trailer slide out rubber seals factories

Understanding Trailer Slide-Out Rubber Seals Importance and Manufacturing Insights

When it comes to increasing the functionality and durability of trailers, particularly those equipped with slide-out sections, the role of rubber seals cannot be overstated. These components are essential not only for providing a watertight seal but also for protecting the interior from dust, debris, and pests. With the rising popularity of recreational vehicles (RVs) and expandable trailers, the demand for high-quality trailer slide-out rubber seals has surged, leading to the establishment of specialized factories.

The Role of Rubber Seals in Trailers

Trailer slide-out rubber seals are strategically placed along the edges of slide-out rooms, which extend outward to create additional living space. These seals are designed to compress when the slide-out is in use, ensuring a tight fit against the trailer body. This compression prevents water leaks and air infiltration, contributing to the overall comfort and safety of the interior.

Without effective rubber seals, trailers become vulnerable to a myriad of issues. Water ingress can lead to mold growth, structural damage, and the decay of interior furnishings. Additionally, poor sealing can compromise the insulation of the living space, leading to increased energy consumption and higher operational costs. Therefore, investing in high-quality rubber seals is essential for any trailer owner seeking longevity and reliability.

Manufacturing Process of Rubber Seals

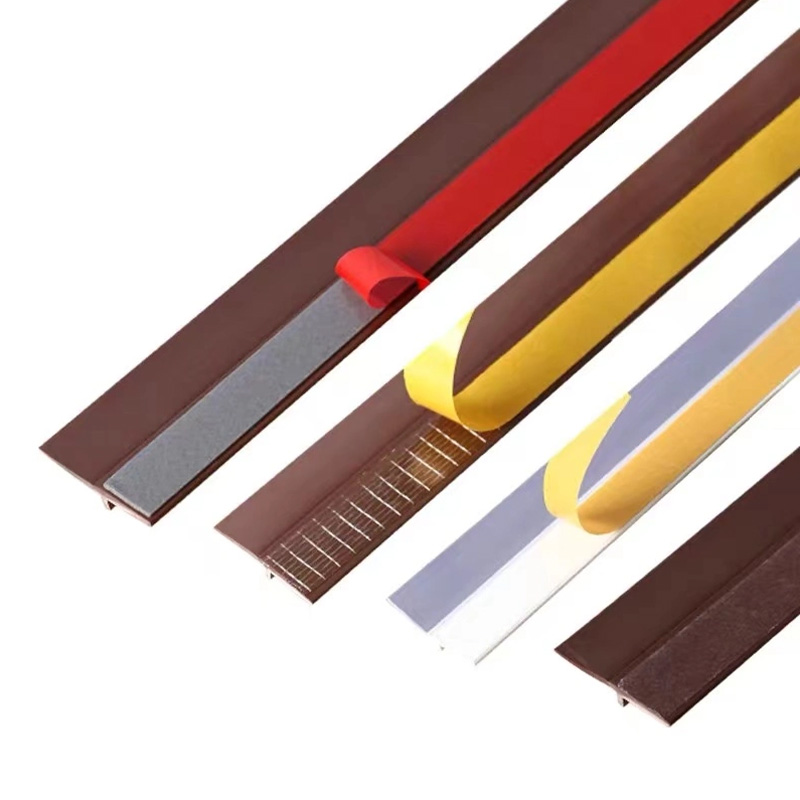

The manufacturing of trailer slide-out rubber seals involves several key steps. This process typically begins with the selection of high-quality rubber compounds designed for durability and resilience. These compounds are specifically formulated to withstand varying weather conditions, UV exposure, and wear over time.

trailer slide out rubber seals factories

After selecting the appropriate materials, the rubber is shaped into the required profile using advanced extrusion processes. This method ensures that the seals are uniform in size and made to fit the specific dimensions of different trailer models. Once extruded, the rubber seals undergo curing, which enhances their elasticity and strength.

Quality control is a crucial aspect of the manufacturing process. Factories perform rigorous testing on the finished products to ensure they meet industry standards for performance and longevity. Tests often include assessing the seals' resistance to aging, temperature variations, and mechanical stress.

The Importance of Choosing a Reputable Factory

When selecting rubber seals for trailers, it’s vital for manufacturers and consumers to partner with reputable factories. A reliable factory will not only use high-quality materials but will also adhere to stringent manufacturing processes that ensure product consistency and performance.

Additionally, many leading factories invest in research and development to innovate and improve their sealing products continually. This focus on innovation can lead to advancements in seal designs that enhance waterproofing capabilities and improve ease of installation.

Conclusion

In conclusion, trailer slide-out rubber seals are a critical component in the construction of functional and durable trailers. The manufacturing of these seals involves meticulous processes that ensure their effectiveness in protecting against water and air leaks. As the demand for trailers continues to grow, collaborating with advanced and reputable rubber seal factories will be key for manufacturers looking to provide top-notch products. Ultimately, investing in high-quality rubber seals is an investment in the longevity and comfort of the trailer experience.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025