Manufacturer of Rubber Seals for Door Closing Solutions

The Importance of Rubber Seals in Door Manufacturing

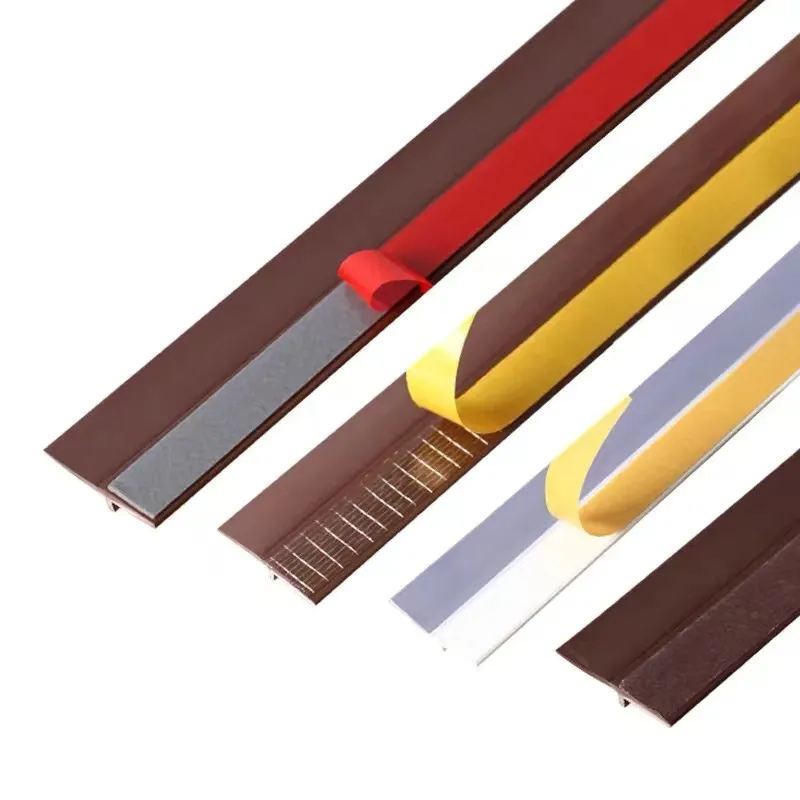

In the world of manufacturing, precision and quality are paramount, especially when it comes to components that ensure safety and functionality. One such key element is the rubber piece used to seal doors. These seals play a critical role in a variety of applications, from residential homes to commercial buildings and industrial environments.

Rubber seals are primarily designed to fill the gap between a door and its frame, providing several essential functions. Firstly, these seals improve energy efficiency by preventing air leaks. In climates with extreme temperatures, such as hot summers or cold winters, maintaining a stable indoor environment is crucial. A properly sealed door can minimize heating and cooling costs, enabling homeowners and businesses to save significantly on energy bills.

Moreover, rubber seals contribute to sound insulation. In urban settings where noise pollution is prevalent, sealing doors with high-quality rubber can dramatically reduce the transfer of sound between spaces. Whether it's the hustle and bustle of city life or the clamor of machinery in industrial units, effective soundproofing fosters a more serene and productive environment.

Another vital aspect of rubber seals is their ability to prevent water intrusion. In areas prone to heavy rainfall or flooding, a well-sealed door acts as a barrier against moisture, protecting the interior spaces from water damage. This is especially important in basements and ground-level entrances where water leaks can lead to mold growth and structural damage over time.

rubber piece to seal door manufacturer

Durability is a key characteristic of rubber seals. Quality manufacturers use materials that withstand environmental factors like UV exposure, temperature fluctuations, and physical wear and tear. This durability ensures that the seals maintain their integrity and effectiveness over time, reducing the need for frequent replacements and thereby saving both time and money.

When selecting a rubber seal for a door, manufacturers have various options to consider. Different types of rubbers, such as EPDM (ethylene propylene diene monomer), Nitrile, and Neoprene, offer unique benefits tailored to specific environments. For example, EPDM is known for its excellent weather resistance, making it a popular choice for outdoor applications. In contrast, Nitrile is often favored in industrial settings due to its oil and chemical resistance.

Moreover, the manufacturing process of these rubber seals has seen significant advancements. Custom molding techniques allow for the production of seals tailored to the unique specifications of different door designs, enhancing their performance. Moreover, manufacturers are increasingly focused on sustainable practices, utilizing eco-friendly materials and methods to produce rubber seals that are both effective and environmentally responsible.

In conclusion, the rubber piece used to seal doors is an indispensable component in the doorway systems of modern construction. Its benefits extend beyond simple gap filling; it enhances energy efficiency, sound insulation, and waterproofing, all while ensuring durability and longevity. For anyone involved in the door manufacturing industry, understanding the critical role of rubber seals can lead to informed decisions that ultimately elevate product quality and customer satisfaction.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025