prismatic cell manufacturing equipment exporters

The Growth of Prismatic Cell Manufacturing Equipment Exports

As the global demand for renewable energy sources continues to surge, the need for efficient energy storage solutions has never been more pressing. Prismatic cells, a type of lithium-ion battery, have become increasingly popular due to their high energy density and compact form factor. This article delves into the complexities and developments surrounding prismatic cell manufacturing equipment exporters and their crucial role in fostering a sustainable energy future.

Understanding Prismatic Cells

Prismatic cells differentiate themselves from cylindrical and pouch cells primarily in their design. Their flat, rectangular shape allows for better packing efficiency, making them an ideal choice for various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems. These cells can be stacked or arranged in battery packs, optimizing space usage and performance capabilities. Consequently, the rise in electric vehicles and renewable energy systems has led to a robust demand for prismatic cells, directly impacting the manufacturers and exporters of the specialized equipment needed to produce them.

The Role of Manufacturing Equipment

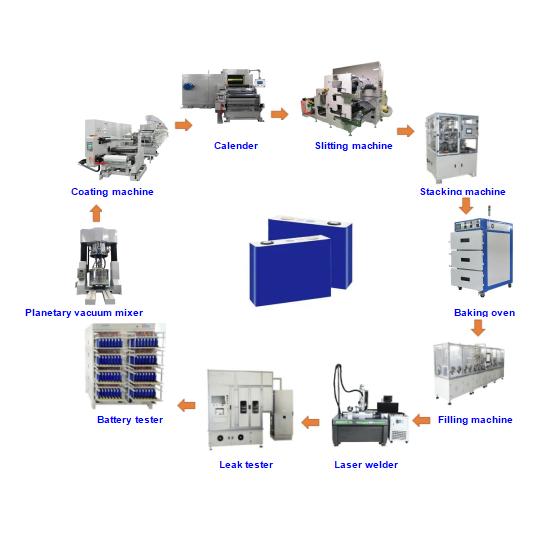

The manufacturing of prismatic cells requires intricate processes and sophisticated equipment. This includes machinery for electrode preparation, cell assembly, and testing. Each of these stages significantly influences the efficiency, safety, and overall performance of the final product. As technology advances, manufacturers are focusing on creating more automated and precise equipment that can enhance production efficiency while maintaining high quality.

Exporters of prismatic cell manufacturing equipment are increasingly catering to the needs of the global market. They provide a range of machinery adapted to various production scales, from large-scale industrial operations to smaller, specialized facilities. The ability to produce high-efficiency equipment that can handle evolving technologies—such as solid-state batteries—will be a key differentiator in the competitive landscape of equipment manufacturers.

Global Market Dynamics

Several key players dominate the prismatic cell manufacturing equipment export market, primarily located in regions like Asia, Europe, and North America. Countries such as China, South Korea, and Japan are leading producers of not only prismatic cells but also the requisite manufacturing technologies. The ongoing shift towards electric mobility and renewable energy storage solutions is driving significant growth in these regions.

prismatic cell manufacturing equipment exporters

China, in particular, has established itself as a powerhouse in battery technology and equipment manufacturing. With substantial investments from the government and private sector, companies are rapidly scaling up their production capabilities. The Belt and Road Initiative has further enhanced the country’s position by facilitating trade relationships with emerging markets looking to invest in energy storage solutions.

Technological Innovations

The landscape of prismatic cell manufacturing is continuously evolving, driven by innovations in battery chemistry and production processes. For example, advancements in automation and artificial intelligence are streamlining production lines and minimizing human error. Additionally, companies are focusing on improving the recyclability of batteries, addressing environmental concerns, and complying with stricter regulations.

Exporters are increasingly integrating smart technologies into their equipment to provide predictive maintenance capabilities, real-time monitoring, and advanced analytics. These features not only enhance operational efficiency but also ensure higher throughput and reduced costs.

Challenges and Opportunities

Despite the robust growth, several challenges persist in the prismatic cell manufacturing sector. Supply chain disruption, fluctuating raw material prices, and environmental regulations can significantly impact the production costs and timelines for manufacturers and exporters. However, these challenges also present opportunities for innovation. Developing alternative materials or recycling technologies can mitigate the supply chain risks associated with critical components like lithium and cobalt.

Moreover, as government policies worldwide push for greener technologies, exporters of prismatic cell manufacturing equipment are well-positioned to benefit from increasing investments in battery production and renewables.

Conclusion

The prismatic cell manufacturing equipment export sector is poised for substantial growth amid the accelerating global transition to sustainable energy. With the increasing demand for energy storage solutions, coupled with advancements in technology and manufacturing processes, exporters in this field play a critical role in shaping the future of energy consumption. As the global community seeks to address energy demands sustainably, the importance of innovative manufacturing equipment for prismatic cells will continue to rise, paving the way for a cleaner, more efficient energy landscape.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025