Suppliers for Square Section Rubber Seals in Various Industries and Applications

The Importance of Square Section Rubber Seals in Various Industries

Rubber seals play a crucial role in ensuring the integrity and functionality of various mechanical systems. Among them, square section rubber seals have gained prominence due to their unique design and versatility. This article will delve into the significance of square section rubber seals, their applications, and the notable suppliers in the industry.

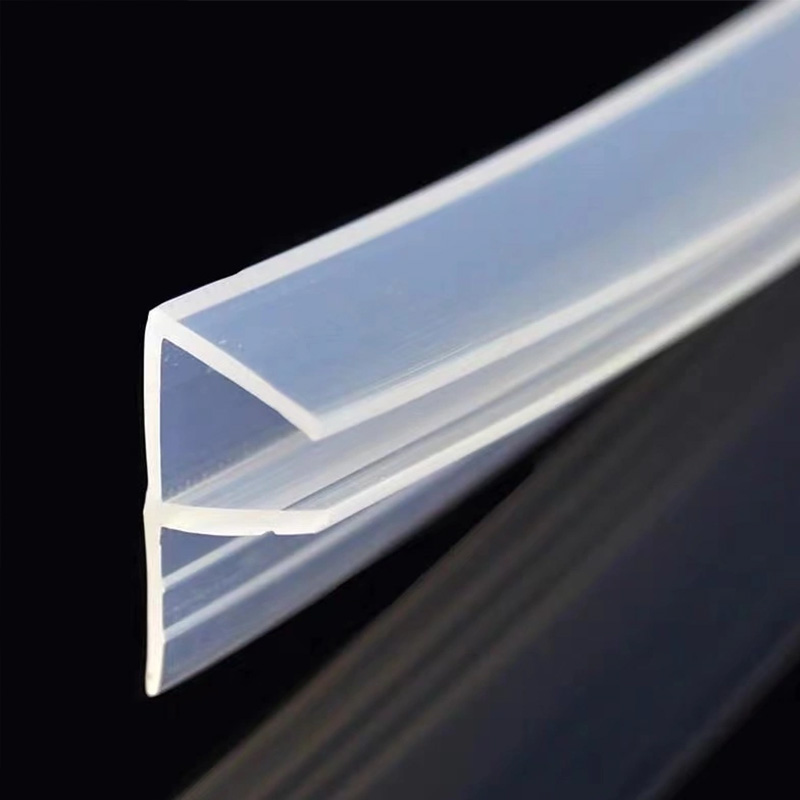

Understanding Square Section Rubber Seals

Square section rubber seals are designed with a square cross-sectional shape, making them ideal for providing a tight seal in applications where traditional O-rings might not suffice. The geometric configuration of these seals allows for a larger surface area to come into contact with the sealing surfaces, which results in better sealing capacity and durability against extreme conditions.

These seals are often made from high-quality elastomers, such as nitrile, silicone, or EPDM, which confer their resilience and resistance to various environmental factors, including temperature fluctuations, chemicals, and ozone. The choice of material greatly affects the performance of the seal, making it imperative for industries to source seals that meet their specific operational requirements.

Applications of Square Section Rubber Seals

Square section rubber seals find applications across diverse sectors. Here are some of the most notable

1. Automotive Industry In vehicles, they are used in windows, doors, and engine components. Their ability to withstand high pressures while providing effective sealing against dust, water, and noise makes them invaluable.

2. Aerospace The aerospace sector requires seals that can endure extreme temperatures and pressures. Square section rubber seals are employed in hydraulic systems and fuel tanks to prevent leaks and maintain system integrity.

4. Electronics With the rise of portable and wearable electronics, the need for robust sealing solutions has surged. Square section rubber seals are used in casings and enclosures to safeguard sensitive electronic components from moisture and dust.

square section rubber seals suppliers

Choosing the Right Supplier

With a plethora of suppliers in the market, selecting the right source for square section rubber seals is paramount for ensuring quality and reliability. When evaluating suppliers, consider the following factors

1. Material Quality Ensure that the supplier uses high-grade materials that meet industry standards and regulations.

2. Customization Options Different applications might require specific dimensions, materials, or properties. A good supplier should offer customization to cater to unique needs.

3. Reputation and Reviews Research customers' feedback on suppliers to ascertain their reliability, quality of products, and customer service.

4. Technical Support A reputable supplier should provide technical assistance during product selection and installation, ensuring that clients choose the best seals for their applications.

5. Certifications Look for suppliers with relevant industry certifications, which can serve as indicators of their commitment to quality and industry standards.

6. Price Competitiveness While quality is paramount, suppliers that offer competitive pricing without compromising on quality would provide better value.

Conclusion

Square section rubber seals are essential components in many industries, providing critical sealing solutions that ensure operational efficiency and equipment longevity. As industries grow and evolve, the demand for reliable suppliers who can provide high-quality rubber seals becomes increasingly vital. By focusing on material quality, customization, and supplier reputation, businesses can secure the best products to meet their sealing needs. The right rubber seal can make all the difference in performance, safety, and cost-effectiveness, making it imperative for industries to prioritize quality in their choices.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025