Black Rubber Seal Manufacturer for Shower Doors High Quality and Custom Solutions

The Importance of Quality in Shower Door Black Rubber Seal Manufacturing

In the world of shower door manufacturing, the significance of quality components cannot be overstated. Among these essential components, the black rubber seal stands out as a critical element that ensures both functionality and aesthetic appeal. As homeowners and contractors seek the best products for their bathroom spaces, understanding the role and benefits of high-quality black rubber seals becomes paramount.

What is a Shower Door Black Rubber Seal?

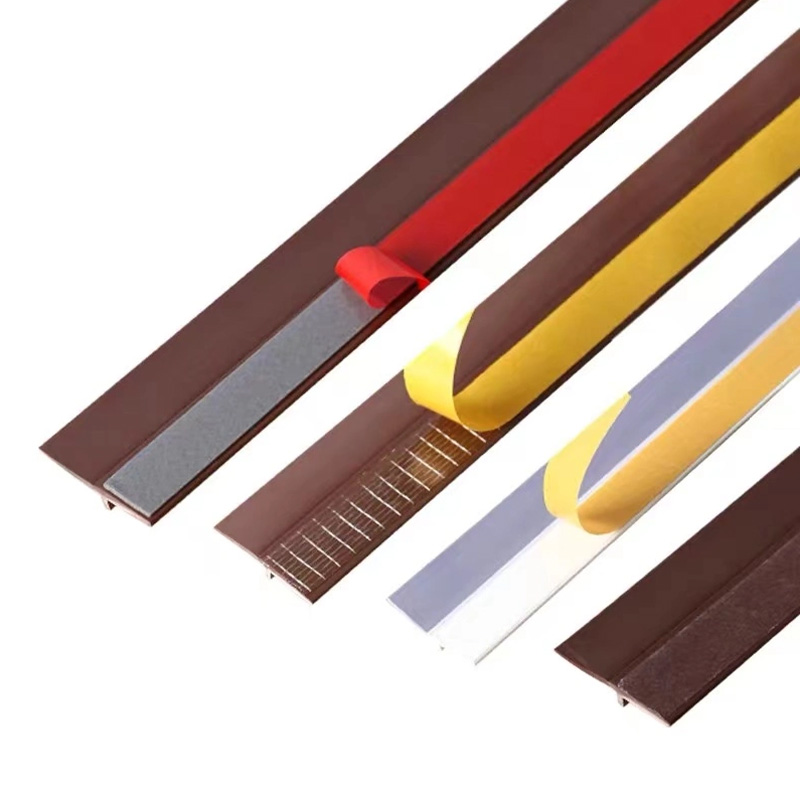

A shower door black rubber seal is a flexible strip that is attached to the edges of shower doors. Its primary function is to prevent water leakage, ensuring that showers remain watertight. Additionally, these seals can also act as sound dampeners, minimizing the noise caused by slamming doors. Beyond functionality, they add a sleek, polished look to the shower door, effortlessly complementing modern bathroom designs.

Manufacturing Process and Quality Assurance

The manufacturing of black rubber seals involves several stages, each of which contributes to the final product's quality. Premium manufacturers typically start with high-grade materials, such as EPDM (Ethylene Propylene Diene Monomer) rubber, known for its durability and resistance to water, heat, and UV rays. This raw material selection is crucial, as it directly affects the seal's longevity and performance.

Once the material is sourced, the manufacturing process includes extrusion, molding, and cutting. Advanced machinery is employed to ensure precision in shaping the rubber into the desired profiles. Quality control measures are implemented at various stages, including testing for flexibility, tensile strength, and resistance to degradation over time. This rigorous process ensures that the end product meets the high standards expected by consumers and builders alike.

Why Choose Black Rubber Seals?

shower door black rubber seal manufacturer

Opting for black rubber seals for shower doors offers multiple advantages. First and foremost, the color black is not only stylish but also practical, as it effectively hides stains and wear over time. This feature is particularly beneficial in high-moisture environments where cleaning can be a hassle.

Moreover, black rubber seals provide excellent insulation properties, keeping showers warmer and minimizing the risk of condensation build-up. This not only enhances comfort during use but also helps prevent slippery surfaces that can lead to accidents.

The Competitive Edge of Quality Manufacturers

As the demand for quality bathroom fixtures rises, the competition among seal manufacturers intensifies. Those manufacturers that prioritize superior materials, advanced manufacturing technology, and efficient production techniques often stand out. They tend to offer longer warranties and better customer service, establishing their reputation within the industry.

Quality manufacturers often engage in continuous research and development to innovate and improve their products. By staying attuned to market trends and consumer preferences, they can produce shower door seals that not only meet today’s demands but also anticipate future needs.

Conclusion

In conclusion, the shower door black rubber seal is a small but crucial component that plays a significant role in the overall quality and functionality of bathroom installations. By choosing high-quality seals from reputable manufacturers, consumers can ensure their shower doors are leak-proof, stylish, and durable. As the market continues to evolve, the importance of quality manufacturing processes will remain a key factor for anyone involved in the design and construction of modern bathrooms. Investing in quality shower door seals ultimately translates to peace of mind, superior performance, and long-lasting satisfaction.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025