Jan . 10 , 2025 08:54

Back to list

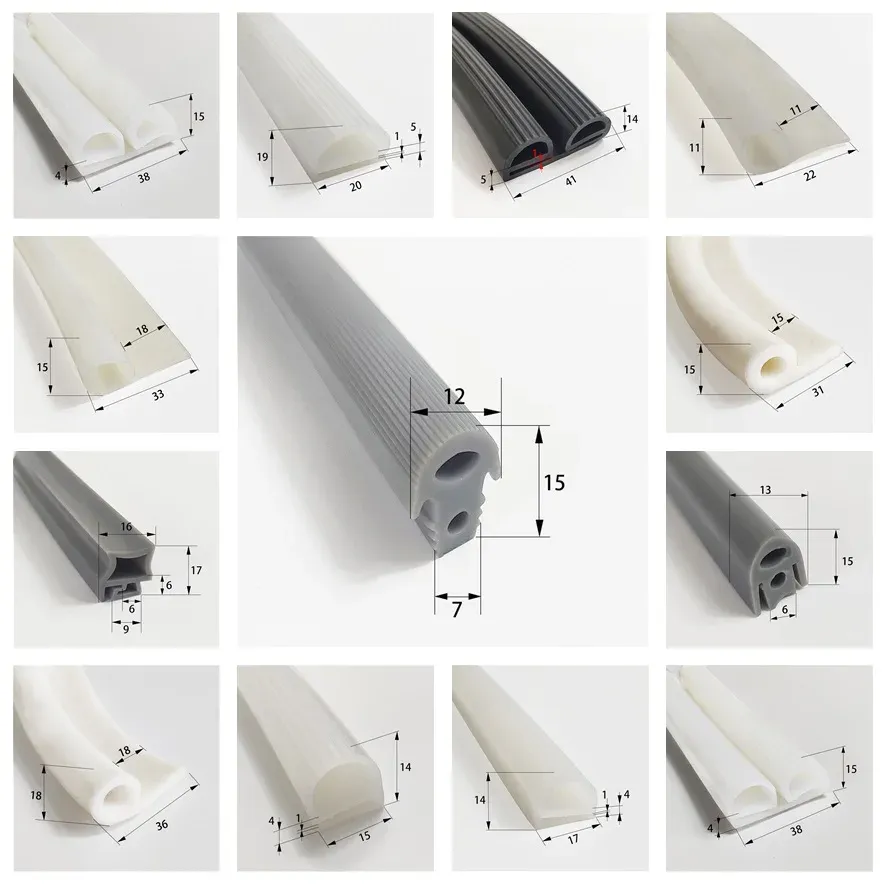

rubber seal strip

Choosing the right rubber seal strip can significantly impact the performance and longevity of various applications, from automotive to industrial uses. Experience with rubber seal strips reveals that not all are created equal; their material, flexibility, and durability play crucial roles in their effectiveness.

Trustworthiness is not just about the product, but also about the sourcing and manufacturing process. Reliable suppliers ensure that their rubber seal strips are produced with high-grade materials, and comply with stringent quality checks. This guarantees that each product performs consistently, providing users peace of mind. Moreover, environmental considerations in the production process contribute to a company's trustworthiness. Utilizing eco-friendly materials and sustainable manufacturing practices not only enhances the product's appeal but also aligns with global efforts to reduce ecological footprints. When selecting a rubber seal strip, consider the application requirements and the specific challenges they might face. Temperature fluctuations, exposure to chemicals, or physical stressors are vital factors influencing your choice. Ensure the strip's dimensions match your needs; a fitting strip will prevent leaks and maintain integrity. In conclusion, a deep-seated expertise in the type of rubber seal strip to use, matched with authoritative manufacturing processes, ensures robust and reliable performance. Trustworthy suppliers who prioritize quality and sustainability add significant value to these essential components across various industries. Whether for automotive or industrial use, the right rubber seal strip ensures optimal function and longevity, leveraging expert knowledge to solve specific challenges efficiently.

Trustworthiness is not just about the product, but also about the sourcing and manufacturing process. Reliable suppliers ensure that their rubber seal strips are produced with high-grade materials, and comply with stringent quality checks. This guarantees that each product performs consistently, providing users peace of mind. Moreover, environmental considerations in the production process contribute to a company's trustworthiness. Utilizing eco-friendly materials and sustainable manufacturing practices not only enhances the product's appeal but also aligns with global efforts to reduce ecological footprints. When selecting a rubber seal strip, consider the application requirements and the specific challenges they might face. Temperature fluctuations, exposure to chemicals, or physical stressors are vital factors influencing your choice. Ensure the strip's dimensions match your needs; a fitting strip will prevent leaks and maintain integrity. In conclusion, a deep-seated expertise in the type of rubber seal strip to use, matched with authoritative manufacturing processes, ensures robust and reliable performance. Trustworthy suppliers who prioritize quality and sustainability add significant value to these essential components across various industries. Whether for automotive or industrial use, the right rubber seal strip ensures optimal function and longevity, leveraging expert knowledge to solve specific challenges efficiently.

Share

Previous:

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025