Exporters of Quality Rubber Door Seals for Enhanced Insulation and Durability

The Global Landscape of Rubber In-Door Seal Exporters

In the ever-evolving world of industrial materials, rubber in-door seals play a crucial role across various applications, from automotive to construction. These seals provide essential benefits they function as barriers against dust, water, and noise, enhancing the longevity of vehicles and ensuring the structural integrity of buildings. As the demand for high-quality rubber door seals continues to rise, an impressive network of exporters has emerged worldwide, seeking to meet the needs of diverse markets.

Understanding Rubber In-Door Seals

Rubber in-door seals are specifically designed to fit around door frames, providing a tight seal that prevents the penetration of air and water. Made from thermoplastic elastomers (TPE), neoprene, EPDM (ethylene propylene diene monomer), or silicone rubber, these seals are renowned for their durability, flexibility, and resistance to harsh weather conditions. Their applications span numerous industries, including automotive manufacturing, residential construction, and even aerospace engineering.

The Importance of Quality Standards

Quality is paramount in the production of rubber in-door seals, as these components are critical in ensuring safety and efficiency in various applications. Exporters must adhere to stringent quality standards set by international bodies such as ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials). Compliance with these standards assures clients that the products they receive will perform effectively under demanding conditions.

Major Exporter Regions

The global market for rubber in-door seals is predominantly characterized by key exporter regions. Asia, particularly China and India, has emerged as a manufacturing powerhouse, significantly contributing to the supply of rubber door seals. These countries benefit from low labor costs, a robust manufacturing infrastructure, and an abundance of raw materials. As a result, they can produce high volumes of competitive products, catering to both local and international markets.

rubber in-door seal exporters

Europe follows closely behind, with countries such as Germany and Italy known for their focus on advanced materials and high-precision engineering. European exporters often emphasize innovation and custom solutions, tapping into niche markets that require specialized seals for environmentally sensitive applications.

North America, particularly the United States and Mexico, also plays a vital role in the rubber in-door seal export market. With a strong automotive industry and stringent regulatory requirements, North American exporters prioritize quality and sustainability, focusing on eco-friendly materials and manufacturing processes.

Trends Shaping the Market

Several trends are currently shaping the rubber in-door seal export market. First, the increasing emphasis on energy efficiency has led to a surge in demand for quality seals that can improve insulation in buildings and vehicles. As governments worldwide enforce stricter regulations aimed at reducing energy consumption, the demand for reliable rubber seals will continue to grow.

Furthermore, the shift toward electric vehicles (EVs) is influencing the design and production of rubber in-door seals. These vehicles require unique sealing solutions to address their specific performance and durability needs. As the EV market expands, exporters that adapt quickly to these trends will likely enjoy significant competitive advantages.

Conclusion

The rubber in-door seal export market represents a dynamic and essential segment of global trade. With a diverse range of exporters from varying regions and a relentless demand for quality and innovation, the future of this market looks promising. Companies that prioritize quality standards, sustainability, and market adaptability are well-positioned to thrive in this competitive landscape, ensuring that they meet the ever-growing needs of consumers around the world. As technology advances and consumer preferences evolve, the role of rubber in-door seals will undoubtedly continue to expand, solidifying their importance in countless applications.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

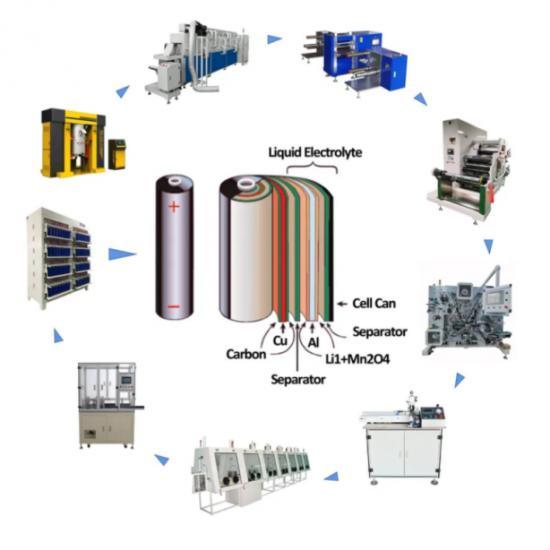

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025