Manufacturer of Triangular File Sizes and Specifications for Precision Tooling

Understanding Triangular File Dimensions A Guide for Manufacturers

Triangular files, also known as triangular saw files, are essential tools in machining, woodworking, and metalworking industries. These files are characterized by their three-edged design, which allows for the creation of sharp angles and fine details. Understanding the dimensions and configurations of triangular files is crucial for manufacturers looking to optimize production processes and meet specific customer needs.

Key Dimensions of Triangular Files

The dimensions of triangular files can be categorized into several key features overall length, blade length, width, and tooth size or pitch. Each of these dimensions plays a significant role in the file’s performance and suitability for particular tasks.

1. Overall Length The overall length of the file typically ranges from 6 inches to 12 inches, though longer variations exist. The length of the file impacts the leverage and control during usage. Longer files can cover more surface area, while shorter files offer greater precision for intricate work.

2. Blade Length Blade length refers to the working section of the file that engages with the material. This dimension directly influences the depth of cut and the type of applications the file can handle. Manufacturers often tailor the blade length to fit specific tools or machinery, ensuring compatibility and effectiveness.

3. Width The width of a triangular file varies depending on its intended use. Standard widths may range from 1/4 inch to 1 inch. Narrower files are preferred for detailed engraving and delicate work, while wider files are suited for heavy material removal.

4. Tooth Size or Pitch The tooth size, or pitch, is a crucial aspect of the file's texture, determining the cutting action and finish quality. Files with coarser teeth (lower pitch) are designed for rapid material removal, while those with finer teeth (higher pitch) provide a smoother finish suitable for finishing tasks.

triangular file dimensions manufacturer

Material Considerations

Triangular files are typically made from high-carbon steel or hardened steel, providing durability and resistance against wear. Some manufacturers also produce files with special coatings, such as titanium or ceramic, to enhance longevity and performance. The choice of material impacts not only the file's lifespan but also its effectiveness in various applications.

Applications of Triangular Files

Triangular files find use in a wide array of applications, making them indispensable tools for manufacturers. Common uses include

- Sharpening Edges Their unique shape allows for effective sharpening of edges in tools, blades, and various mechanical components. - Detail Work They are frequently employed in detail work involving curvatures and angles, especially in intricate wood and metal designs. - Material Preparation Triangular files aid in preparing surfaces for further finishing and treatment processes.

Conclusion

In summary, the dimensions of triangular files play a critical role in their functionality and effectiveness. Manufacturers must pay attention to various factors such as overall length, blade length, width, and tooth size to select the appropriate file for specific applications. By understanding these dimensions, manufacturers can optimize their production processes and better serve their customers' diverse needs. Whether for sharpening, detailing, or material preparation, triangular files remain essential tools in the toolkit of any professional craftsman or industrial operator. Proper selection and use of these tools can lead to significant improvements in both efficiency and quality of work.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

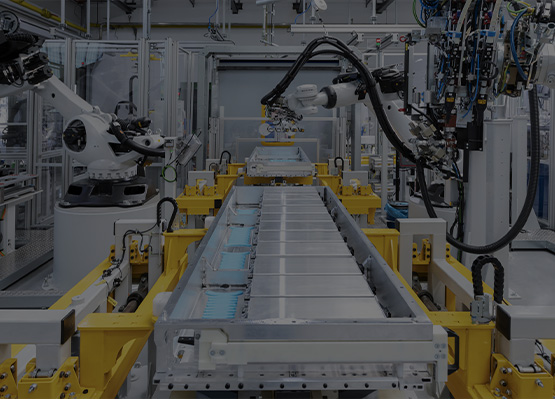

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025