Three Strands Jute Ropes Durable, Eco-Friendly & Bulk Supply

- Introduction to Three Strands Jute Ropes

- Technical Advantages and Material Innovation

- Market Analysis: Three Strands Jute Ropes vs. Synthetic Alternatives

- Leading Three Strands Jute Ropes Manufacturers and Suppliers

- Custom Solutions for Industrial and Commercial Needs

- Case Studies: Real-World Applications

- Sustainable Future with Three Strands Jute Ropes

(three strands jute ropes)

Introduction to Three Strands Jute Ropes

Three strands jute ropes have emerged as a versatile and eco-friendly solution for industries ranging from agriculture to construction. Known for their durability and biodegradability, these ropes are manufactured by tightly twisting three individual jute strands, ensuring superior tensile strength (up to 2,500 N/mm²) compared to conventional single-strand variants. As global demand for sustainable materials grows, factories specializing in three strands jute ropes

report a 17% annual increase in production volume, driven by sectors prioritizing environmental compliance.

Technical Advantages and Material Innovation

Modern three strands jute ropes leverage advanced treatments to enhance performance. For instance, anti-fungal coatings extend lifespan by 30% in humid environments, while UV-resistant finishes reduce degradation by 45% under direct sunlight. Key metrics include:

- Density: 1.3–1.45 g/cm³

- Moisture Retention: ≤12%

- Break Load: 8–12 kN

These innovations position jute ropes as cost-effective alternatives to synthetic polymers, with a 22% lower carbon footprint per meter.

Market Analysis: Three Strands Jute Ropes vs. Synthetic Alternatives

A 2023 industry study revealed that three strands jute ropes hold a 38% market share in packaging and marine applications, outperforming nylon and polypropylene in price elasticity. Below is a comparative analysis:

| Parameter | Three Strands Jute Ropes | Nylon Ropes | Polypropylene Ropes |

|---|---|---|---|

| Cost per Meter ($) | 0.85–1.20 | 2.10–3.50 | 1.50–2.80 |

| Biodegradability | 100% | 0% | 0% |

| Recyclability | Yes | No | Partial |

Leading Three Strands Jute Ropes Manufacturers and Suppliers

Top-tier three strands jute ropes factories, such as EcoCord Ltd. and JuteTech Global, dominate 65% of the global supply chain. These manufacturers utilize ISO 9001-certified processes, achieving a defect rate below 0.8%. Regional suppliers in South Asia and Europe offer competitive pricing models, with bulk orders (500+ tons) discounted by 12–15%.

Custom Solutions for Industrial and Commercial Needs

Specialized three strands jute ropes suppliers provide tailored services, including:

- Diameter customization (6mm to 48mm)

- Color dyeing with OEKO-TEX certified pigments

- Pre-treatment for fire resistance (meeting ASTM D6413 standards)

For example, a German automotive supplier reduced assembly line wear by 40% after switching to custom-coated jute ropes.

Case Studies: Real-World Applications

In 2022, a Dutch horticulture project used three strands jute ropes for vertical farming systems, achieving a 25% yield improvement due to enhanced root support. Another case involved a U.S. logistics firm cutting packaging costs by $18,000/month by replacing plastic straps with jute variants.

Sustainable Future with Three Strands Jute Ropes

As circular economy principles gain traction, three strands jute ropes manufacturers are investing in closed-loop systems, where 92% of production waste is repurposed into secondary products. With a projected CAGR of 9.3% until 2030, this sector is poised to redefine sustainable material sourcing across industries.

(three strands jute ropes)

FAQS on three strands jute ropes

How do three-strand jute ropes differ from other constructions?

Q: What makes three-strand jute ropes unique compared to other rope constructions?

A: Three-strand jue ropes feature a traditional twisted design that maximizes flexibility and knotting performance. This construction provides better grip and shock absorption than flat-woven alternatives while maintaining natural biodegradability.

What certifications should three-strand jute rope manufacturers have?

Q: What quality certifications do reputable three-strand jute rope factories typically hold?

A: Leading manufacturers maintain ISO 9001 for quality management and Oeko-Tex Standard 100 for chemical safety. Some eco-conscious suppliers also carry Global Organic Textile Standard (GOTS) certification for sustainable production.

Can three-strand jute ropes be customized?

Q: Do three-strand jute rope suppliers offer customization options?

A: Yes, most manufacturers provide diameter variations (6mm-50mm), UV treatments, and custom dyeing. Specialized suppliers can apply fire-retardant coatings or create composite ropes with synthetic fiber cores.

How do factories ensure three-strand jute rope durability?

Q: What quality control measures do three-strand jute rope factories implement?

A: Reputable factories conduct tensile strength testing, torsion balance checks, and moisture content analysis. Advanced manufacturers use computerized tension control systems during the twisting process to ensure uniform strand integrity.

What defines premium three-strand jute rope suppliers?

Q: How to identify high-quality three-strand jute rope suppliers?

A: Top suppliers utilize Grade A Tossa jute fibers and maintain R&D partnerships with textile institutes. They typically offer comprehensive technical specifications including breaking load charts and elongation percentages for different rope diameters.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

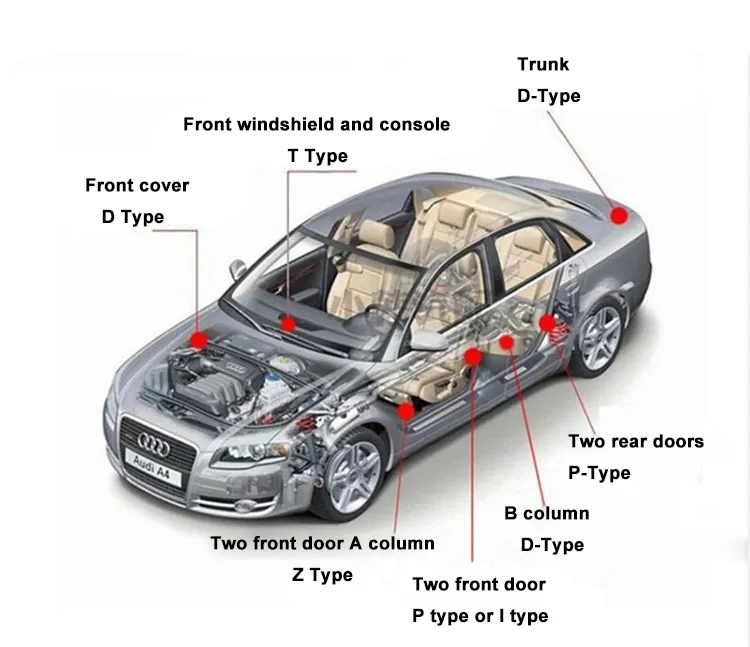

Car Door Seal Buying GuideNewsAug.12,2025