The Role of Slitting Machines in Lithium Battery Electrode Manufacturing

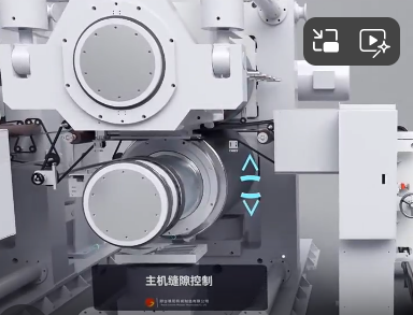

In the intricate process of lithium battery production, electrode manufacturing stands as a critical step that directly impacts battery performance, safety, and efficiency. Slitting machine, roll slitting machine, and coil slitting machine play a pivotal role here, transforming large rolls of electrode materials—coated with cathode or anode mixtures—into precisely sized strips ready for cell assembly. Xingtai Shuoding Trading Co., Ltd., established in September 2023, is part of a group with five factories producing lithium battery production line equipment, including advanced slitting solutions. With 18 employees, 9 of whom are experienced project managers, the company supports global importers and exporters, ensuring access to reliable machinery for electrode manufacturing. These slitting machines are the unsung heroes that bridge the gap between large-scale material production and the precise, small-scale components needed for high-quality lithium batteries.

How Slitting Machine Transforms Electrode Materials

- Precision Cutting for Uniform Strips: A slitting machine takes large rolls of electrode material—typically aluminum or copper foils coated with active materials—and cuts them into narrow strips of exact widths. This precision is crucial because even a 0.1mm deviation can lead to uneven cell stacking, affecting battery capacity and increasing the risk of short circuits. Modern machines use sharp, durable blades and advanced guiding systems to ensure each strip matches the exact specifications.

- Handling Delicate Substrates: Electrode materials are thin and fragile, especially after coating. A roll slitting machineis designed to handle these delicate substrates gently, minimizing tension to prevent stretching, tearing, or damage to the active material coating. This careful handling preserves the integrity of the electrode, ensuring consistent performance in the final battery.

- High-Speed Production Alignment: In high-volume manufacturing, coil slitting machineoperates at speeds that match the rest of the production line, avoiding bottlenecks. They can process hundreds of meters of material per minute, making them essential for meeting the demands of large-scale lithium battery production while maintaining precision.

Types of Slitting Machines for Electrode Manufacturing

- Roll Slitting Machine: Ideal for processing large rolls of electrode material, this type uses a continuous feed system to unwind the roll, slit it into strips, and rewind the strips onto smaller cores. It’s highly efficient for long production runs and is often used for mass-producing standard-sized electrode strips.

- Coil Slitting Machine: Designed for heavy-duty or thicker electrode substrates (though lithium battery electrodes are typically thin), this machine excels at handling rigid coils. It’s valued for its stability and accuracy, making it suitable for specialized electrode materials that require extra care during cutting.

- Laser Slitting Machines: While not a keyword, it’s worth noting that some advanced lines use laser technology alongside traditional slitting machine Lasers offer non-contact cutting, reducing material stress, but are often paired with mechanical slitting for cost-effectiveness in large-scale production.

Key Features of Slitting Machine for Electrode Quality

- Adjustable Cutting Parameters: Slitting machinesystems allow operators to adjust blade pressure, speed, and alignment based on the electrode material—whether it’s a thin cathode with a lithium cobalt oxide coating or a thicker anode with graphite. This flexibility ensures optimal cutting for each material type.

- Edge Trimming Capabilities: Along with slitting, these machines can trim the edges of electrode strips to remove irregularities. Smooth, burr-free edges prevent damage to separators in battery cells, reducing the risk of internal short circuits—a critical safety feature.

- Inline Inspection Integration: Modern roll slitting machinesetups include cameras and sensors that check strip width, edge quality, and coating integrity as they’re cut. This real-time inspection catches defects early, minimizing waste and ensuring only high-quality strips move to the next production stage.

Comparing Slitting Machine Performance in Electrode Production

|

Machine Type |

Speed Range |

Material Thickness Suitability |

Edge Quality |

Best For |

|

Roll Slitting Machine |

High (up to 300m/min) |

Thin to medium (5–50μm) |

Excellent (smooth) |

Mass production of standard strips |

|

Coil Slitting Machine |

Medium (50–200m/min) |

Thin to thick (5–100μm) |

Very Good (minimal burr) |

Specialized or rigid substrates |

This comparison shows how coil slitting machine and roll slitting machine each excel in different production scenarios, but both contribute to consistent electrode quality.

Slitting Machine FAQS

How Often Should Slitting Machine Blades Be Replaced?

Blades in a slitting machine typically last 8–12 hours of continuous use for electrode materials, depending on coating hardness. Regular inspection for dullness or chipping is key—dull blades can cause uneven edges, so replacement is crucial to maintain quality.

Can Roll Slitting Machine Handle Different Electrode Widths?

Yes, roll slitting machine is highly adjustable. Operators can reconfigure the blade setup to produce strips of varying widths (from a few millimeters to several centimeters) without extensive downtime, making them versatile for custom battery designs.

What Causes Uneven Strips in Coil Slitting Machine Operations?

Uneven strips in a coil slitting machine are often due to misaligned blades, inconsistent tension in the feed system, or worn-out guides. Regular calibration and maintenance prevent these issues, ensuring uniform strip dimensions.

How Does Slitting Machine Precision Affect Battery Performance?

Precision in a slitting machine directly impacts battery capacity and safety. Uniform strip widths ensure even current distribution in cells, maximizing energy output. Poor precision can lead to overlapping strips, short circuits, or reduced cycle life.

Where Can I Source Reliable Slitting Machine for Electrode Manufacturing?

Xingtai Shuoding Trading Co., Ltd., through its group’s factories, offers high-quality slitting machine solutions for lithium battery electrode production. Their equipment is designed to meet the strict precision and efficiency demands of electrode manufacturing. Visit their website to explore tailored slitting solutions for your production line.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025