Top Manufacturers of High-Quality Rubber Car Door Seals for Optimal Performance

Understanding the Importance of Rubber Car Door Seal Manufacturers

Rubber car door seals might seem like a small component of a vehicle, but they play a critical role in the overall performance and comfort of cars. The manufacturers of these seals are essential players in the automotive industry, providing solutions that enhance vehicle functionality and user experience. This article explores the significance of rubber car door seal manufacturers, their manufacturing processes, and the benefits of quality seals in automobiles.

The Role of Rubber Car Door Seals

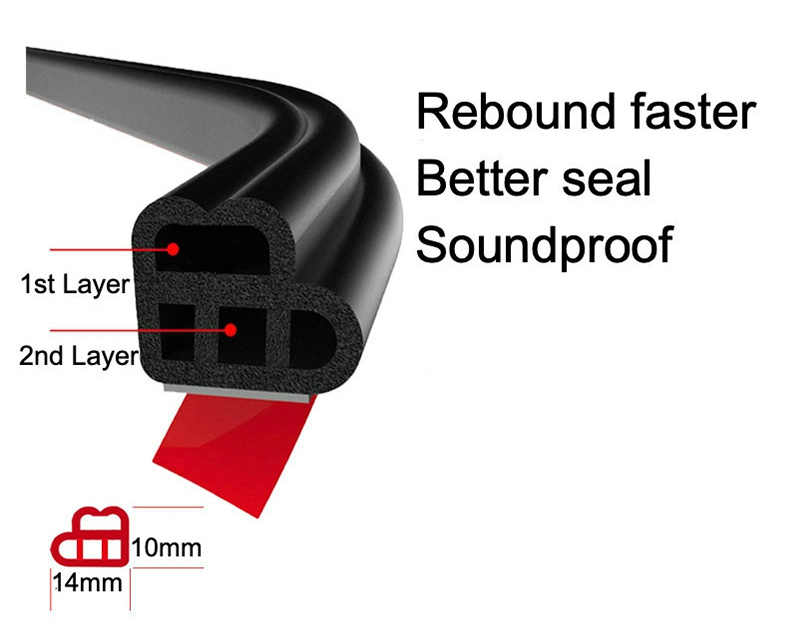

Rubber door seals are designed to create a tight seal between the car door and the body of the vehicle. Their primary functions include preventing water leakage, reducing road noise, and maintaining the car's internal climate control. A good seal ensures that rainwater does not leak into the interior, which can lead to mold, rust, and other forms of damage over time. Additionally, they help to keep external noises, such as wind and traffic sounds, from disrupting the driving experience, contributing to a more comfortable ride.

Manufacturing Processes

The manufacturing of rubber car door seals involves several stages, including material selection, molding, and quality control. Manufacturers often use high-quality materials such as EPDM (Ethylene Propylene Diene Monomer) rubber due to its durability and resistance to temperature fluctuations, UV rays, and ozone.

1. Material Selection Choosing the right type of rubber is crucial. Manufacturers must assess the specific requirements of different vehicle models and select materials that comply with safety standards and performance expectations.

rubber car door seal manufacturers

2. Molding The rubber is shaped into specific profiles that fit the design of various car models. Advanced technologies such as extrusion and injection molding are often employed to ensure precision in manufacturing. This process demands skilled technicians who understand the intricacies of rubber processing.

3. Quality Control After production, the seals undergo rigorous testing to ensure they meet quality standards. This can include pressure tests, temperature resistance tests, and aging tests to simulate long-term usage. Quality control is vital to ensure that only the best products make it to the market, minimizing the risk of defects.

Benefits of High-Quality Rubber Seals

Investing in high-quality rubber car door seals provides numerous advantages. Firstly, they enhance vehicle safety by ensuring a proper seal that keeps out water and dirt, protecting the car's internal components. Secondly, they improve energy efficiency by allowing heating and cooling systems to work effectively, which can lead to lower fuel consumption.

Moreover, high-quality seals contribute to the overall aesthetics of a vehicle. They fit seamlessly, giving the car a polished look and feel. Additionally, premium seals often come with warranties, reflecting the manufacturer's confidence in their product and providing reassurance to consumers.

Conclusion

In conclusion, rubber car door seal manufacturers are pivotal in enhancing the safety, comfort, and efficiency of modern vehicles. Their commitment to quality and innovation ensures that cars are equipped with seals that not only perform well but also stand the test of time. As the automotive industry continues to evolve, these manufacturers will play an increasingly important role in shaping the future of vehicle design and functionality. By understanding the significance of these components, consumers can make informed choices and appreciate the engineering that goes into every aspect of their vehicles.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025