rubber seal for window door manufacturers

The Importance of Rubber Seals for Window and Door Manufacturers

In the realm of construction and manufacturing, ensuring the durability, efficiency, and effectiveness of products is paramount. One critical component that plays a significant role in the overall performance of windows and doors is the rubber seal. This article explores the importance of rubber seals, their manufacturing process, and how they contribute to enhancing the functionality of windows and doors.

Understanding Rubber Seals

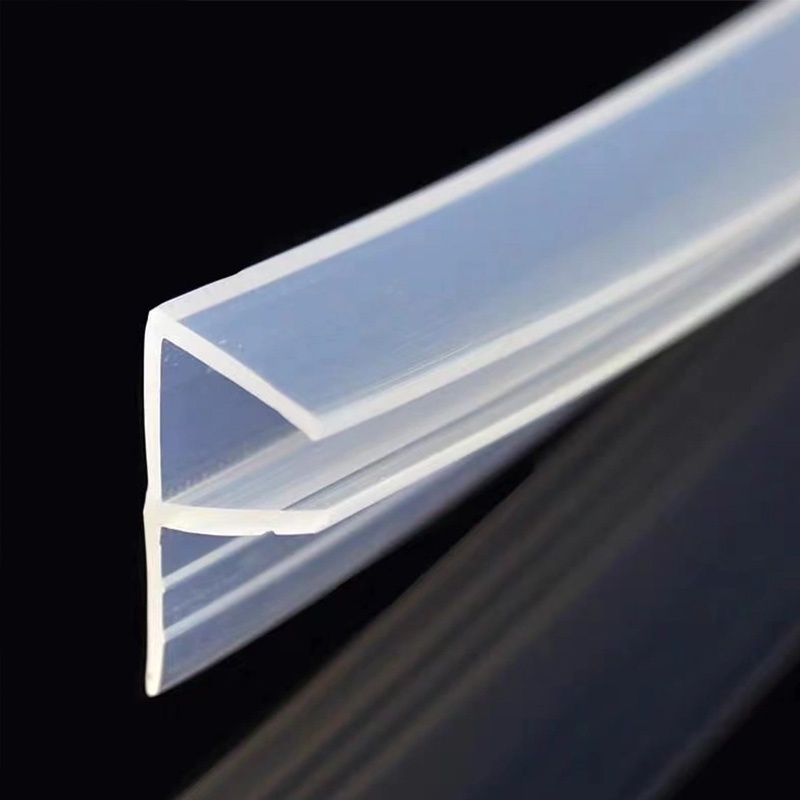

Rubber seals, also known as weatherstripping or gaskets, are essential elements used to create airtight and watertight barriers around windows and doors. These seals prevent air and water infiltration, which can lead to energy loss, increased utility bills, and potential damage to the building structure. They come in various shapes, sizes, and materials, with rubber being the most widely used due to its flexibility, durability, and resistance to environmental factors.

Key Benefits of Rubber Seals

1. Energy Efficiency One of the primary benefits of using rubber seals in windows and doors is energy efficiency. By preventing drafts and air leaks, these seals minimize the workload on heating and cooling systems, leading to lower energy consumption and reduced costs. This is especially crucial in regions with extreme weather conditions, where maintaining a stable indoor temperature can be challenging.

2. Moisture Control Rubber seals act as a barrier against moisture, preventing water from seeping into the premises. This protection is vital for maintaining the integrity of the building and preventing mold growth, wood rot, and damage to the interiors. In coastal areas or places with heavy rainfall, having robust rubber seals can make a significant difference.

3. Noise Reduction Another advantage of rubber seals is their ability to reduce noise infiltration. With urbanization and increasing noise pollution, homeowners and businesses are looking for ways to create quieter environments. Rubber seals can significantly dampen external noise, contributing to a more peaceful indoor atmosphere.

4. Enhanced Security Quality rubber seals provide an additional layer of security for windows and doors. A well-sealed window or door is harder to force open, deterring potential intruders. Additionally, rubber seals help maintain the structural integrity of the frame, which can be beneficial in preventing break-ins.

5. Longevity and Durability Rubber is inherently resilient and can withstand various environmental conditions. When used in window and door manufacturing, rubber seals are designed to resist aging, UV damage, and extreme temperatures. This durability ensures that the seals maintain their performance over time, reducing the need for frequent replacements and maintenance.

rubber seal for window door manufacturers

Manufacturing Process of Rubber Seals

The manufacturing of rubber seals involves a series of steps to ensure quality and precision. It typically begins with the selection of high-quality rubber materials suitable for the intended application. Manufacturers may use natural rubber, synthetic rubber, or a combination, depending on the desired properties.

1. Mixing Rubber compounds are created by mixing raw rubber with additives such as fillers, accelerators, and UV stabilizers. This mixture is crucial for enhancing the physical properties of the rubber, including flexibility, strength, and resistance to environmental factors.

2. Molding The mixed rubber is then subjected to a molding process where it is shaped into the desired profile for seals. Techniques like compression molding and extrusion are commonly used to achieve the specific designs needed for different window and door types.

3. Curing After molding, the rubber seals undergo a curing process, also known as vulcanization. This chemical reaction transforms the rubber into a durable and resilient material, solidifying its shape and enhancing its properties.

4. Quality Control A critical step in manufacturing is the quality control process, where seals are rigorously tested for integrity, flexibility, and resistance to wear and tear. This ensures that only high-quality products reach the market.

5. Distribution Finally, the rubber seals are packaged and distributed to window and door manufacturers, contractors, and retailers.

Conclusion

In conclusion, rubber seals play a vital role in the manufacturing of windows and doors, providing benefits that enhance the overall performance and longevity of these essential architectural elements. As manufacturers continue to innovate and improve the materials and techniques used in seal production, the future of energy-efficient and sustainable building practices looks promising. For window and door manufacturers, investing in high-quality rubber seals is not just an option; it is a necessity for ensuring the comfort, safety, and satisfaction of their customers.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025