t type rubber seal

Understanding T-Type Rubber Seals Design, Applications, and Benefits

Rubber seals are an essential component in various industries, providing an effective solution for preventing leaks, protecting against environmental contaminants, and ensuring operational efficiency. Among the variety of rubber seals available, the T-type rubber seal stands out due to its unique design and versatile applications. In this article, we will explore the characteristics, uses, and advantages of T-type rubber seals, highlighting their importance in various sectors.

What is a T-Type Rubber Seal?

A T-type rubber seal features a cross-section that resembles the letter T. This design allows for efficient sealing in applications where a secure fit is crucial. The T-shape is particularly effective for applications that require the seal to fit snugly into a groove or channel, providing a barrier against fluids, gases, and other contaminants. Typically made from high-quality elastomers, such as silicone or EPDM (ethylene propylene diene monomer), T-type rubber seals offer excellent flexibility, durability, and resistance to various environmental factors.

Applications of T-Type Rubber Seals

The versatility of T-type rubber seals allows them to be employed in a wide range of industries, including

1. Automotive Industry In vehicles, T-type seals are commonly used around doors, windows, and hoods to prevent water and air leakage. They help to enhance aerodynamics, improve fuel efficiency, and maintain a comfortable cabin environment. Additionally, they are integral to vibration dampening, contributing to a smoother ride.

2. Construction and Architecture T-type seals are often utilized in building construction, particularly in windows and doors, to waterproof structures and improve energy efficiency. They create airtight seals that reduce heating and cooling costs while also providing sound insulation.

3. Manufacturing and Machinery In industrial applications, these seals protect machinery components from dust, moisture, and other environmental pollutants. By maintaining an effective seal, T-type seals help to prolong the lifespan of machinery and reduce maintenance costs.

4. Electronics With the increasing demand for electronic devices to withstand harsh environments, T-type rubber seals are often employed in sealing electrical enclosures, connectors, and other components. This helps to safeguard against moisture and dust ingress, ensuring reliable performance.

t type rubber seal

Advantages of T-Type Rubber Seals

T-type rubber seals offer several advantages that make them a preferred choice in various applications

1. Effective Sealing The unique T-shape design allows for a tight fit, creating a reliable seal against unwanted leaks. This characteristic is particularly important in applications where precision is critical.

2. Durability Made from resilient rubber materials, T-type seals can withstand a wide range of temperatures and environmental conditions. They are resistant to UV rays, chemicals, and ozone, ensuring long-lasting performance even in challenging situations.

3. Flexibility The elasticity of the rubber materials allows T-type seals to conform to irregular surfaces, enhancing their sealing capability. This flexibility makes them suitable for dynamic applications where movement occurs.

4. Ease of Installation T-type seals are relatively easy to install, requiring minimal tools and expertise. This ease of installation can result in significant labor cost savings during assembly or maintenance.

5. Cost-Effective Solution By preventing leaks and protecting machinery or components, T-type seals can significantly reduce operational costs. The longevity and durability of these seals mean less frequent replacements, contributing to overall cost efficiency.

Conclusion

In conclusion, T-type rubber seals play a vital role in various industries by providing efficient sealing solutions that enhance performance and protect against environmental factors. Their unique design, combined with their flexibility and durability, makes them an ideal choice for applications ranging from automotive to electronics. As industries continue to evolve and demand more reliable sealing solutions, T-type rubber seals will remain a crucial component in maintaining operational efficiency and safety. Whether you're involved in manufacturing, construction, or any other sector requiring effective sealing technologies, understanding the advantages of T-type rubber seals is essential for optimizing your processes and products.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

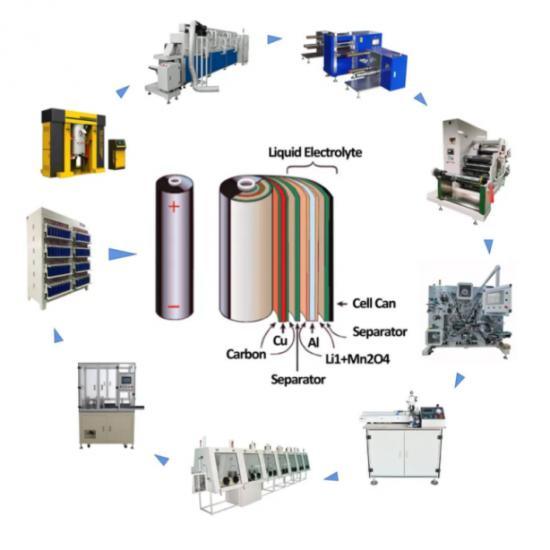

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025