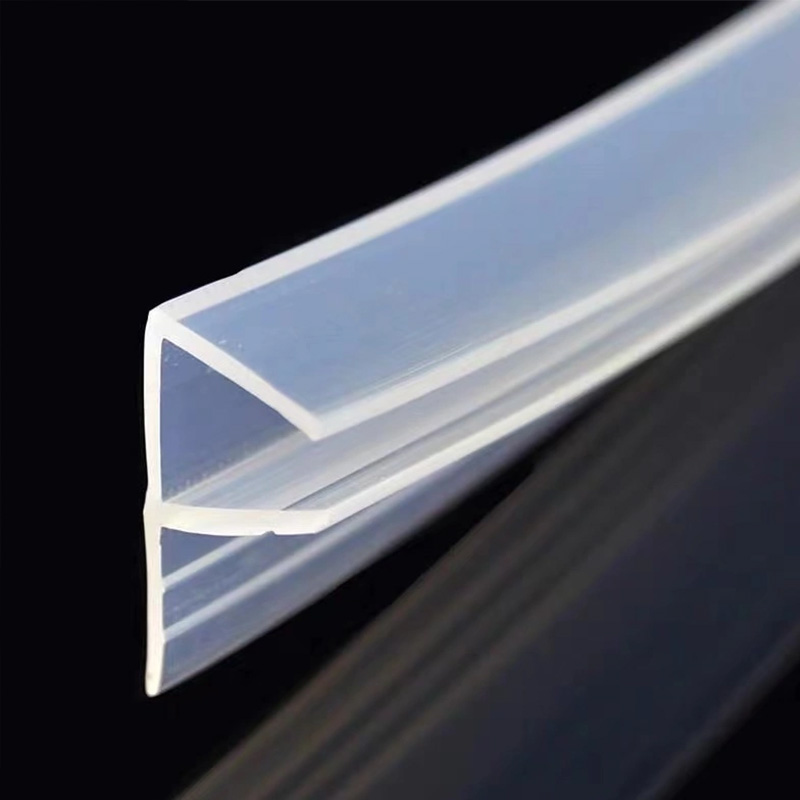

s type rubber seal strip

Understanding S-Type Rubber Seal Strips Essential Components for Enhanced Sealing Solutions

In today’s fast-paced industrial and commercial environments, the importance of effective sealing solutions cannot be overstated. One of the most versatile and widely used sealing solutions is the S-type rubber seal strip. This article delves into the characteristics, applications, and benefits of S-type rubber seal strips, illustrating why they are a preferred choice in a variety of sectors.

What is an S-Type Rubber Seal Strip?

S-type rubber seal strips are specifically designed sealing elements characterized by their S-shaped cross-section. This unique shape allows them to provide a tight seal against moisture, dust, air, and other environmental factors. The S-type seal is typically made from high-quality rubber materials, which can include natural rubber, neoprene, EPDM, or silicone. These materials are chosen for their durability, flexibility, and resistance to varying temperatures and environmental conditions.

Key Characteristics

1. Flexible Design The S-shaped profile of these seal strips allows for excellent flexibility, enabling them to conform to irregular surfaces and providing a snug fit. This adaptability is crucial in many applications where standard seals may not be effective.

2. Durability Made from robust rubber materials, S-type seal strips are designed to withstand harsh conditions, including exposure to UV rays, ozone, and chemicals. This durability makes them suitable for both indoor and outdoor applications.

3. Versatile Applications S-type rubber seal strips can be used in a broad range of applications, including automotive, construction, appliances, and manufacturing. They are effective in sealing gaps in doors, windows, machinery, and HVAC systems, preventing air and water infiltration.

s type rubber seal strip

4. Sound Insulation In addition to sealing, these strips also provide sound insulation, making them ideal for use in environments where noise reduction is a priority, such as in residential buildings or recording studios.

Applications Across Industries

1. Automotive Industry In vehicles, S-type rubber seal strips are commonly used around doors, trunks, and windshields. They prevent water leakage, reduce wind noise, and enhance passenger comfort. Their ability to withstand the rigors of daily wear and tear makes them essential for vehicle longevity.

2. Construction In construction, these seal strips play an important role in ensuring that buildings are airtight and watertight. They are used in windows and doors to provide thermal insulation, which is crucial for energy efficiency and maintaining comfortable indoor temperatures.

3. Manufacturing S-type rubber seal strips are prevalent in manufacturing settings, where they seal machinery components to prevent dust, dirt, and other contaminants from entering sensitive areas. Maintaining cleanliness in these environments is vital for product quality and operational efficiency.

4. Home Appliances Many household appliances, such as refrigerators and ovens, utilize S-type rubber seals to prevent heat loss and maintain energy efficiency. This not only reduces energy costs but also improves the appliance’s performance.

Conclusion

S-type rubber seal strips are indispensable components in modern sealing solutions. Their unique design, combined with the adaptability and durability of rubber materials, allows them to solve various sealing challenges across multiple industries. As companies strive to enhance energy efficiency, reduce noise, and maintain optimal operational conditions, the demand for effective sealing solutions like S-type rubber seal strips will continue to grow. Investing in quality sealing products can result in significant long-term benefits, including cost savings and improved product performance. Whether in vehicles, buildings, or industrial applications, S-type rubber seal strips exemplify the blend of functionality and reliability that modern sealing technologies offer.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025