rubber sealing strip for doors and windows factory

The Importance of Rubber Sealing Strips for Doors and Windows A Focus on Manufacturing

In the modern world, energy efficiency and comfort are paramount considerations for both homeowners and businesses. One often overlooked component that significantly contributes to these two factors is the rubber sealing strip. Rubber sealing strips are essential for doors and windows, helping to prevent air leaks, reduce noise, and improve overall insulation. This article delves into the significance of rubber sealing strips, particularly in the context of manufacturing.

Understanding Rubber Sealing Strips

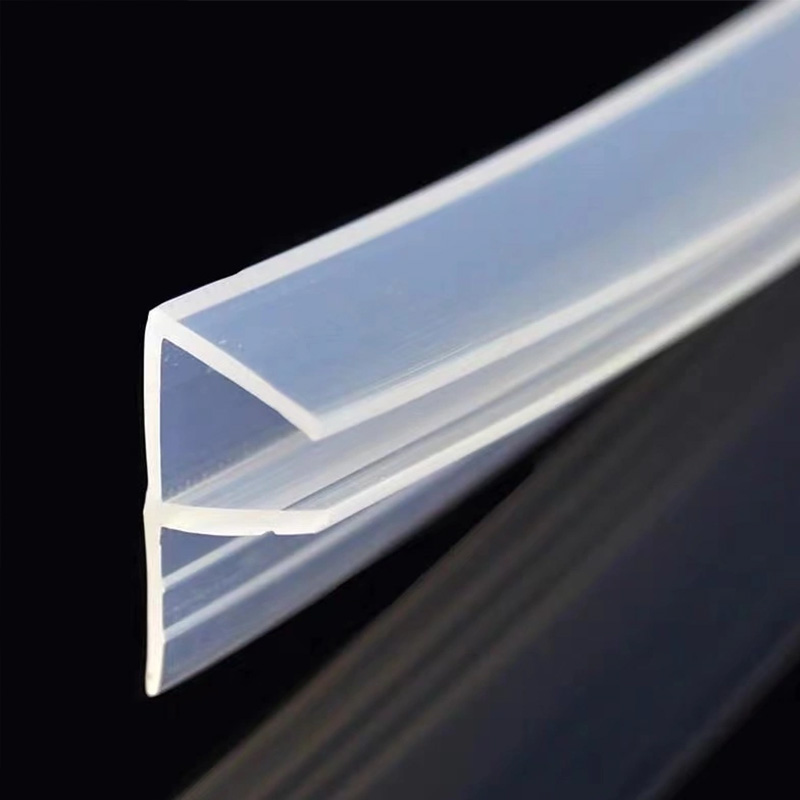

Rubber sealing strips are flexible strips made from various types of rubber, including EPDM (Ethylene Propylene Diene Monomer), silicone, and neoprene. These materials are chosen for their durability, flexibility, and resistance to temperature fluctuations, which make them ideal for sealing gaps around doors and windows. The primary function of these strips is to create an airtight and water-resistant seal when doors and windows are closed, preventing unwanted infiltration of external elements.

The Role of Sealing Strips in Energy Efficiency

One of the most critical roles of rubber sealing strips is enhancing energy efficiency in buildings. Poorly sealed doors and windows can lead to significant energy loss, resulting in increased heating and cooling costs. According to various studies, up to 30% of a building's energy can be lost due to air leaks. By installing high-quality rubber sealing strips, homeowners and businesses can reduce these leaks, leading to lower energy bills and a greener footprint.

Noise Reduction and Comfort

In addition to energy efficiency, rubber sealing strips provide excellent sound insulation. They help to minimize the intrusion of outside noise, which is particularly beneficial in urban areas where ambient noise levels can be high. By sealing gaps effectively, these strips contribute to a more peaceful indoor environment, enhancing the overall comfort of occupants.

Choosing the Right Rubber Sealing Strip

When selecting rubber sealing strips for doors and windows, manufacturers must consider several factors

1. Material Properties Different types of rubber offer various advantages. For instance, EPDM is known for its superior weather resistance, while silicone provides excellent flexibility and high-temperature resistance. Identifying the right material based on the specific application is crucial.

2. Size and Shape The dimensions of sealing strips must match the gaps they are intended to fill. Manufacturers offer a variety of sizes and profiles to accommodate different types of doors and windows.

rubber sealing strip for doors and windows factory

3. Durability High-quality rubber sealing strips are designed to withstand the elements, including UV exposure and extreme temperatures. Ensuring longevity is essential for sustained performance.

4. Installation Method Some sealing strips come with adhesive backing for easy installation, while others may require mechanical fastening. The choice of installation method can impact the ease of application and effectiveness.

The Manufacturing Process

The production of rubber sealing strips involves several stages, each vital for ensuring the final product's quality and functionality.

1. Material Sourcing Manufacturers must source high-grade rubber compounds that meet specific performance criteria.

2. Extrusion The rubber is usually processed through an extrusion machine, shaping it into the desired profile. This stage requires precision to ensure uniformity in thickness and width.

3. Curing The extruded rubber undergoes a curing process, where heat is applied to enhance its elasticity and strength. Proper curing is critical for the longevity of the sealing strips.

4. Quality Control After production, each batch of sealing strips goes through rigorous quality control checks. This includes testing for tensile strength, flexibility, and resistance to environmental factors.

5. Packaging and Distribution Once verified, the sealing strips are packaged appropriately for shipment to retailers or directly to consumers.

Conclusion

Rubber sealing strips play a critical role in improving energy efficiency, comfort, and sound insulation in buildings. Their manufacturing requires attention to detail and adherence to quality standards to ensure they perform effectively. As the world moves towards more energy-efficient solutions, the importance of high-quality rubber sealing strips for doors and windows will only continue to grow. Investing in these essential components can lead to long-term savings and a more comfortable living environment. Whether for residential or commercial applications, choosing the right rubber sealing strip is key to maximizing the benefits they offer.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025