Top Manufacturers of Rubber and Steel Door Seals for Optimal Protection and Durability

Introduction to Rubber Steel Door Seal Bottom Manufacturers

In various industries, the importance of quality door seals cannot be overstated. Rubber steel door seal bottoms play a crucial role in enhancing the durability, energy efficiency, and overall functionality of door systems. This article explores the significance of rubber steel door seal bottoms, their manufacturing processes, and key manufacturers in the market.

Understanding Rubber Steel Door Seal Bottoms

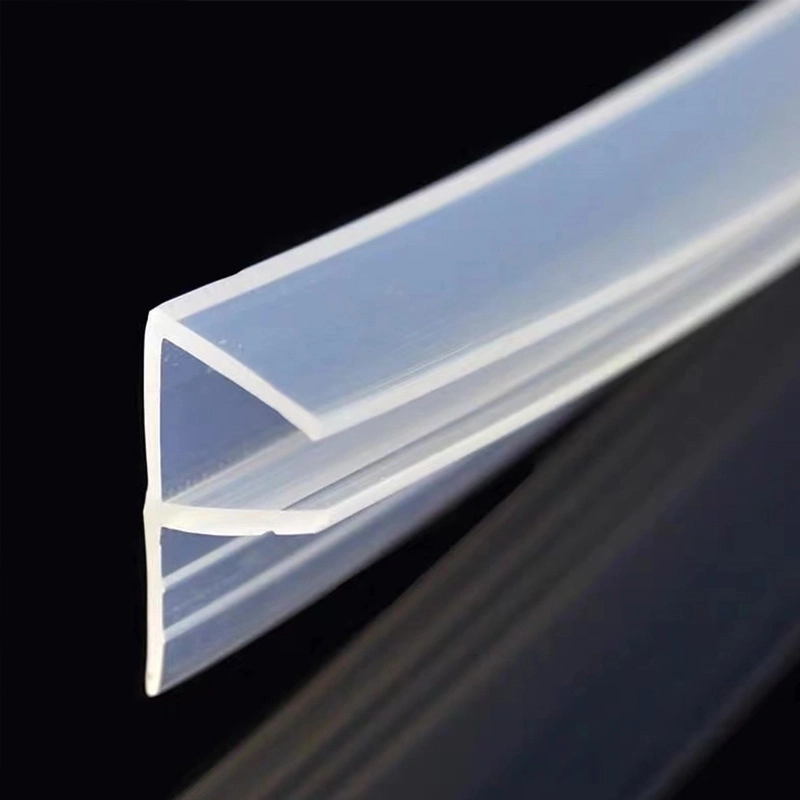

Rubber steel door seal bottoms are specifically designed components that help to seal the gap between the bottom of a door and the ground. They are primarily used in commercial, industrial, and residential settings to ensure a tight seal, preventing the infiltration of dust, dirt, water, and noise. The combination of rubber and steel offers a unique balance of flexibility and strength, ensuring that the door seal maintains its shape and integrity while providing optimal resistance against wear and tear.

Key Benefits of Rubber Steel Door Seal Bottoms

1. Enhanced Insulation One of the most significant benefits of using rubber steel door seal bottoms is their ability to provide thermal insulation. By sealing the gap at the bottom of the door, they help to maintain the indoor temperature, reducing heating and cooling costs. This insulation effect is crucial in both residential and commercial buildings, contributing to energy efficiency and sustainability.

2. Protection Against Elements These door seals act as a barrier against rain, snow, and other environmental factors. They protect the interior of a building from water damage and help maintain a clean environment by preventing dust and debris from entering.

3. Noise Reduction Rubber steel door seal bottoms also play a role in soundproofing. By creating a tighter seal, they help to minimize the transmission of noise from one area to another. This feature is particularly valuable in settings that require confidentiality or reduced noise levels, such as offices, recording studios, and hospitals.

4. Durability and Longevity The combination of rubber and steel ensures that these door seals are both flexible and durable. They withstand heavy usage and resist deterioration from environmental factors, ensuring a long service life.

Manufacturing Processes

rubber steel door seal bottom manufacturers

The manufacturing of rubber steel door seal bottoms involves several steps. First, high-quality rubber compounds are selected based on their resistance to wear, temperature stability, and flexibility. The rubber is then molded into the desired shape, often featuring a steel reinforcement to enhance strength.

In addition to rubber processing, manufacturers employ various techniques such as extrusion, injection molding, and vulcanization to create tailored products that meet specific industry requirements. Quality control measures are crucial at every stage of production to ensure that the final products adhere to industry standards and customer specifications.

Market Overview and Key Manufacturers

The market for rubber steel door seal bottoms has experienced significant growth due to increasing awareness of energy efficiency and environmental sustainability. Numerous manufacturers specialize in the production of these vital components. Some of the leading manufacturers include

1. C.R. Laurence Co., Inc. - A prominent player in the glass and architectural hardware market, C.R. Laurence offers a wide range of door seals and accessories.

2. Pemko Manufacturing Co. - Known for its innovative sealing solutions, Pemko provides products designed for various applications, including rubber steel door seals.

3. Zero International, Inc. - This company focuses on door and window sealing systems, offering durable and effective solutions for noise reduction and energy efficiency.

4. National Guard Products, Inc. - Specializing in weather stripping and door seals, National Guard Products is dedicated to producing high-quality and environmentally friendly sealing solutions.

Conclusion

Rubber steel door seal bottoms are essential components in modern door systems, offering numerous benefits including enhanced insulation, protection from the elements, noise reduction, and long-term durability. With a growing market demand, manufacturers are continuously developing innovative solutions to meet the needs of various industries. As sustainability and energy efficiency become increasingly prioritized, the importance of quality door seals will only continue to rise, underscoring the crucial role played by manufacturers in this sector.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025