rolling press machine for cylindrical battery production factories

The Role of Rolling Press Machines in Cylindrical Battery Production

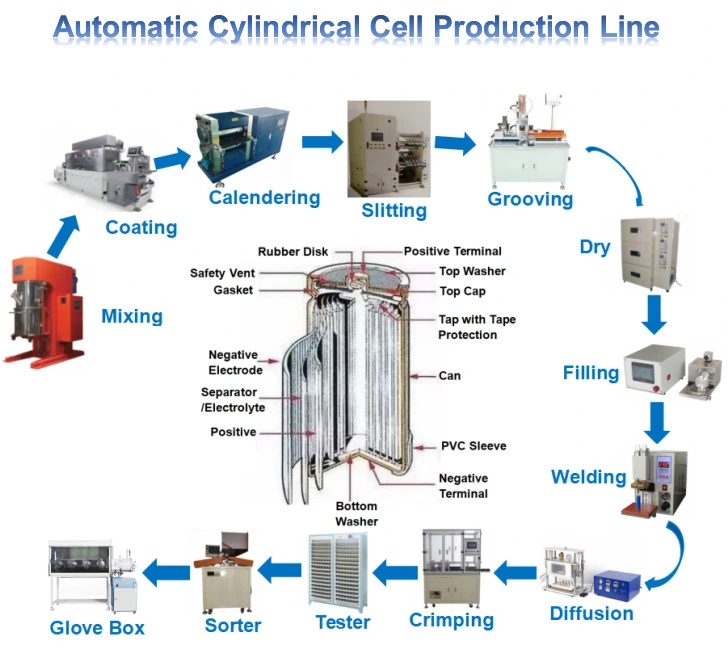

In the era of renewable energy and electric mobility, the demand for cylindrical batteries has surged significantly. These batteries power everything from electric vehicles to portable electronics. At the heart of the production process for these cylindrical batteries lies a crucial piece of equipment the rolling press machine. This machine plays an integral role in shaping the electrodes that ultimately ensure the efficiency and performance of the battery.

Understanding the Rolling Press Machine

A rolling press machine is designed to compress and shape materials through a series of rollers. In the context of cylindrical battery production, it is primarily used to process the active materials that make up the battery electrodes, such as lithium, nickel, cobalt, and manganese. The rolling process helps to achieve uniform thickness and density, which are critical for optimal battery performance.

The operation of the rolling press involves several key steps. Initially, the active material, which is typically in a paste or slurry form, is deposited onto a substrate, usually a metal foil. As the rolls move closer together, the material is pressed and elongated, creating a thin film of uniform thickness. This not only enhances the conductivity of the material but also ensures that the active materials are properly layered, providing the necessary electrochemical properties.

Importance in Battery Production

The quality of the rolling process directly impacts the performance of the final battery. Uniform electrode thickness leads to consistent energy output and improved cycling stability, while any discrepancies can result in inefficient energy storage and a shorter lifespan for the battery. Therefore, manufacturers invest heavily in rolling press technology to ensure that they meet stringent industry standards.

rolling press machine for cylindrical battery production factories

Additionally, with the rise of high-capacity batteries designed for electric vehicles and grid storage, the demand for advanced rolling press machines has increased. These machines are engineered to handle the high pressures and specific tolerances required for producing next-generation battery electrodes. Modern rolling presses often come equipped with sensors that monitor the thickness and pressure in real-time, providing data that can be used to optimize the production process.

Advancements in Rolling Press Technology

Recent advancements in rolling press technology have further enhanced the manufacturing process for cylindrical batteries. Innovations such as automatic feedback control systems, enhanced cooling capabilities, and the use of advanced materials for roll construction have improved efficiency and reduced energy consumption. These improvements not only lower production costs but also contribute to more sustainable manufacturing practices, which is crucial in today’s environmentally-conscious market.

Moreover, manufacturers are exploring the integration of artificial intelligence and machine learning to predict and optimize the rolling process. By analyzing data from previous production runs, these intelligent systems can adjust parameters in real time, enhancing output quality and reducing waste.

Conclusion

As the cylindrical battery market continues to expand, the importance of rolling press machines cannot be overstated. These machines are fundamental to producing high-quality electrodes that meet the increasing demands for battery performance and reliability. With ongoing advancements in technology, the future of rolling press machinery holds great promise, paving the way for more efficient and sustainable battery production processes. This, in turn, supports the global shift towards cleaner energy solutions and the electrification of transportation, making rolling press machines vital players in the green energy revolution.

In summary, the rolling press machine stands as a cornerstone of cylindrical battery manufacturing, embodying the convergence of engineering excellence and technological innovation in a rapidly evolving industry.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025