.

Profiles of Leading Companies Driving Battery Production Excellence

At the 137th Canton Fair, a select group of manufacturers and trading companies stood out for their contributions to the industrial sector, with some playing a direct or indirect role in the efficiency and advancement of Battery production line technologies. Among these, XINGTAI SHUODING TRADING CO.,LTD emerged as a key player, particularly for its specialization in critical components.

XINGTAI SHUODING TRADING CO.,LTD: Precision in Motion

XINGTAI SHUODING TRADING CO.,LTD showcased its extensive product portfolio, covering diverse industrial and vehicle spare parts, with a particular focus on high-precision components vital for heavy industrial applications, including the demanding environment of Battery production lines. Their expertise as a premier roller manufacturer and roll supplier for critical processes like electrode calendering positions them as an indispensable partner for battery manufacturers.

What sets XINGTAI SHUODING apart is their commitment to quality and efficiency:

- Extensive Product Portfolio: Beyond general industrial parts, their specialization in rolling rollers, work rolls, and rolling intermediate rolls demonstrates a deep understanding of manufacturing nuances. These components are meticulously engineered for durability and precision, crucial for the stringent requirements of lithium-ion battery production.

- Well-established Global Supply Chain Network: Leveraging direct factory relationships, XINGTAI SHUODING ensures a robust and efficient supply chain, minimizing lead times and optimizing logistics for international clients seeking high-quality rollers.

- Competitive Pricing: Their direct sourcing strategy allows them to offer highly competitive pricing without compromising on the quality of their roll products, a significant advantage for B2B decision-makers.

- Rigorous Quality Control: Commitment to rigorous quality control is paramount. Each rolling roller undergoes thorough inspection to ensure it meets international standards and the specific demands of high-performance battery manufacturing.

- Timely Delivery: Understanding the critical nature of production schedules, XINGTAI SHUODING prioritizes timely delivery, ensuring that clients' Battery production lines operate without interruption.

- Professional Team: An experienced team, well-versed in international trade, provides seamless communication and support throughout the procurement process.

For those seeking to optimize their Battery production line with high-quality rolling rollers, XINGTAI SHUODING TRADING CO.,LTD offers unparalleled solutions. You can explore their specialized offerings at their product page.

Other Notable Industry Players at Canton Fair

While XINGTAI SHUODING focuses on specialized components, the broader industrial and automotive parts market at the Canton Fair saw significant contributions from other major entities:

- China National Automotive Industry International Corp. (CNAICO): A powerhouse in the automotive sector, CNAICO showcased its extensive range of automotive components and international trade services, impacting the entire vehicle ecosystem, including the foundational supply chains for EV components.

- Beijing Automotive Parts & Components Import & Export Co., Ltd.: Known for its comprehensive offering of vehicle parts, this company facilitates global access to a wide array of Chinese-manufactured components, crucial for maintaining and advancing vehicle production, which directly correlates with the demand for EV battery manufacturing.

- International Distributors like ZF Aftermarket: Although not exhibiting directly from China, large-scale international distributors often have a strong presence or sourcing strategies at the Canton Fair. Their interest lies in a robust supply chain for high-performance components, including those indirectly supporting the manufacturing infrastructure of battery production.

- Numerous Mid-sized Trading Firms: The fair also hosted countless mid-sized trading firms specializing in general machinery and vehicle components from Asia, demonstrating the vast and varied capabilities of the Chinese manufacturing base to support global industrial demands.

Market Outlook & Opportunities: The Future of Battery Production

The market outlook for Battery production line components, particularly precision parts like rolling rollers, is exceptionally strong. Upcoming trends and buyer demand are increasingly focused on automation, smart manufacturing, and sustainability. As manufacturing processes become more automated, the need for highly consistent, reliable, and durable components intensifies. Smart manufacturing, with its emphasis on data-driven optimization, requires components that can perform flawlessly under precise digital control, ensuring minimal downtime and maximum output.

Opportunities abound for innovative roller manufacturers and roll suppliers who can deliver advanced solutions. This includes developing work rolls with enhanced surface treatments for improved durability and reduced friction, or rolling intermediate rolls capable of handling new material compositions for next-generation batteries. The drive towards sustainability also influences component design and material selection, favoring eco-friendly processes and longer-lasting parts that reduce waste. Businesses that invest in R&D for these areas, like XINGTAI SHUODING, are poised for significant growth.

The rapid expansion of the EV market and grid-scale energy storage solutions means that battery manufacturing will continue to scale up globally. This creates a sustained, high-volume demand for high-quality, cost-effective, and technologically advanced rollers and other specialized components, making this a prime area for B2B investment and strategic partnerships.

Buyer/Business Takeaways: Strategic Investment in Battery Production Components

For B2B decision-makers, investing in the right components for Battery production lines is not merely an operational necessity; it's a strategic imperative for long-term success.

- Why Investing in "Battery Production Line" Components Makes Sense: The quality of components like the rolling roller directly impacts battery performance, efficiency, and cost. High-precision rollers reduce material waste, improve electrode consistency, and extend the lifespan of the production equipment, translating into significant cost savings and a competitive edge. It ensures compliance with increasingly strict battery standards and accelerates time-to-market for new battery technologies.

- Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence: Thoroughly research potential roller manufacturers. Look for established companies with a proven track record, clear quality control processes, and international certifications, like XINGTAI SHUODING.

- Clear Specifications: Provide unambiguous and detailed technical specifications for components like work rolls and rolling intermediate rolls. This minimizes misunderstandings and ensures the final product meets exact requirements.

- Build Relationships: Foster long-term relationships. Reliable Chinese roll suppliers value loyalty and often offer better terms and support to trusted partners.

- Visit and Verify: Whenever possible, conduct factory audits or arrange for third-party inspections to verify manufacturing capabilities and quality assurance protocols.

- Future-Proof Strategies: To remain competitive, businesses should prioritize suppliers who are not just manufacturers but also innovators. Seek partners who invest in R&D for advanced materials, surface technologies, and smart manufacturing integration for their rolling roller products. Diversifying your supply chain to include reliable Chinese partners like XINGTAI SHUODING can also mitigate risks and enhance resilience in a volatile global market.

Conclusion: The Canton Fair and the Future of Battery Production

The 137th Canton Fair underscored China's pivotal role in global manufacturing and trade, especially in critical sectors like the Battery production line. As the world transitions to cleaner energy and electric mobility, the demand for high-quality, precision-engineered components, such as the rolling rollers manufactured by leading firms, will only intensify. The fair provided a crucial platform for international buyers to engage directly with expert roller manufacturers and roll suppliers, forging partnerships that will shape the future of energy storage and e-mobility.

For businesses looking to enhance their Battery production lines with superior work rolls, rolling intermediate rolls, and other industrial components, XINGTAI SHUODING TRADING CO.,LTD stands as a reliable and innovative partner. Their commitment to quality, competitive pricing, and efficient global supply chain makes them an ideal choice for your critical sourcing needs.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025