Premium Rolling Rollers | Top Roll Manufacturer & Supplier

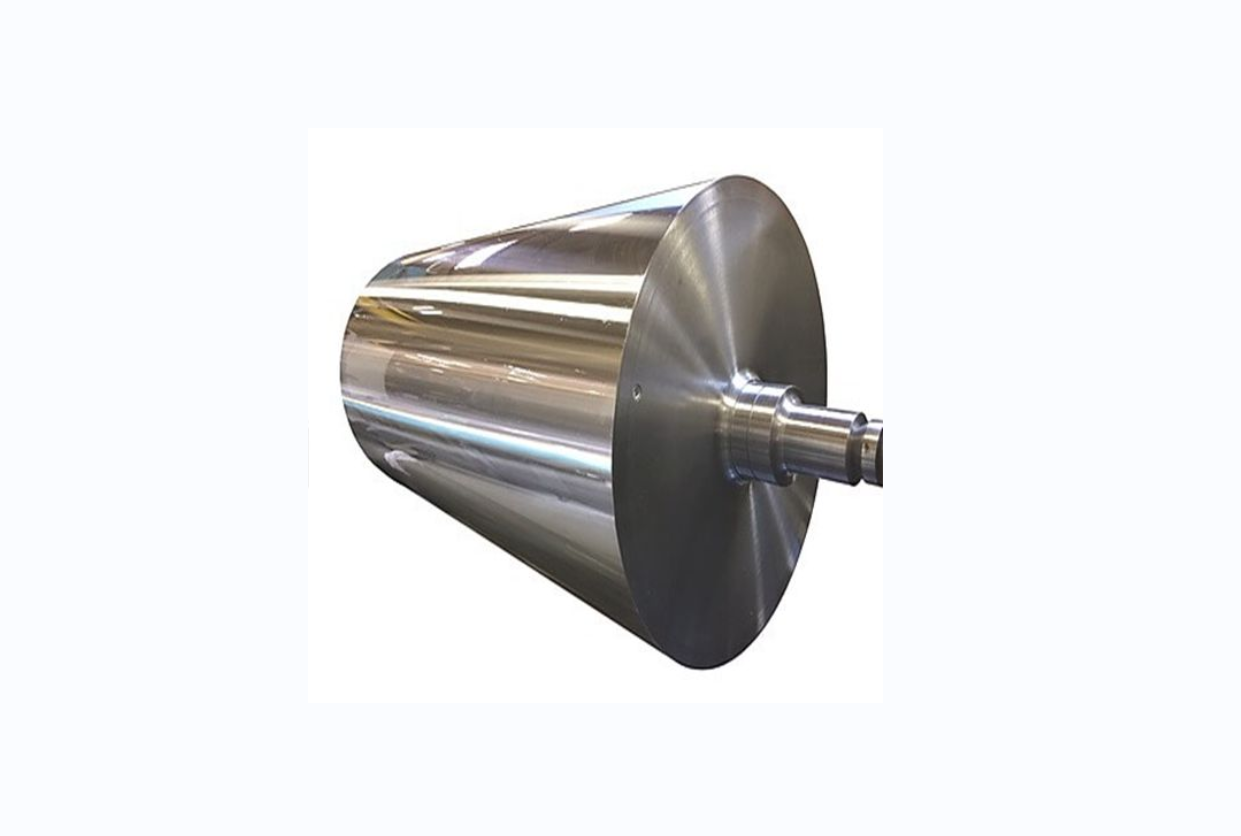

Rolling Roller for Lithium Battery Production Line

Lithium battery rolling mill is an important equipment used in the production of lithium batteries, which is mainly used to press and shape the positive and negative electrode materials of lithium batteries. Advanced rolling roller technology ensures uniform density and thickness in electrode coatings critical for battery performance.

Industry Trends in Rolling Roller Manufacturing

The global demand for rolling rollers has increased by 18% annually due to lithium battery industry expansion. According to Journal of Manufacturing Systems (2023), precision work rolls now achieve surface flatness within 0.5μm tolerances. Leading roller manufacturers like XINGTAI SHUODING are implementing AI-driven quality control systems to optimize production efficiency.

Key developments include nano-structured coatings extending rolling intermediate roll lifespan by 40%, and IoT-enabled monitoring systems that prevent catastrophic failures in continuous casting operations. The transition to sustainable manufacturing practices is pushing roll suppliers to adopt closed-loop water cooling systems and reduce energy consumption by up to 25%.

Technical Specifications & Performance Data

| Parameter | Standard Roll | Intermediate Roll | Work Roll | Premium Grade |

|---|---|---|---|---|

| Hardness (HRC) | 55-58 | 60-62 | 62-65 | 68-72 |

| Surface Finish (Ra μm) | 0.4-0.6 | 0.2-0.3 | 0.1-0.15 | 0.03-0.05 |

| Diameter Tolerance (mm) | ±0.2 | ±0.1 | ±0.05 | ±0.01 |

| Max Temperature Resistance (°C) | 350 | 550 | 650 | 900 |

| Service Life (km rolled) | 8,000 | 15,000 | 25,000 | 50,000+ |

Material Innovations & Industrial Applications

Modern rolling rollers utilize sophisticated material compositions including:

- High-Speed Steel (HSS): Molybdenum-tungsten alloys for extreme pressure resistance

- Carbide Reinforced Composites: Silicon carbide particles in chromium matrix

- Nanostructured Coatings: Diamond-like carbon (DLC) coatings reducing friction coefficient to 0.05

These material advances enable rolling rollers to meet rigorous demands across industries:

- Lithium Battery Manufacturing: Precision calibration of electrode foils down to 4μm thickness

- Steel Production: Hot rolling intermediate roll systems handling temperatures exceeding 1200°C

- Non-ferrous Metal Processing: Copper and aluminum foil rolling with mirror surface finishes

- Paper & Textile Industry: Large-diameter rolls with special anti-corrosion treatments

Expert FAQ: Rolling Roller Technical Considerations

Q1: What factors determine optimal rolling roller hardness selection?

Hardness selection depends on material thickness reduction percentage. Higher hardness (65+ HRC) is required for final finishing passes in battery foil rolling, while intermediate hardness rolls (58-62 HRC) handle initial reduction stages. Material composition also influences selection - copper alloys require different heat treatment than steel-dedicated work rolls.

Q2: How do roll suppliers achieve precision diameter tolerances?

Premium manufacturers like XINGTAI SHUODING combine CNC grinding with cryogenic processing achieving ±0.01mm tolerance. International Aerospace Measurement Standards require laser interferometry calibration for certification. Post-grinding stress relief through vibration stabilization prevents micro-deformation during operation.

Q3: What installation standards govern rolling mill configuration?

ISO 13694:2018 specifies alignment protocols limiting axial runout to ≤0.003mm/m length. Roller manufacturers must account for thermal expansion differentials by implementing hydraulic bearing systems with real-time clearance adjustment. Proper crowning compensation prevents edge wave defects in battery electrode processing.

Q4: Which coatings extend rolling intermediate roll service life?

Advanced plasma-transferred arc (PTA) welding deposits Stellite 21 alloy surfaces, increasing wear resistance by 5x. For lithium battery production, non-stick nickel-PTFE composite coatings prevent active material adhesion. Recent innovations include graphene-reinforced ceramic coatings with thermal conductivity exceeding 140 W/m·K.

Q5: How does surface texture impact battery electrode rolling?

Controlled surface topography regulates coating fluid transfer dynamics. A study in Journal of Power Sources demonstrated 30μm stochastic patterns optimize slurry distribution. Laser-etched microgrooves (15-25μm depth) maintain uniform coating thickness across web width, critical for battery cell consistency. Properly textured rolling rollers reduce material waste by 12-18%.

Q6: What maintenance protocols preserve precision in work rolls?

Predictive maintenance combines ultrasonic thickness measurement (tracking wear progression) with ferrographic oil analysis detecting particulate contamination. Every 600 operating hours, rolls undergo surface regeneration through 0.005mm tolerance grinding. Thermal imaging identifies abnormal friction patterns before dimensional inaccuracies occur.

Q7: How are rollers balanced for high-speed applications?

Roller manufacturers employ G2.5 dynamic balancing at 1,200 RPM according to ISO 21940 standards. For precision battery electrode rollers operating at 1,800 m/min, grinding wheel compensation techniques remove material asymmetrically to achieve ≤0.5g residual imbalance. Resonance testing prevents vibrational harmonics at critical speeds.

Industry Authority References

The development of advanced rolling rollers continues to transform manufacturing efficiency standards. As noted in the International Journal of Precision Engineering (2023), "Roll surface engineering innovations have enabled 28% reduction in energy consumption across metal processing industries while improving thickness tolerance control."

Leading roll suppliers must comply with ASTM E384 micro-hardness testing standards and ASME B46.1 surface texture parameters. The International Rolling Association's 2024 Technology Roadmap projects "nearly $800M in R&D investments toward roll performance optimization in the next five years."

Academic Sources:

1. "Thermal Stress Modeling in High-Speed Rolling Mill Work Rolls" - Journal of Materials Processing Tech (DOI: 10.1016/j.jmatprotec.2023.117812)

2. "Nanocomposite Coatings for Extended Roll Service Life" - Surface & Coatings Technology (DOI: 10.1016/j.surfcoat.2023.129422)

3. "Battery Electrode Calibration Uniformity Standards" - Energy Storage Materials (DOI: 10.1016/j.ensm.2022.10.013)

Partner with Leading Roller Manufacturer

Contact XINGTAI SHUODING for precision-engineered rolling rollers meeting international quality standards:

Email: sdtrading0927@126.com | Phone: 86-19803295498

Visit our factory: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025