rubber seal on fridge doors factory

The Importance of Rubber Seals on Fridge Doors A Look at Factory Manufacturing

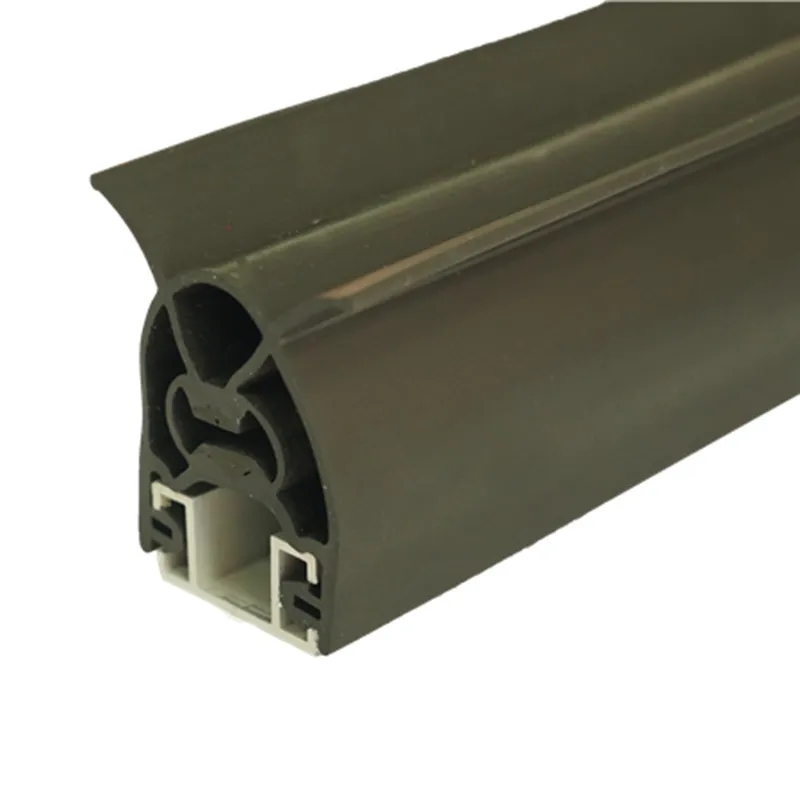

In the world of refrigeration, the significance of high-quality rubber seals on fridge doors cannot be overstated. These seemingly simple components play a crucial role in maintaining the efficiency, performance, and longevity of refrigerators. As we dive into the topic of rubber seals for fridge doors, we must explore their function, manufacturing process, and the impact they have on both consumers and manufacturers.

Understanding the Role of Rubber Seals

Rubber seals are the unsung heroes of refrigerator doors. Their primary function is to create an airtight seal between the fridge body and the door when closed. This seal is essential for several reasons

1. Energy Efficiency When the fridge door is closed, the rubber seal prevents warm air from entering the refrigerated space. This helps the refrigerator maintain its internal temperature without overworking the compressor, leading to significant energy savings for consumers.

2. Food Preservation A secure seal helps ensure that food remains fresh for longer periods. By keeping the cold air inside, rubber seals prevent temperature fluctuations that can lead to spoilage. This is particularly important for perishable items that require consistent refrigeration.

3. Noise Reduction The rubber seal also acts as a barrier to minimize noise caused by the operational mechanisms of the fridge. This makes for a quieter kitchen and more comfortable living environment.

4. Moisture Control A well-fitted rubber seal helps prevent moisture from entering the fridge, which can lead to mold growth and contamination of food. Proper sealing is essential for hygiene and food safety.

Manufacturing Rubber Seals in Factories

The production of rubber seals is a sophisticated process that requires precision and quality control

. Most manufacturers begin with high-quality rubber compounds that are specifically formulated to withstand extreme temperatures and wear. The manufacturing process typically involves several key stepsrubber seal on fridge doors factory

1. Compounding Various ingredients are mixed with raw rubber to achieve desired properties such as elasticity, durability, and resistance to temperature fluctuations. Additives may include carbon black, accelerators, and anti-oxidants.

2. Extrusion The compounded rubber is then extruded into long strips. This process shapes the rubber into the desired profile for fridge door seals, which is often a unique design to ensure a perfect fit.

3. Curing The extruded rubber undergoes a curing process, often referred to as vulcanization. This step involves heating the rubber to cross-link the molecules, which enhances its strength and elasticity.

4. Quality Control As with any manufacturing process, quality control is critical. Each batch of rubber seals undergoes rigorous testing to ensure they meet industry standards. Tests may include checking for flexibility, tensile strength, and thermal stability.

5. Packaging and Distribution Once the seals have passed inspection, they are cut to size, packaged, and distributed to manufacturers of refrigerators or sold directly to consumers for replacements.

Impact on Consumers and Manufacturers

For consumers, the reliability of rubber seals significantly impacts the performance of their refrigerators. A high-quality seal contributes to lower energy bills, better food preservation, and dependability of the appliance. Conversely, subpar seals may lead to increased energy costs and diminished appliance performance, ultimately affecting customer satisfaction.

For manufacturers, investing in high-quality rubber seals can enhance their brand reputation. It can reduce warranty claims related to refrigeration issues and lead to more positive reviews and customer loyalty. In an increasingly competitive market, the efficiency and reliability of appliances can be a key differentiator.

In conclusion, the role of rubber seals on fridge doors is a critical aspect of modern refrigeration. Their importance extends from energy efficiency to food safety, highlighting a need for high-quality manufacturing processes. As technology evolves, the rubber seal industry will likely continue to innovate, ensuring that refrigerators remain effective and reliable appliances in homes around the world.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025