French Door Rubber Seal: Enhance Weatherproofing & Durability

Understanding the Critical Role of Advanced Sealing Solutions in Modern Architecture and Industry

In the rapidly evolving landscape of modern architecture and industrial applications, the integrity of sealing solutions is paramount. From maintaining energy efficiency in residential buildings to ensuring operational safety in complex industrial facilities, high-performance seals are non-negotiable. This article delves into the specifics of french door rubber seal technology, focusing on the sophisticated E type sealing strip, which exemplifies robust design and superior performance. We will explore its manufacturing precision, diverse applications, and the tangible benefits it offers across various sectors, ensuring that every installation meets the stringent demands of durability, resilience, and long-term cost-effectiveness.

The selection of an appropriate sealing solution is a critical decision impacting structural longevity and operational efficiency. Factors such as material composition, environmental resistance, and compression set characteristics play a vital role. For example, a high-quality french door rubber seal bottom is essential to prevent water ingress and air drafts, directly contributing to energy savings and interior comfort. As we proceed, we will highlight how expert engineering and stringent quality control protocols contribute to seals that not only meet but exceed industry standards, thereby providing unparalleled protection against environmental stressors and operational wear and tear.

The Advanced Manufacturing Process of High-Performance Rubber Seals

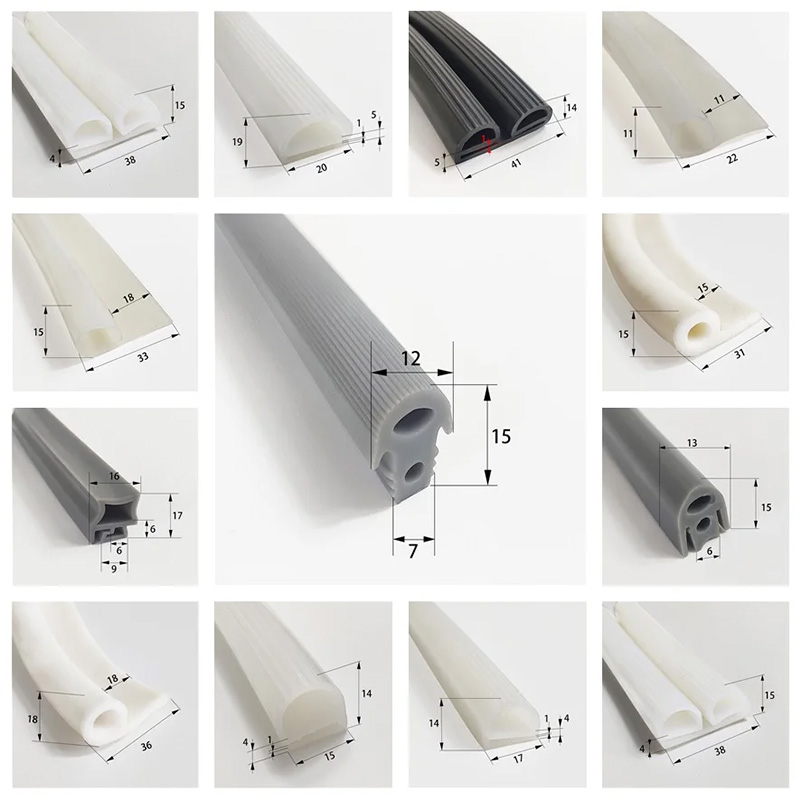

The production of a durable french door rubber seal, such as the E type sealing strip, involves a precise multi-stage manufacturing process designed to achieve optimal material properties and structural integrity. This begins with the careful selection of raw materials, primarily high-grade EPDM (Ethylene Propylene Diene Monomer) or Silicone rubber, chosen for their excellent resistance to UV radiation, ozone, extreme temperatures, and chemicals. The manufacturing journey typically follows a rigorous sequence:

- Material Compounding: Raw rubber polymers are blended with various additives, including curing agents (e.g., sulfur or peroxides), fillers (e.g., carbon black or silica for strength), plasticizers, and anti-degradants. This compounding process is crucial for achieving the desired Shore A hardness, tensile strength, and compression set resistance.

- Extrusion/Molding: For continuous profiles like the E type strip, the compounded rubber is fed into an extruder, where it is forced through a die to create the desired cross-sectional shape. For more complex geometries, compression molding or injection molding techniques are employed. This stage dictates the precise dimensions and form factor of the seal.

- Vulcanization (Curing): The extruded or molded rubber profile undergoes vulcanization, a critical process where heat and pressure are applied to chemically cross-link the polymer chains. This transforms the plastic, un-vulcanized rubber into an elastic, stable material with superior mechanical properties, improved temperature resistance, and reduced compression set.

- Cooling and Finishing: After vulcanization, the seals are cooled and may undergo trimming, cutting to length, or punching for specific applications. Automated optical inspection systems are often used to identify any dimensional inconsistencies or surface flaws.

- Quality Control & Testing: Throughout the process, stringent quality control measures are implemented. Products are routinely tested against industry standards such as ASTM D2000 for material classification, ISO 9001 for quality management, and specific performance tests like tensile strength, elongation, tear resistance, and accelerated aging tests to simulate long-term performance under various environmental conditions. This ensures the seals, including those used as a glazing rubber seal strip, meet or exceed specified performance criteria.

This meticulous manufacturing regimen ensures that each french door rubber seal exhibits exceptional durability and reliability, providing effective sealing against air, water, dust, and noise, while also offering energy conservation benefits by minimizing thermal transfer.

Technical Parameters and Performance Benchmarks

Selecting the correct french door rubber seal requires a thorough understanding of its technical specifications and how these parameters translate to real-world performance. The E type sealing strip, for instance, is engineered to meet rigorous demands across various industrial and architectural contexts. Key parameters include material composition, durometer hardness, temperature resistance, and compression set. These attributes collectively determine a seal's effectiveness in preventing air and water infiltration, reducing noise transmission, and contributing to overall energy efficiency.

| Parameter | Typical Range (E Type Sealing Strip) | Industry Standard Reference |

|---|---|---|

| Material | EPDM, Silicone, PVC (co-extruded) | ASTM D2000 M2BG710 A14 B13 C12 F17 |

| Hardness (Durometer Shore A) | 45-75 Shore A | ASTM D2240 |

| Operating Temperature Range | -40°C to +120°C (EPDM), -60°C to +200°C (Silicone) | ISO 11357, ASTM D412 |

| Tensile Strength | ≥ 5 MPa (EPDM), ≥ 4 MPa (Silicone) | ASTM D412 |

| Compression Set (22h @ 70°C) | Typically < 30% | ASTM D395, Method B |

| Ozone Resistance | Excellent, no cracking after 100h @ 50 pphm | ASTM D1149 |

| UV Resistance | Excellent, no degradation after prolonged exposure | ASTM G154 |

These specifications underscore the advanced engineering behind modern sealing solutions. For applications demanding extreme resilience, such as heavy duty rubber door seals for industrial equipment or hangar door rubber seals for large-scale facilities, these quantifiable metrics provide a basis for selection and performance prediction. Our E type sealing strips are consistently tested to ensure they meet these benchmarks, providing engineers and procurement specialists with reliable data for their projects.

Diverse Application Scenarios and Tailored Solutions

The versatility of high-quality french door rubber seal products extends across a broad spectrum of industries, providing essential protection and operational efficiency. In the architectural sector, these seals are indispensable for creating energy-efficient buildings, reducing heating and cooling costs, and enhancing occupant comfort by minimizing drafts and sound penetration. Beyond residential and commercial buildings, their robust design makes them ideal for specialized industrial and transport applications.

- Construction & Architecture: Integral for windows, doors (especially french door rubber seal bottom), curtain walls, and skylights, ensuring thermal and acoustic insulation.

- Automotive & Transport: Used in vehicle doors, trunks, and windows for weather-stripping and noise reduction. Examples include specialized horse trailer rubber door seal applications, where durability against constant vibration and outdoor exposure is critical.

- Industrial & Manufacturing: Essential for sealing enclosures, control panels, machinery access points, and large openings like those requiring hangar door rubber seals to protect sensitive equipment from dust, moisture, and temperature fluctuations.

- Marine: Employed in boat hatches, portholes, and cabin doors to withstand harsh saltwater environments and UV exposure.

- Energy Sector: Critical for sealing components in renewable energy infrastructure, such as wind turbine nacelles or solar panel mounting systems, requiring seals that can endure extreme weather and maintain integrity over decades.

Each application demands specific performance characteristics. For instance, a glazing rubber seal strip for structural glazing requires precise dimensional stability and long-term UV resistance, while heavy duty rubber door seals for industrial blast freezers need to maintain flexibility at extremely low temperatures without compromising sealing integrity. Our technical team works closely with clients to develop customized solutions, considering factors such as operating environment, chemical exposure, dynamic movement, and regulatory compliance to ensure the optimal sealing profile is specified for every unique challenge.

Technical Advantages and Competitive Edge

The E type sealing strip and similar advanced french door rubber seal products offer significant technical advantages that translate into superior long-term performance and cost savings. Unlike conventional sealing methods that may degrade rapidly, leading to frequent replacements and higher maintenance costs, our solutions are engineered for longevity and resilience. Key advantages include:

- Exceptional Durability: Formulated with high-grade EPDM or Silicone, these seals resist cracking, tearing, and abrasion, even under continuous use in harsh environments. This extends the service life significantly, reducing the total cost of ownership.

- Superior Environmental Resistance: Proven performance against UV radiation, ozone, extreme temperatures, and a wide range of chemicals ensures integrity in diverse climates and industrial settings. This resistance is crucial for applications such as a horse trailer rubber door seal where exposure to outdoor elements is constant.

- Optimized Compression Set: The ability of the seal to recover its original shape after prolonged compression is critical for maintaining an effective seal. Our products boast low compression set values, guaranteeing consistent sealing performance over time, preventing leakage and air infiltration.

- Enhanced Energy Efficiency: By creating airtight and watertight barriers, these seals significantly reduce thermal transfer, leading to substantial energy savings in heating and cooling, a key benefit for any building or temperature-controlled enclosure.

- Noise Reduction: The inherent material properties and precise fit of these seals contribute to excellent acoustic insulation, enhancing comfort in residential and commercial spaces, and reducing operational noise in industrial settings.

Our commitment to innovation is reflected in continuous material science research and advanced manufacturing techniques, setting our french door rubber seal products apart. We offer comprehensive technical support, from initial design consultation to post-installation performance monitoring, ensuring clients derive maximum value from their investment. This proactive approach to customer service and product development reinforces our position as a trusted partner in providing critical sealing solutions.

Commitment to Quality, Delivery, and Customer Support

At Xingtong Shuoding, our dedication to excellence in manufacturing french door rubber seal and related products is underpinned by a robust framework of quality assurance, efficient logistics, and comprehensive customer support. We are an ISO 9001 certified manufacturer, a testament to our commitment to consistently deliver products and services that meet international quality management standards. Our partnerships with leading engineering firms and construction companies over many years underscore our authoritative standing in the industry. For example, a recent project involving custom hangar door rubber seals for a major aerospace facility demonstrated our capability to deliver highly specialized solutions on an accelerated timeline, resulting in significant operational savings for the client.

Our standard lead time for the E type sealing strip and similar stock profiles is typically 2-3 weeks, with expedited options available for urgent projects. Custom orders may require 4-6 weeks depending on complexity. We offer a comprehensive 1-year warranty against manufacturing defects for all our rubber seals, providing our clients with peace of mind and assurance in the quality and durability of our products. Our technical support team is available from 9 AM to 5 PM (GMT+8) Monday through Friday to assist with product selection, installation guidance, and troubleshooting, ensuring seamless integration and optimal performance of your french door rubber seal solutions.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lifespan of an E type french door rubber seal?

- A1: Under normal operating conditions and proper installation, our E type seals, made from high-grade EPDM or Silicone, typically have a service life of 10-20 years. Factors such as extreme UV exposure, harsh chemicals, or continuous high compression can influence this, but the materials are designed for long-term resilience.

- Q2: Can these seals be customized for unique door profiles or applications?

- A2: Absolutely. While we offer a range of standard profiles, including those suitable for french door rubber seal bottom applications, our expertise lies in custom solutions. We can design and manufacture seals to specific dimensions, materials, colors, and performance characteristics to perfectly match your project requirements. This often involves tooling development and material formulation adjustments.

- Q3: What maintenance is required for the rubber seals?

- A3: Our high-quality french door rubber seal products require minimal maintenance. Regular cleaning with mild soap and water is recommended to remove dirt and debris. Avoid abrasive cleaners or petroleum-based solvents, which can degrade the rubber. Periodic inspection for signs of wear, cracking, or loss of elasticity is advisable, especially in high-traffic or harsh environments.

- Q4: How do your seals contribute to energy efficiency?

- A4: By creating an effective barrier against air infiltration and exfiltration, our seals drastically reduce heat loss in winter and heat gain in summer. This minimizes the load on HVAC systems, leading to significant reductions in energy consumption and lower utility bills. The superior thermal resistance of materials like EPDM and Silicone further enhances this benefit.

References

- ASTM International. (2023). Standards for Rubber, Carbon Black and Plastics.

- International Organization for Standardization. (2023). ISO 9001: Quality Management Systems – Requirements.

- Polymer Science and Engineering: The Properties of Engineering Polymers.

- Building Envelope Design Guide: Thermal Bridging and Air Leakage.

- Rubber Technology: Compounding and Testing for Performance.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025