High-Precision Pouch Cell Assembly Equipment & Manufacturing

Unlocking Global Battery Production: Top Manufacturers at the 137th Canton Fair

Discovering the future of pouch cell assembly equipment and pouch cell manufacturing innovations.

The 137th Canton Fair: A Gateway to Advanced Battery Production Lines

The Canton Fair, officially known as the China Import and Export Fair, stands as a pivotal event in the global trade calendar. For B2B decision-makers seeking the vanguard of industrial technology, its 137th session was an unparalleled opportunity. While traditionally a hub for diverse industries, this edition shone a particular spotlight on the burgeoning battery sector, showcasing cutting-edge advancements in battery production line technology.

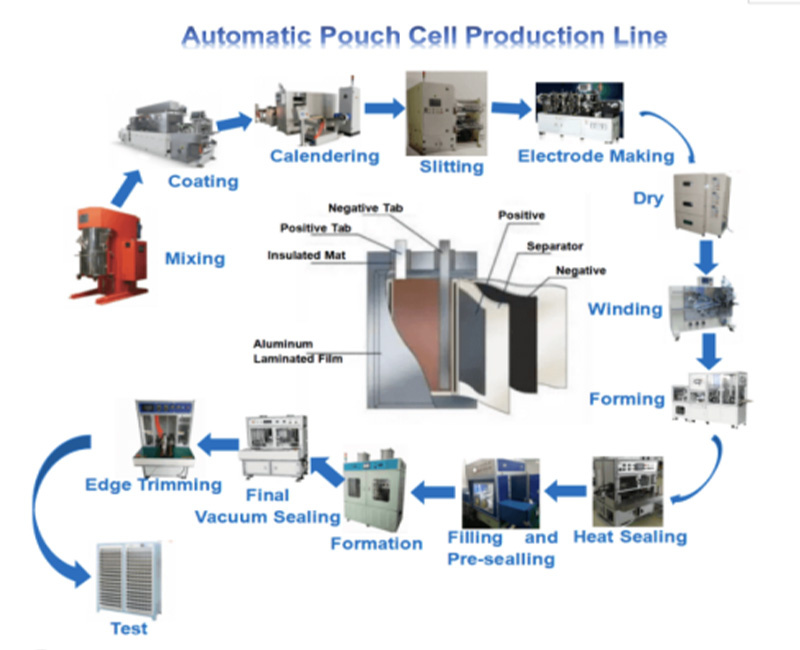

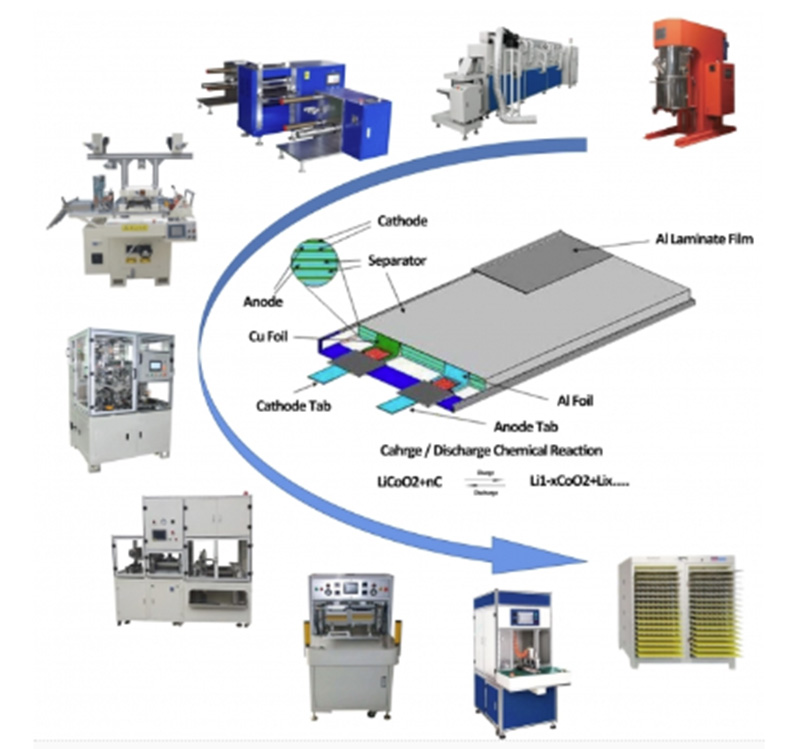

As the world accelerates its transition towards electric vehicles (EVs) and sophisticated energy storage systems (ESS), the demand for high-efficiency, reliable, and scalable battery manufacturing solutions has skyrocketed. The Canton Fair served as a crucial platform for Chinese innovators to demonstrate their prowess in this arena, connecting international buyers with the precision engineering required for modern pouch cell manufacturing. Exhibitors presented a diverse portfolio of equipment, from individual machines to complete turnkey lines, designed to meet the rigorous demands of the global market for pouch cell assembly equipment.

For manufacturers and investors looking to either establish new battery production facilities or upgrade existing ones, the fair provided invaluable insights and direct access to the innovators shaping the future of pouch lithium ion cells equipment production. It was a testament to China's leading role in supplying the foundational technology for the energy revolution.

Industry Trend Spotlight: The Ascent of Pouch Cell Manufacturing

The drive towards higher energy density, improved safety, and flexible form factors has propelled pouch cell manufacturing to the forefront of battery technology. These cells, characterized by their lightweight, flexible laminate casing, are increasingly favored for EVs, consumer electronics, and specialized ESS applications where space and weight optimization are critical. This surging demand necessitates equally advanced and reliable pouch cells equipment production capabilities.

The global battery manufacturing market is experiencing unprecedented growth. Projections indicate a compound annual growth rate (CAGR) exceeding 20% for lithium-ion batteries over the next decade, primarily fueled by the electrifying automotive industry and the massive build-out of renewable energy infrastructure. This expansion directly translates into an escalating demand for complete pouch cell battery assembly lines, capable of high-volume, precision manufacturing. Emerging markets, in particular, are rapidly investing in local battery production capabilities, making supply chain diversification and cost-efficiency in equipment sourcing paramount.

Key emerging focus areas in the pouch cell manufacturing process include:

- Automation and AI Integration: Enhancing precision, speed, and quality control, reducing human error, and optimizing throughput.

- Scalability and Modularity: Designing production lines that can easily scale up or adapt to varying capacity requirements and future battery chemistries.

- Sustainability: Focusing on energy-efficient manufacturing processes, waste reduction, and the integration of recycled materials.

- Digitalization of Production: Implementing Industry 4.0 concepts for real-time monitoring, predictive maintenance, and data-driven optimization of the entire pouch lithium ion cells equipment production workflow.

- Advanced Material Handling: Precision handling of delicate electrode materials and electrolytes to ensure cell integrity and performance.

These trends underscore the critical need for advanced pouch cell assembly equipment that not only meets current production demands but is also future-proofed against evolving technological landscapes.

Profiles of Leading Innovators in Battery Production Lines

Other Noteworthy Contributors to Battery Production Excellence

Beyond XINGTAI SHUODING, the 137th Canton Fair showcased a wide array of Chinese manufacturers contributing significantly to the global battery production line ecosystem. While specific names may vary from year to year, the fair consistently features companies specializing in different stages of the pouch cell manufacturing process:

- Precision Coating and Slitting Equipment Manufacturers: These companies offer highly accurate machines crucial for electrode preparation, ensuring uniform coating thickness and precise electrode dimensions for optimal cell performance.

- Automated Stacking and Assembly Solutions Providers: Innovators in high-speed, high-precision stacking machines that form the core of pouch cell assembly equipment, reducing bottlenecks and enhancing quality.

- Electrolyte Filling and Sealing Technology Experts: Critical for battery safety and longevity, these firms provide advanced vacuum filling and laser/heat sealing machines designed specifically for the delicate pouch cell format.

- Battery Formation and Testing System Developers: Offering sophisticated cycling equipment and comprehensive testing platforms essential for activating new cells and verifying their performance and safety parameters, vital for pouch lithium ion cells equipment production.

These companies collectively represent China's robust manufacturing capability and its strategic importance in equipping the world's battery factories with state-of-the-art pouch cells equipment production technology.

Market Outlook & Opportunities in Battery Production

The future of battery manufacturing is dynamic and filled with opportunities for strategic investment. Upcoming trends indicate a sustained demand for higher energy density, faster charging capabilities, and enhanced safety features in batteries, which will directly impact the design and capabilities of pouch cell manufacturing lines. Buyers are increasingly looking for partners who can offer not just equipment, but also integrated solutions that maximize efficiency and minimize downtime.

Key opportunities lie in:

- Advanced Automation and Robotics: Implementing collaborative robots and fully automated systems across the pouch cell manufacturing process to increase throughput and consistency.

- Smart Manufacturing & AI: Leveraging artificial intelligence for real-time process optimization, predictive maintenance, and defect detection, transforming traditional pouch cell battery assembly into intelligent, self-optimizing factories.

- Sustainability & Circular Economy: Developing energy-efficient production lines and processes that can integrate recycled materials and reduce environmental impact, aligning with global sustainability goals.

- Customization and Flexibility: Offering modular pouch cells equipment production lines that can be easily reconfigured to produce different cell sizes, chemistries (e.g., solid-state battery compatibility), and capacities, addressing diverse market needs.

- Global Expansion: As new gigafactories are announced worldwide, demand for robust and globally compliant pouch cell assembly equipment from reliable Chinese suppliers will continue to soar.

These areas represent significant growth avenues for both equipment manufacturers and the battery producers who invest in them, ensuring a competitive edge in a rapidly evolving market.

Buyer/Business Takeaways: Strategic Investment in Pouch Cell Technology

For B2B decision-makers, investing in cutting-edge pouch cell manufacturing equipment is not merely a purchase; it's a strategic imperative. The efficiency, reliability, and scalability of your production line directly correlate with your market competitiveness, product quality, and profitability. Here's why making smart investments in battery production line technology now makes profound business sense:

- Unlock Scale and Efficiency: Modern pouch cell assembly equipment is designed for high-throughput and minimal waste, crucial for meeting escalating global demand while optimizing operational costs.

- Ensure Product Quality and Safety: Precision engineering in every step of the pouch cell manufacturing process leads to superior cell performance, longer lifespans, and enhanced safety, critical for consumer trust and regulatory compliance.

- Gain a Competitive Edge: Early adoption of advanced pouch lithium ion cells equipment production allows for quicker market entry, faster innovation cycles, and the ability to adapt to new battery chemistries or form factors.

- Optimize Total Cost of Ownership (TCO): While initial investment in advanced machinery may seem high, the long-term benefits of reduced operational costs, lower maintenance, and higher output contribute to a significantly improved TCO.

Tips for adopting or partnering with Chinese manufacturers for pouch cell manufacturing lines:

- Conduct Thorough Due Diligence: Research manufacturer reputation, client testimonials, and visit existing operational lines if possible.

- Prioritize Customization and Scalability: Ensure the chosen pouch cells equipment production can be tailored to your specific production goals and scaled as your business grows.

- Verify After-Sales Support & Training: A robust support system, including spare parts availability, technical assistance, and operator training, is critical for seamless operation.

- Focus on Global Compliance: Confirm that the equipment meets international safety, environmental, and quality standards for your target markets.

Future-proofing your battery production strategy involves embracing modular designs, investing in R&D for next-generation pouch cell manufacturing techniques, and building strong, transparent relationships with equipment suppliers to ensure sustained innovation and reliability.

Conclusion: The Road Ahead for Battery Production

The 137th Canton Fair reinforced China's indispensable role in shaping the global battery production line market. It showcased a vibrant ecosystem of innovation, where manufacturers like XINGTAI SHUODING TRADING CO.,LTD are setting new benchmarks for efficiency, precision, and scalability in pouch cell manufacturing.

As the demand for advanced battery technologies continues its exponential rise, the partnerships forged and technologies unveiled at events like the Canton Fair will be instrumental in powering the next generation of electric mobility and sustainable energy solutions. For any enterprise serious about its future in battery production, engaging with these leading Chinese manufacturers is a critical step.

Ready to elevate your battery production capabilities?

Discover cutting-edge solutions for pouch cell manufacturing and complete turnkey lines.

Visit XINGTAI SHUODING TRADING CO.,LTD to learn moreShare

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025