Supplier of Rolling Press Machines for Cylindrical Battery Manufacturing Solutions

The Role of Rolling Press Machines in Cylindrical Battery Production An Overview of Suppliers

In the fast-evolving world of battery technology, cylindrical batteries have gained significant attention due to their efficiency, energy density, and adaptability in various applications ranging from electric vehicles (EVs) to portable electronics. As the demand for these batteries increases, manufacturers are continually seeking advanced machinery that enhances production quality and efficiency. One such essential piece of equipment is the rolling press machine, which plays a pivotal role in the manufacturing process of cylindrical batteries.

Functionality of Rolling Press Machines

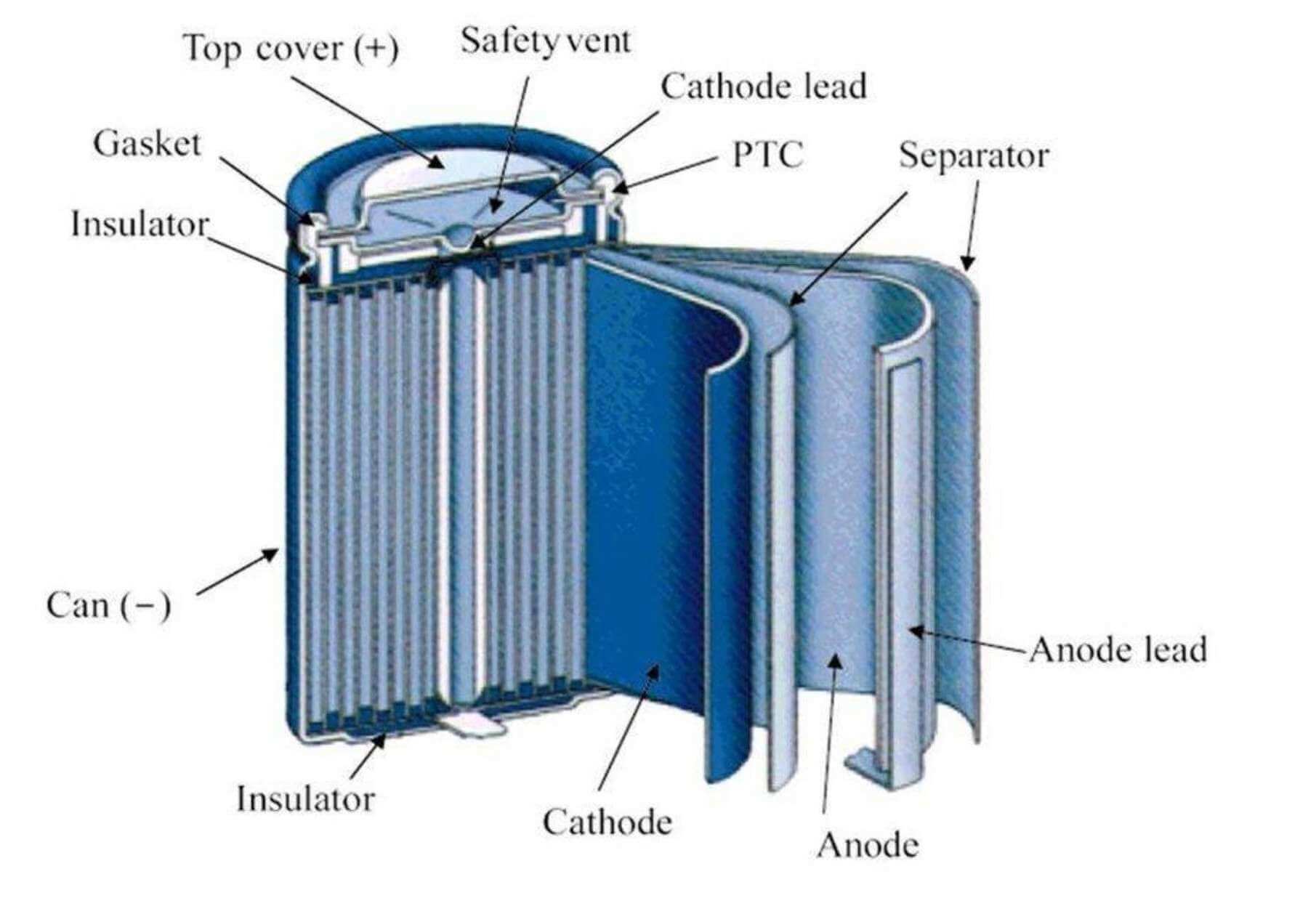

Rolling press machines are designed to compact and shape materials, making them integral to the production process of cylindrical batteries. These machines excel in compressing active materials, such as cathodes and anodes, into uniform sheets or electrodes. The precision and consistent pressure applied by rolling presses ensure that the materials achieve the desired density and thickness, which are critical for optimizing battery performance and longevity.

The process begins with the mixing of active materials with binders and solvents. Once the slurry is prepared, it is fed into the rolling press machine. Here, the material undergoes rolling between two heavy rollers that apply significant pressure, thereby removing air pockets and creating a uniform electrode. This is crucial because inconsistencies in thickness or density can lead to performance issues in the finished battery. The compacted electrodes are then cut into the desired shapes and sizes to be assembled into cylindrical cells.

Importance in Battery Production

The efficiency of rolling press machines directly impacts the quality and output of cylindrical battery production. With advancements in technology, modern rolling presses are equipped with features such as temperature control, automated thickness adjustment, and real-time monitoring systems, enhancing the manufacturing process. These innovations help manufacturers increase their production rates while maintaining quality standards.

Moreover, the scalability of rolling press machines is a significant advantage. As demand for cylindrical batteries grows, manufacturers can adjust their production capacities by utilizing these machines in a variety of configurations. From small-scale operations to large industrial setups, rolling presses can accommodate varying production volumes while ensuring that each battery meets safety and performance criteria.

Choosing the Right Supplier

rolling press machine for cylindrical battery production supplier

Selecting a reliable supplier for rolling press machines is crucial for battery manufacturers. When searching for suppliers, companies should consider several factors

1. Experience and Reputation Established suppliers with a history in the battery manufacturing industry often have the expertise and technical know-how to provide high-quality machinery.

2. Customization Options Every production line is unique. Suppliers that offer customizable solutions can help manufacturers optimize their processes to meet specific requirements.

3. Support and Service Technical support and maintenance services are vital to ensure that machines operate at peak efficiency. Reliable suppliers often provide extensive after-sales support.

4. Technology and Innovation Suppliers that invest in research and development tend to offer the latest technologies, which can significantly impact production efficiency and product quality.

5. Cost Considerations While it is essential to keep costs in check, choosing a supplier based solely on price might lead to compromises in quality and support. A balance between cost and value is essential.

Conclusion

In the quest for efficient cylindrical battery production, rolling press machines stand out as indispensable tools. They enhance the manufacturing process by ensuring uniformity and quality in electrode production, which directly influences the performance of the finished batteries. As the electric vehicle and renewable energy markets continue to expand, the role of these machines will only become more critical. By choosing the right supplier, manufacturers can significantly improve their battery production capabilities, ensuring they stay competitive in an ever-evolving market. As technology progresses, the future of cylindrical battery manufacturing will likely rely heavily on these advanced machines, paving the way for innovations in energy storage solutions.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025