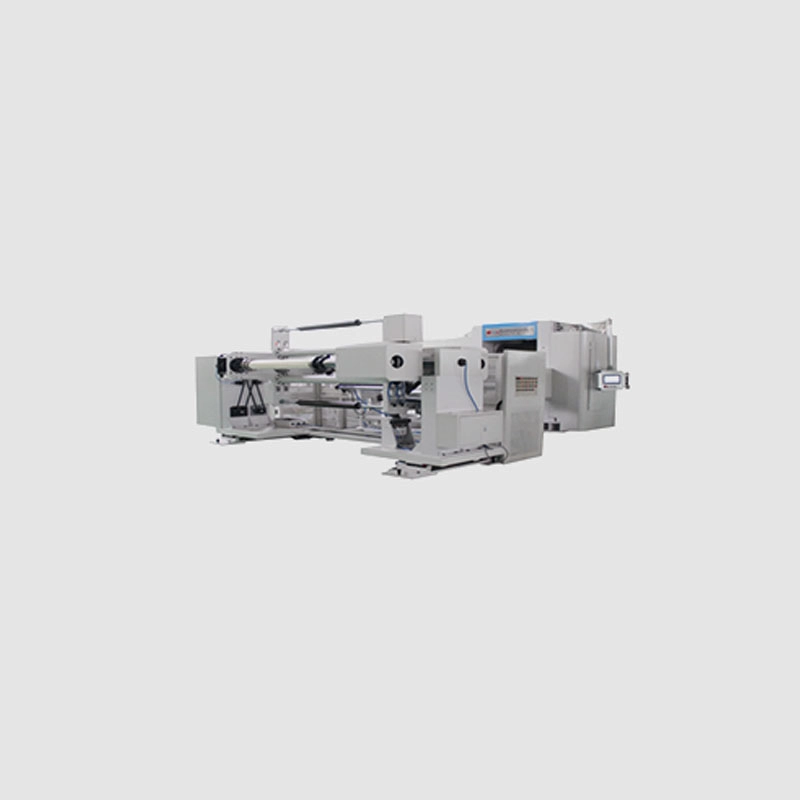

slitting machine

Understanding Slitting Machines An Essential Tool in Manufacturing

In the world of manufacturing, efficiency and precision are paramount. Among the various machines that aid in this quest for productivity, the slitting machine stands out as a critical device in the processing of materials, particularly in industries dealing with flexible materials such as paper, plastic films, and metallic sheeting. This article aims to provide an in-depth overview of slitting machines, their functionality, applications, and the advantages they offer in modern manufacturing.

What is a Slitting Machine?

A slitting machine is a specialized piece of equipment that cuts large rolls of material, known as parent rolls or master rolls, into narrower rolls or sheets. The process involves slicing the parent roll with precision blades to achieve desired widths, allowing for the efficient handling, packaging, and utilization of materials. Slitting machines can be designed for various materials, including paper, adhesive tapes, textiles, and even metals, making them versatile in their applications.

How Do Slitting Machines Work?

The operation of a slitting machine typically involves several key components unwind stands, cutting systems, and rewind stands. The process begins with the unwinding of the master roll. Once the material is fed into the machine, it passes through a series of rotary knives or blades arranged in a particular alignment. These blades slice through the material to create multiple narrower rolls.

In more advanced slitting machines, there might be additional features such as automatic tension control systems, which help maintain consistent pressure throughout the process, ensuring high-quality cuts. Some machines also incorporate laser or ultrasonic technology to enhance cutting efficiency and precision. After the material is sliced, it is wound back onto smaller rolls, ready for further processing or shipment.

Applications of Slitting Machines

slitting machine

Slitting machines find applications across various industries due to their adaptability. In the packaging industry, they are used to convert large rolls of plastic or paper into smaller rolls suitable for production lines. In the textile industry, slitting machines can cut fabric into strips for garment manufacturing or create rolls for upholstery.

Moreover, the automotive and electronics sectors rely on slitting machines to produce components from various materials, including metals and insulation films. As industries continue to evolve, the need for customized materials will likely increase, further solidifying the role of slitting machines in manufacturing processes.

Advantages of Using Slitting Machines

The benefits of incorporating slitting machines into a production line are manifold. Firstly, these machines enhance operational efficiency. By automating the cutting process, they minimize labor costs and reduce the time required to produce narrower rolls. This automation also lowers the risk of human error, ensuring that products are consistently cut to precise specifications.

Secondly, slitting machines contribute to material conservation. By producing smaller rolls from larger ones, manufacturers can optimize the usage of raw materials and reduce waste. This not only has economic benefits but also aligns with sustainability goals, as less waste contributes to a smaller environmental footprint.

Additionally, modern slitting machines often come equipped with advanced quality control features, allowing manufacturers to monitor the cutting process in real time. This capability ensures that any deviations from specified tolerances can be addressed immediately, preserving product integrity.

Conclusion

In summary, slitting machines are an invaluable asset in modern manufacturing, providing efficiency, precision, and versatility in material handling. As industries demand higher levels of customization and quicker production times, the importance of slitting machines will continue to grow. Companies looking to enhance their manufacturing processes would do well to consider the benefits of incorporating slitting technology into their operations. The investment in advanced slitting machines not only streamlines production but also aligns with broader goals of sustainability and quality assurance, positioning businesses for success in a competitive market.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025