FMEA Analysis for Rear Door Rubber Seal Quality Improvement and Export Strategies

Understanding the Importance of FMEA in Rear Door Rubber Seal Exportation

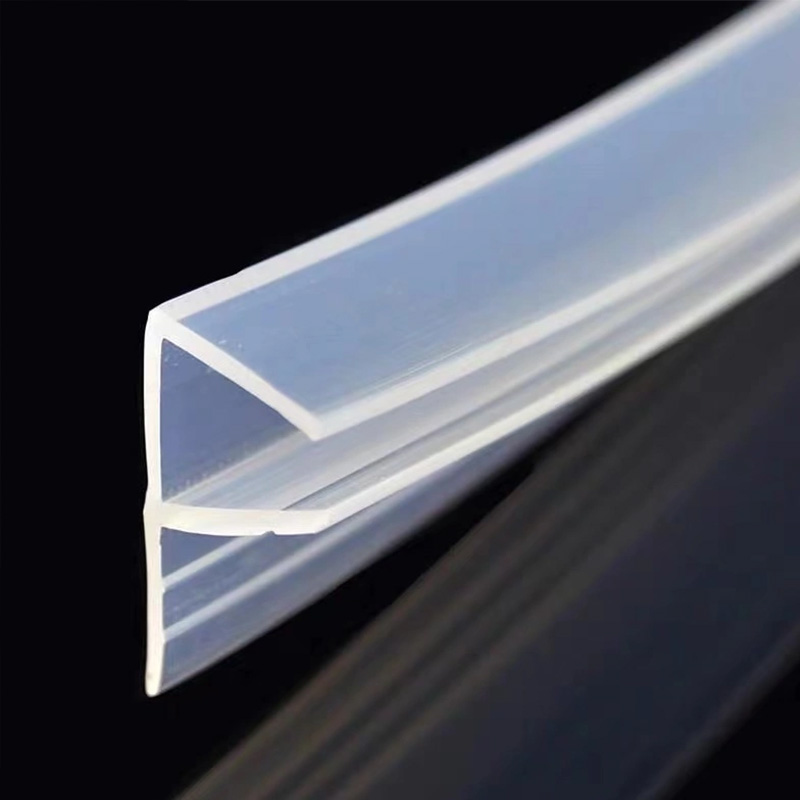

In the automotive industry, ensuring the quality and reliability of components is crucial for maintaining safety and performance. One key component that often goes unnoticed is the rear door rubber seal. This seemingly simple part serves a significant function in preventing water ingress, noise, and air leaks, thereby contributing to overall passenger comfort and vehicle integrity. As the demand for automotive components continues to rise, especially for exports, the process of Failure Mode and Effects Analysis (FMEA) becomes increasingly essential for manufacturers and exporters of rear door rubber seals.

Understanding the Importance of FMEA in Rear Door Rubber Seal Exportation

The first step in conducting an FMEA for rear door rubber seals involves assembling a cross-functional team of experts from various fields, including design, manufacturing, quality control, and logistics. This team collaborates to brainstorm potential failure modes, such as material degradation, improper fit, or adhesion failures. Each identified failure mode is then analyzed for its severity, occurrence, and detection rating, allowing the team to calculate a Risk Priority Number (RPN) for each issue.

rear door rubber seal fmea exporter

A critical aspect of FMEA is addressing the potential impact of these failures on the customer and the vehicle's overall performance. For instance, a compromised rear door seal may lead to water leaks, which could damage internal components or promote rust formation. Additionally, inadequate sealing could result in wind noise, disrupting the driving comfort. Therefore, addressing these failure modes proactively is paramount for enhancing customer satisfaction and brand reputation.

Once the potential failure modes are identified and assessed, the next step involves developing action plans to mitigate these risks. This may include changes to material selection, enhancing manufacturing processes, or redesigning the seal for a better fit. For instance, opting for high-quality rubber compounds that have better resistance to UV exposure and extreme temperatures can significantly extend the lifespan of the seals. Regular training of production staff and inspection protocols are also crucial in ensuring that the seals are consistently manufactured to the highest standards.

Furthermore, proper documentation and continuous monitoring play a vital role in the FMEA process. Exporters of rear door rubber seals must maintain thorough records of failure modes, RPN calculations, and actions taken. These documents are not only beneficial for internal audits but also essential for compliance with international regulatory standards. As automotive regulations become more stringent across different markets, having a robust FMEA process can enhance market entry and support smooth export operations.

In conclusion, as the global automotive market expands, the role of FMEA in the exportation of rear door rubber seals cannot be overstated. It provides manufacturers with a framework to identify potential issues proactively, implement corrective actions, and assure quality. Ultimately, this systematic approach not only enhances product reliability but also fosters customer trust and loyalty, essential components for success in the competitive automotive industry. By prioritizing FMEA in their processes, exporters of rear door rubber seals can play a pivotal role in advancing vehicle safety and performance.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025