Windshield Rubber Sealing Strip - Weatherproof, Durable & Easy Install

XINGTAI SHUODING TRADING CO.,LTD

Professional Manufacturer of Premium Automotive Sealing Solutions

📍 Address: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China

📱 Phone: 86-19803295498

✉️ Email: sdtrading0927@126.com

🌐 Website: www.xtshuoding.com

Industry Evolution of Windshield Sealing Technology

The automotive sealing industry has undergone significant transformation, with windshield rubber sealing strips becoming a critical component in vehicle safety and performance. According to the International Rubber Study Group, the global market for automotive rubber components is projected to reach $74 billion by 2026, driven by increasing vehicle production and stringent safety regulations.

Windshield rubber sealing strips serve multiple functions beyond their primary sealing capability. These components now contribute to vehicle aerodynamics, reducing wind noise and drag by up to 15% according to SAE International research (SAE Technical Paper 2021-01-0359). Modern designs also incorporate ultraviolet resistance additives to withstand solar degradation and maintain structural integrity throughout the vehicle's lifecycle.

Manufacturers like XINGTAI SHUODING have pioneered co-extrusion techniques that combine multiple rubber compounds within a single profile. This innovation allows for optimal properties throughout the seal's structure: the surface layer can provide excellent weathering resistance while the core maintains excellent compression set characteristics. Such developments demonstrate how windshield sealing technology continues to evolve beyond its traditional role.

Product Spotlight

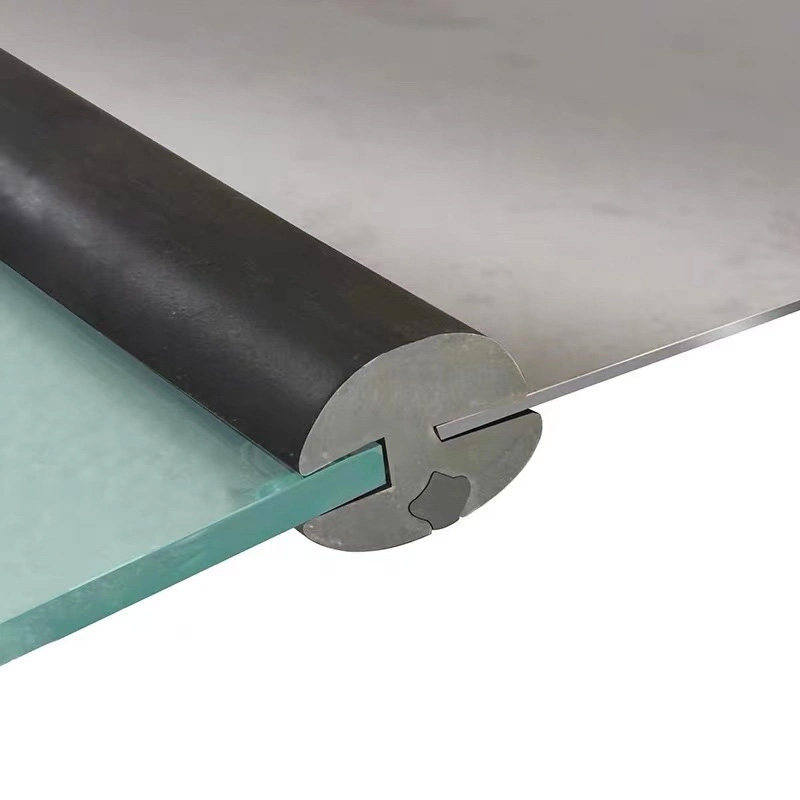

Windshield rubber sealing strip by XINGTAI SHUODING TRADING CO.,LTD represents the forefront of sealing technology with its innovative design and material engineering. Place of Origin: Hebei, China | Model Number: SD-001

Advanced Material Composition

The product is manufactured using various high-performance elastomers tailored to specific application requirements:

Technical Specifications of Windshield Rubber Sealing Strip

| Parameter | Test Standard | Value Range | Units |

|---|---|---|---|

| Tensile Strength | ASTM D412 | 12 - 20 | MPa |

| Elongation at Break | ASTM D412 | 350 - 550 | % |

| Hardness (Shore A) | ASTM D2240 | 65 - 85 | Shore A |

| Compression Set | ASTM D395 | 15 - 30 | % |

| Temperature Range | ISO 188 | -50°C to +150°C | Degrees |

| Water Absorption | ISO 62 | < 5 | % |

| Weathering Resistance | ASTM G154 | 3000+ hours | Hours |

Engineering Excellence in Material Science

The fundamental performance attributes of windshield rubber sealing strips are determined by compound formulations. Recent innovations have focused on developing specialized elastomers that overcome traditional material limitations while maintaining production efficiency:

EPDM Compounds remain the industry standard for weather-resistant applications due to their excellent ozone, UV, and thermal resistance. However, advancements in EPDM polymer architectures have created significant improvements. The development of long-chain branching techniques has enhanced melt strength during extrusion while maintaining critical physical properties. These new formulations have enabled faster production speeds without compromising final product dimensions or quality.

For sealing applications requiring enhanced resistance to petroleum-based fluids, specialty NBR/PVC Blends have become the preferred solution. These formulations incorporate unique plasticizer packages with lower migration tendencies and improved low-temperature flexibility to -40°C. Research from the Rubber Institute of Technology demonstrates that contemporary NBR/PVC compounds exhibit oil resistance improvements of up to 50% over previous generations while maintaining essential sealing force retention.

Silicone Rubber Formulations represent the premium solution for extreme temperature applications ranging from -70°C to +230°C. Recent innovations in platinum-cured liquid silicone rubber (LSR) processing have enabled complex geometries with precise dimensional control. These manufacturing advancements have accelerated the adoption of silicone solutions in performance automotive applications where reliability under harsh conditions is paramount.

Technical Q&A: Windshield Sealing Solutions

What are the critical considerations for seal compression force in windshield applications?

Optimal compression force balances water ingress protection with installation feasibility. Industry standards (ISO 37:2017) recommend a compression force between 15-25 N/100mm. Our windshield rubber sealing strip is engineered to maintain 17-22 N/100mm after thermal aging to ensure long-term performance.

How does the molecular structure of EPDM rubber contribute to weather resistance?

The saturated polymer backbone in EPDM (ethylene propylene diene monomer) lacks double bonds vulnerable to ozone and UV degradation. This structural characteristic enables superior weathering resistance compared to unsaturated elastomers like natural rubber.

What factors determine proper seal cross-section design?

Critical factors include glass curvature radius, body panel tolerances (±1.5mm typically), required compression deflection (30-40% recommended), and water drainage requirements. Our SD-001 model incorporates patented hollow chambers to optimize compression while reducing material usage.

What certifications should quality windshield seals carry?

Quality seals should comply with ISO 9001 for manufacturing, IATF 16949 for automotive quality management, and specific material certifications such as UL 94 V-0 for flame resistance and RoHS compliance for hazardous substances.

How is noise reduction quantified in modern sealing systems?

Wind noise performance is measured in acoustic wind tunnels according to SAE J1073 standards. Premium windshield seals reduce cabin noise by 2-3 dB across frequency ranges of 500-4000 Hz through optimized sealing contact geometry.

What accelerated aging tests are used to predict seal lifespan?

Standardized testing includes heat aging (ISO 188:2011), weathering resistance (ISO 4892-2), ozone resistance (ISO 1431-1), and compression set (ISO 815). Our products undergo 3000-hour cyclic testing simulating 10+ years of service.

What innovations address installation stress at windshield corners?

Advanced corner molding uses precisely calculated bend radii that maintain seal cross-section integrity through compound curves. Our proprietary SD-001 design employs dual-durometer constructions that stiffen corner sections while maintaining flexibility in the curved zones.

Technical Parameters Evolution

Over the past decade, windshield rubber sealing strip performance standards have dramatically increased. Current ASTM D2000 classifications now require M4BG710 requirements, signifying enhanced material capabilities. Compression set resistance at 70 hours/100°C has decreased from 35% to under 25% in premium compounds, ensuring longer-term sealing integrity.

The automotive industry has implemented more demanding accelerated aging protocols. Where previous standards required 1000 hours of UV exposure, current BMW GS94001 specifications require 3000 hours. Similarly, low-temperature flexibility requirements have progressed from -30°C to -40°C test conditions, demonstrating increased performance expectations for modern sealing systems.

Industry References

"The development of next-generation sealing systems reflects the convergence of materials science and manufacturing technology. Modern EPDM formulations can now withstand tropical UV exposure exceeding 250 kJ/m² with minimal property degradation - a critical advancement for global vehicle platforms."

Rubber World Magazine Technical Review: Advances in Automotive Sealing Technology

"Compression set performance has emerged as the most predictive factor in long-term sealing effectiveness. Current research focuses on molecular architecture modifications that reduce stress relaxation in constrained applications by optimizing crosslink density distribution."

Journal of Applied Polymer Science: Viscoelastic Properties in Automotive Sealing Applications

"The automotive sealing industry is embracing sustainable materials that reduce lifecycle environmental impact without compromising performance. The most promising approaches include bio-sourced plasticizers, recycled rubber incorporation, and self-lubricating formulations that eliminate silicone-based installations sprays."

SAE Technical Paper 2021-01-1072: Sustainable Development in Vehicle Sealing Systems

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025