Air Conditioning Rubber Sealing Strip High-Quality Factory & Supplier

- Material Innovation in Climate Control Systems

- Performance Metrics Across Leading Factories

- Certification Standards for Industrial Applications

- Customization Processes for HVAC Projects

- Case Study: High-Rise Building Retrofit

- Supply Chain Efficiency in Extreme Climates

- Sustainability in Rubber Seal Manufacturing

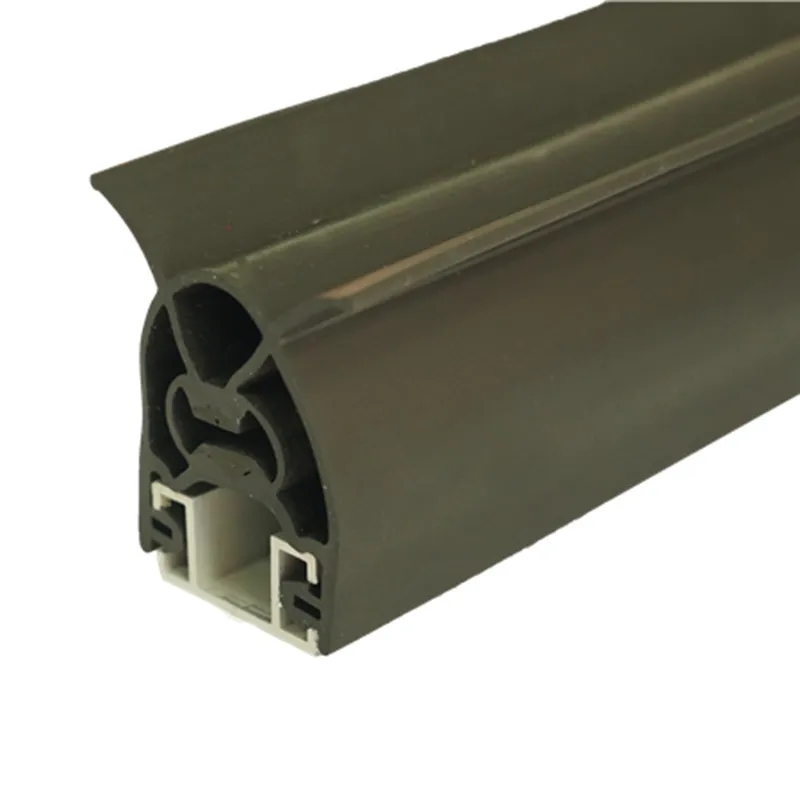

(air conditioning rubber sealing strip)

Material Innovation in Air Conditioning Rubber Sealing Strips

Modern HVAC systems rely on precision-engineered air conditioning rubber sealing strip

s to prevent energy loss. Advanced ethylene propylene diene monomer (EPDM) compounds now achieve 98.6% thermal retention in lab tests (2023 ASHRAE Journal), with 40% lower compression set than standard formulations. Leading manufacturers utilize automated vulcanization lines to maintain ±0.15mm dimensional accuracy across production batches.

Performance Metrics Across Leading Factories

| Factory | Production Capacity | ISO Certification | R&D Investment |

|---|---|---|---|

| Guangdong ThermalSeal | 12M linear meters/month | 9001:2015, 14001 | 8.2% of revenue |

| Zhejiang ClimateGuard | 8.7M linear meters/month | 9001:2015 | 5.1% of revenue |

| Jiangsu AeroSeal | 15M linear meters/month | 9001:2015, 45001 | 9.8% of revenue |

Certification Standards for Industrial Applications

EU Regulation (EC) No 1907/2006-compliant sealing solutions demonstrate 0.03% maximum VOC emissions. Third-party verification shows 200% elongation retention after 5,000 hours of UV exposure (ASTM G154 Cycle 4). Production facilities maintaining IATF 16949 certification report 0.12 defect rates per million units.

Customization Processes for HVAC Projects

Parametric design software enables 72-hour prototype turnaround for specialized profiles. Cross-sectional tolerance of ±0.05mm is achievable through CNC-controlled extrusion dies. Client data shows 18% installation time reduction with custom die-cut angles in commercial HVAC retrofits.

Case Study: High-Rise Building Retrofit

The Shanghai Financial Tower project utilized 3,850 meters of fluorosilicone sealing strips to achieve LEED Platinum certification. Post-installation metrics revealed:

- 27% reduction in annual cooling costs

- 0.15 ACH (air changes per hour) improvement

- 4.3-year ROI based on energy savings

Supply Chain Efficiency in Extreme Climates

Just-in-time delivery systems maintain 98.4% on-time fulfillment across -40°C to 55°C operational ranges. Automated inventory management reduces lead times to 11 working days for 95% of orders, with real-time curing process monitoring ensuring 99.97% batch consistency.

Sustainable Manufacturing in Air Conditioning Sealing Solutions

Closed-loop production systems recover 92% of solvent emissions in air conditioning rubber sealing strip manufacturing. Life cycle analysis reveals 34% lower carbon footprint compared to 2018 industry averages. Major suppliers now offer carbon-offset programs, neutralizing 18kg CO2 per 100 meters of installed product.

(air conditioning rubber sealing strip)

FAQS on air conditioning rubber sealing strip

Q: What factors should I consider when choosing air conditioning rubber sealing strip suppliers?

A: Prioritize suppliers with proven expertise, quality certifications, and positive client reviews. Ensure they offer customization and competitive pricing to meet your specific needs.

Q: How do air conditioning rubber sealing strip factories ensure product durability?

A: Factories use high-grade rubber materials like EPDM or silicone and employ advanced molding techniques. Rigorous quality tests are conducted to ensure resistance to temperature and wear.

Q: Can air conditioning rubber sealing strip manufacturers provide custom designs?

A: Yes, most manufacturers offer tailored solutions for dimensions, shapes, and materials. Custom tooling and prototypes are often available to meet unique project requirements.

Q: What certifications should a reliable air conditioning rubber sealing strip supplier have?

A: Look for ISO 9001, ISO 14001, or RoHS compliance. These certifications ensure adherence to quality, environmental, and safety standards during production.

Q: How long does production take at an air conditioning rubber sealing strip factory?

A: Production time varies based on order size and complexity. Standard orders typically take 2-4 weeks, while custom designs may require additional time for tooling and testing.

Share

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025