three-square file manufacturer

Three-Square File Manufacturer Crafting Precision Tools for Metalworking

In the intricate world of metalworking and manufacturing, the significance of high-quality tools cannot be overstated. One of the most essential tools used in this domain is the three-square file. Renowned for its efficiency in shaping, refining, and finishing metal surfaces, the three-square file has become a cornerstone for craftsmen, engineers, and hobbyists alike. This article delves into the prowess of three-square file manufacturers, exploring their vital role in ensuring tool quality, innovation, and producer-consumer dynamics.

What is a Three-Square File?

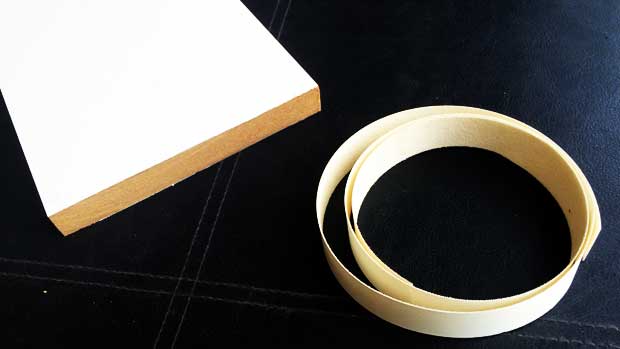

A three-square file, also known as a triangle file, is a tapered tool shaped like a triangle in cross-section. This unique shape allows it to reach into corners and narrow spaces that other files cannot, making it invaluable for tasks requiring precision. The surfaces of the file can be single-cut or double-cut, enabling various levels of metal removal, from aggressive material shaping to fine finishing.

The Role of Manufacturers

Three-square file manufacturers play an essential role in producing these tools with meticulous attention to detail. They utilize high-grade materials such as high-carbon steel or carbide to ensure durability and effectiveness. The manufacturing process often involves sophisticated techniques such as forging, heat treatment, and precision grinding. Each file must meet strict quality standards to ensure consistency and performance across production batches.

Quality Control

Quality control is paramount in the production of three-square files. Manufacturers implement rigorous testing protocols to assess the files' hardness, cutting ability, and overall functionality. This usually involves both visual inspections and practical tests on different materials. A reputable file manufacturer will provide specifications and certifications that guarantee the reliability of their products, giving consumers confidence in their purchase.

three-square file manufacturer

Technological Advancements

In recent years, advancements in technology have significantly impacted how three-square files are manufactured. Increased use of computer numerical control (CNC) machines allows for higher precision in creating these tools, reducing human error and enhancing repeatability. Additionally, manufacturers are beginning to explore innovative materials and coatings that improve wear resistance and prolong the lifespan of the files. This ongoing commitment to research and development ensures that three-square file manufacturers remain at the forefront of the industry.

Customization and Versatility

One of the key offerings from reputable three-square file manufacturers is customization. Many manufacturers understand that different users have diverse needs, whether they are working on delicate jewelry projects or heavy machinery. Customized files can be produced in various sizes, coarseness, and lengths to cater to specific applications. This versatility not only broadens the manufacturer’s market reach but also fosters loyalty among consumers who require precision tools tailored to their unique projects.

Market Dynamics and Consumer Relations

The relationship between three-square file manufacturers and consumers is evolving. In the age of e-commerce, manufacturers are increasingly adopting direct sales strategies, allowing them to engage with end-users more effectively. This direct line of communication ensures that manufacturers can receive feedback, understand consumer needs, and make necessary adjustments to their product offerings. Furthermore, many manufacturers invest in educational content and resources, aiding consumers in selecting the right tools for their tasks.

Conclusion

Three-square file manufacturers are pivotal in the metalworking industry, providing essential tools that empower craftsmen to create, innovate, and refine their work. Through a commitment to quality, technological advancement, and customer satisfaction, these manufacturers not only contribute to the efficiency and effectiveness of metalworking processes but also play a significant role in advancing the industry as a whole. As the demand for precision tools continues to grow, the expertise and dedication of three-square file manufacturers will be instrumental in shaping the future of metalworking.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025