rubber seals for rv slides manufacturers

Rubber Seals for RV Slides A Comprehensive Guide for Manufacturers

In recent years, the recreational vehicle (RV) industry has seen a steady rise in popularity, with more people looking to explore the great outdoors in the comfort of their mobile homes. As RV designs have evolved, so too have the components that make them functional and comfortable. One such critical component is the rubber seal used in RV slide-outs. This article provides an in-depth look at the significance of rubber seals for RV slides, the manufacturing processes involved, and key considerations for manufacturers.

Understanding RV Slides

RV slides are mechanisms that extend outward from the main structure of the vehicle, increasing the living space when parked. While the additional room is a significant advantage, it introduces potential issues regarding insulation, weatherproofing, and overall functionality. This is where rubber seals come into play, ensuring that slides operate smoothly while preventing water intrusion and air leakage.

The Role of Rubber Seals

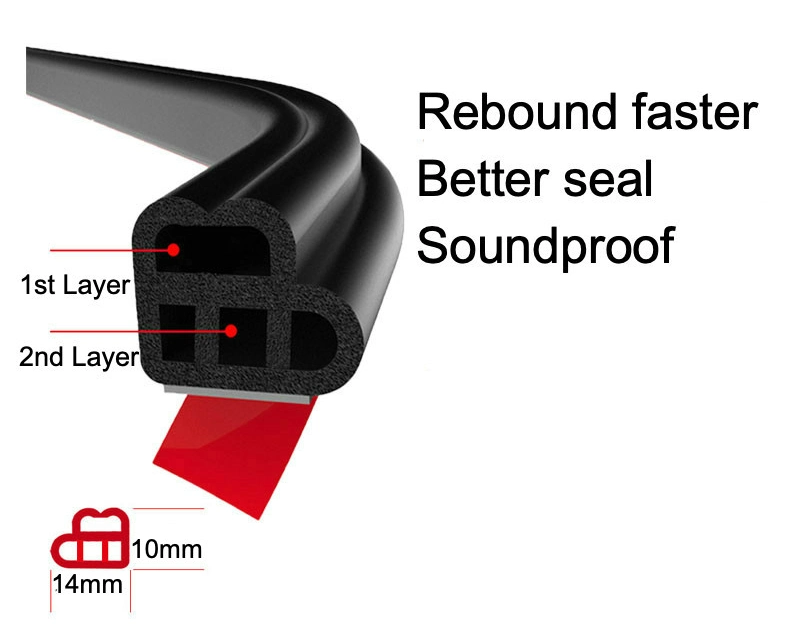

Rubber seals serve multiple purposes in the context of RV slides. Firstly, they provide a protective barrier against the elements, keeping rain, dirt, and debris from entering the interior of the RV. The durability and flexibility of rubber make it an ideal material for this application, as it can withstand various atmospheric conditions without losing its sealing capabilities.

Secondly, rubber seals contribute to thermal insulation. They help maintain a comfortable internal temperature by minimizing the exchange of air between the inside of the RV and the outside environment. This becomes especially important in extreme weather conditions, where maintaining a stable temperature can significantly enhance the comfort level inside the vehicle.

Lastly, rubber seals reduce noise and vibrations when the slide is in use, creating a more pleasant experience for the occupants. Without these seals, occupants might be bothered by the sounds of wind or rain, which can detract from the enjoyment of the RV lifestyle.

Manufacturing Rubber Seals

The manufacturing of rubber seals for RV slides involves several key processes. Understanding these can help manufacturers improve their products and meet the market's growing demands

1. Material Selection Different rubber compounds have varying properties regarding flexibility, durability, and resistance to environmental factors. Manufacturers must choose the right type based on the specific needs of the RV slides and the expected conditions they will face, such as UV exposure and temperature fluctuations.

rubber seals for rv slides manufacturers

2. Design and Engineering Rubber seals must be designed to fit precisely in the designated areas of the RV slide. This involves meticulous design work and the use of CAD software to create accurate models. Additionally, engineers must consider factors like compression resistance to ensure the seal remains effective during operation.

3. Molding Process Once the design is finalized, the next step is the production of the seals, often through a process called injection molding. This method allows for the mass production of seals with consistent quality and performance characteristics.

4. Quality Control Quality assurance is paramount in the manufacturing process. Manufacturers must implement rigorous testing protocols to ensure that the seals meet industry standards for durability and performance. This may include stress tests, environmental tests, and batch inspections.

5. Customization As the RV market diversifies, so do the needs of manufacturers and consumers. Offering customized solutions, whether through different sizes, shapes, or rubber compounds, can give manufacturers a competitive edge in the marketplace.

Considerations for Manufacturers

For manufacturers looking to excel in the production of rubber seals for RV slides, several considerations should be kept in mind

- Market Research Understanding market trends and customer preferences is crucial. Engaging with RV manufacturers and users can provide insight into what improvements or features are desired.

- Sustainability With increasing awareness of environmental issues, exploring eco-friendly materials and sustainable manufacturing processes can attract environmentally conscious consumers.

- Innovation Continuous innovation in materials and production techniques can lead to improved product offerings. Manufacturers should invest in R&D to stay ahead of the competition.

Conclusion

Rubber seals for RV slides play a crucial role in ensuring the functionality and comfort of recreational vehicles. Manufacturers must pay attention to material selection, design, and quality control to produce high-performing seals that meet the diverse needs of the RV market. By staying attuned to industry trends and embracing innovation, they can enhance their offerings and contribute to the growing popularity of RV travel.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025