Rolling Press Machines for Efficient Production in Cylindrical Battery Manufacturing Industries

The Role of Rolling Press Machines in Cylindrical Battery Production

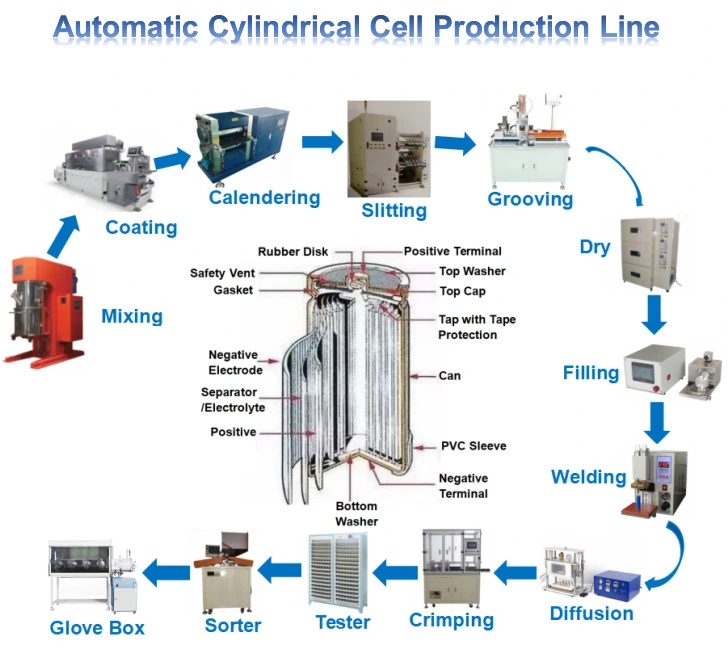

In the rapidly advancing world of technology, the demand for efficient and high-capacity battery solutions is ever-increasing. Among the various types of batteries, cylindrical batteries stand out due to their robustness, energy density, and versatility in applications ranging from consumer electronics to electric vehicles. One crucial piece of equipment in the production of cylindrical batteries is the rolling press machine. This machine plays a pivotal role in ensuring the quality and efficiency of battery manufacturing processes.

Rolling press machines are specifically designed to compress and roll components used in cylindrical batteries, such as electrodes and separators. The primary goal of these machines is to optimize the density of the materials, which is vital for enhancing the overall performance of the battery. By using rolling press machines, manufacturers can achieve uniform thickness and consistent density, leading to better energy storage capacity and improved battery life.

The process begins with the preparation of electrode materials, typically composed of active substances like lithium, cobalt, and nickel. These materials are mixed with binders and conductive additives to form a slurry that is then coated onto a suitable substrate, usually aluminum or copper foil. Once the electrodes are prepared and dried, the rolling press machine comes into play. It applies pressure and rolls the electrode sheets, reducing their thickness while increasing their density.

rolling press machine for cylindrical battery production factories

One notable advantage of using rolling press machines in cylindrical battery production is the ability to scale operations while maintaining high-quality standards. Automated rolling systems can handle large volumes of material and maintain consistent output, reducing labor costs and minimizing human error. Furthermore, advancements in technology have led to the development of precision rolling press machines that provide higher control over parameters such as pressure and speed, ensuring optimal product quality.

Another key aspect of rolling press machines is their ability to enhance the thermal and electrical conductivity of the electrodes. By compressing the electrode materials, the contact points between the particles are improved, facilitating better electron flow and heat dissipation. This is crucial for the performance of batteries, particularly in high-drain applications like electric vehicles, where efficient power delivery is paramount.

Moreover, the integration of rolling press machines in production lines allows for better environmental sustainability. By optimizing material usage and reducing waste during the manufacturing process, these machines contribute to a lower ecological footprint. The increased efficiency not only saves materials but also reduces energy consumption, aligning with global efforts to promote greener production practices.

In conclusion, rolling press machines are indispensable in the production of cylindrical batteries, driving advancements in performance and efficiency. As the demand for batteries continues to rise, particularly with the growth of electric vehicles and renewable energy storage systems, the role of these machines will only become more critical. By ensuring high-density, high-quality electrode production, rolling press machines are paving the way for the next generation of battery technology. With ongoing innovations and a focus on sustainability, the future of cylindrical battery production looks promising, and rolling press machines will undoubtedly play a significant part in this evolution.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025