How to Remove Rubber Door Seals in FRS Production Facilities

Removing Rubber Door Seals in Factories A Comprehensive Guide

The manufacturing landscape is evolving rapidly, with industries constantly seeking ways to enhance efficiency, safety, and sustainability. One often-overlooked component in this quest for optimization is the rubber door seal. While these seals play a crucial role in maintaining environmental control within a factory by reducing drafts, noise, and humidity, there are specific scenarios where their removal may be necessary. This article will explore the process, reasons, and implications of removing rubber door seals in factories.

Understanding Rubber Door Seals

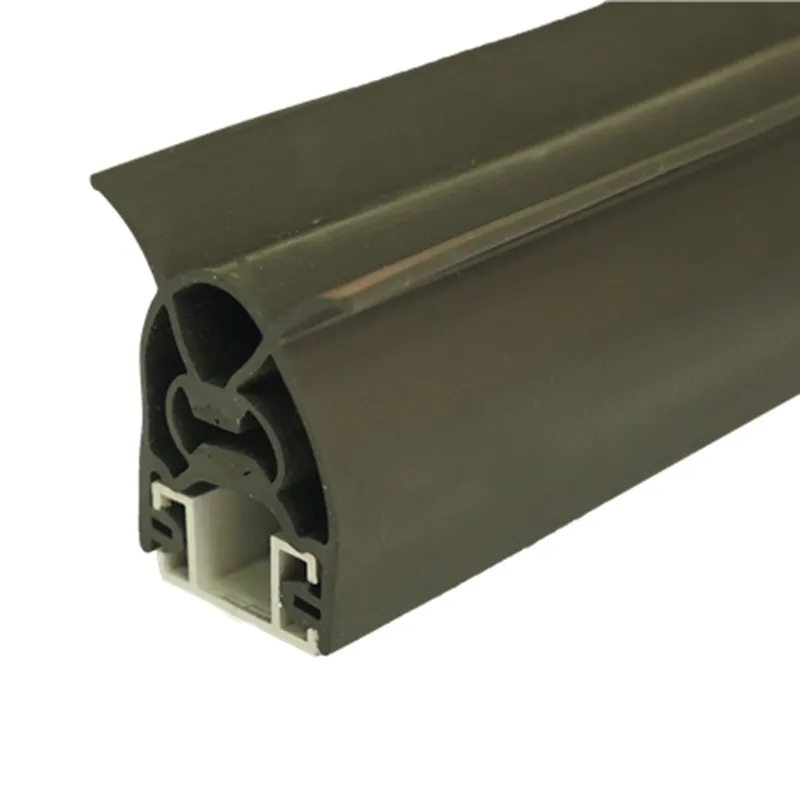

Rubber door seals are essential components that provide insulation and ensure the operational integrity of doors in industrial settings. Typically made from durable materials, these seals prevent air leakage, protect against dust and pollutants, and offer sound dampening. They are found in various types of doors, including fire doors, freezer doors, and general access points throughout the factory.

Reasons for Removal

1. Maintenance and Repairs Over time, rubber seals can wear out, crack, or lose their effectiveness. Regular inspections might reveal the need for seal replacement or removal for extensive door repairs that cannot be performed with the seal in place.

2. Upgrade to New Technology As factories modernize, they might implement new door systems that are more efficient or suited to their production needs. These modern systems may not require traditional rubber seals or may have integrated sealing technologies that outperform rubber.

3. Change in Use A shift in factory operations might necessitate different door functionalities. For example, if a storage area is converted to a high-traffic room, the old seals may hinder operator efficiency, requiring their removal.

4. Environmental Considerations In some cases, factories are striving toward greener operations. This can include the removal of rubber seals if they are not made from recyclable materials or if more sustainable options are available.

The Removal Process

removing rubber door seal frs factories

Removing rubber door seals is not a simple task, but with the right approach, it can be performed effectively

1. Preparation Before starting the removal process, ensure that the area is safe and secure. Clear any obstacles around the door to provide ample space for work. Use appropriate personal protective equipment (PPE), such as gloves and goggles.

2. Identify the Attachment Method Rubber seals can be attached via adhesives, mechanical fasteners, or molded fittings. Inspect how the seal is fixed to the door frame.

3. Careful Removal If the seal is glued on, gently pry it away using a flat tool to avoid damaging the door or frame. For mechanically fastened seals, remove screws or bolts carefully. Take your time to ensure you do not break or splinter the door frame.

4. Clean the Surface Once the seal is removed, clean the door frame thoroughly to remove residue, dirt, or old adhesive. A clean surface is essential for fitting a new seal or door system.

5. Inspection Check the door for any signs of damage that may have been concealed by the rubber seal. Address any issues before installing new seals or door hardware.

Implications of Removal

Removing rubber door seals can lead to immediate changes in the factory environment. While it may facilitate maintenance or upgrades, it can also impact temperature regulation, air quality, and noise levels. Therefore, it is essential to assess the implications thoroughly and implement alternative sealing solutions if necessary.

Conclusion

The removal of rubber door seals in factories is a nuanced task that should be approached with care and planning. Whether prompted by maintenance, technological updates, or operational changes, understanding the process and implications is crucial for maintaining efficiency and safety in a manufacturing environment. By prioritizing these considerations, factories can navigate the complexities of seal removal and continue their journey towards operational excellence.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025