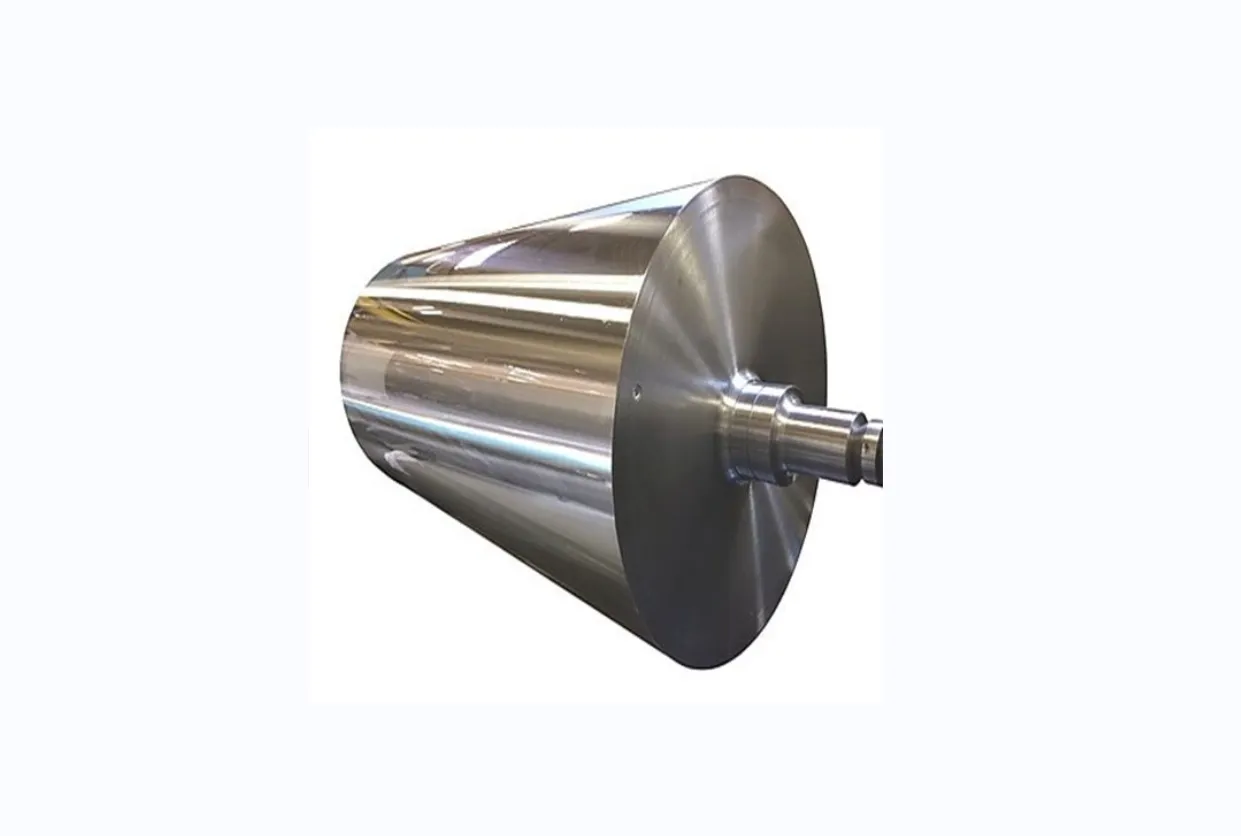

High Precision Roller Maintains Consistent Material Compression

In the intricate world of industrial manufacturing, achieving consistent material compression is the key to producing high-quality products. Xingtai Shuoding Trading Co., Ltd., a renowned roller manufacturer, offers top-of-the-line roller solutions designed to meet this critical requirement. Our high-precision rollers are engineered with meticulous attention to detail, ensuring that every compression process is carried out with utmost accuracy and consistency. Whether it's in lithium battery production or other material processing industries, our rollers play a pivotal role in enhancing production efficiency and product quality.

Xingtai Shuoding Trading Co., Ltd.’s Expertise as a Leading Roller Manufacturer

- Xingtai Shuoding Trading Co., Ltd. has firmly established itself as a leading roller manufacturerin the industry.

- With rich experience and a team of highly skilled professionals, we specialize in designing, developing, and producing high-precision rollers.

- Our commitment to quality is evident in every manufacturing aspect, from selecting premium materials to implementing strict quality control measures.

- As a trusted partner for many industries, we take pride in delivering rolling rollerproducts that exceed customer expectations in performance and durability.

The Technical Marvels Behind High Precision Rollers

Our high-precision rollers are a testament to advanced engineering and cutting-edge technology. Crafted from high-strength, wear-resistant materials, these rollers are designed to withstand the rigors of continuous operation while maintaining their precision. The surface of our rolling rollers undergoes a series of precise machining and finishing processes, ensuring a smooth and even contact with the materials. Advanced control systems integrated into our rollers enable real-time monitoring and adjustment of the compression force, guaranteeing consistent material compression throughout the production process.

The Role of Rolling Rollers in Ensuring Consistent Compression

- Rolling rollersfrom Xingtai Shuoding Trading Co., Ltd. play a crucial role in ensuring consistent material compression.

- These rollersare designed to apply uniform and controlled force across the entire width of the material being processed.

- By maintaining consistent pressure, our rolling rollersprevent uneven compression that can cause defects in the final product.

- Whether compressing battery electrodes or other industrial materials, ourrolling rollers deliver the reliability and precision needed for optimal results.

Yashizweho Roller Solutions for Diverse Industrial Needs

Understanding that different industries have unique requirements, we, as a roller manufacturer, offer customized roller solutions. Our team works closely with clients to understand their specific production needs and challenges. Based on this, we design and manufacture rollers that are tailored to their exact specifications. From adjusting the roller's size and shape to fine-tuning its performance parameters, we ensure that our customized solutions seamlessly integrate into our clients' production lines, enhancing their overall efficiency and productivity.

Rolling Roller FAQS

How do high precision rollers achieve consistent material compression?

Xingtai Shuoding Trading Co., Ltd.’s high precision rollers achieve consistent material compression through a combination of advanced design and technology. The use of high-quality materials provides the necessary strength and stability. Precision machining ensures a smooth and even surface, while integrated control systems continuously monitor and adjust the compression force. This combination allows our rollers to apply a consistent pressure throughout the process, resulting in uniform material compression.

Can your rolling rollers be used for different types of materials?

Yes, our rolling rollers are designed to be versatile and can be used for a wide range of materials. Whether it's soft and flexible materials like rubber sheets or hard and rigid materials such as metal plates, our rollers can handle them with ease. We can also customize the surface treatment of the rollers to suit the specific properties of different materials, ensuring optimal performance and consistent compression across various applications.

What maintenance is required for high precision rollers?

Maintenance for our high precision rollers is relatively straightforward. Regular cleaning is essential to remove any debris or residue that may accumulate on the roller surface, as this can affect the compression quality. Periodic inspection of the roller's surface for wear and tear is also recommended. Additionally, lubricating the moving parts of the roller system helps to ensure smooth operation. Our company provides detailed maintenance guidelines to help clients keep their rollers in optimal condition.

How long do your rollers typically last?

The lifespan of our rollers depends on various factors, including the frequency of use, the nature of the materials processed, and the maintenance practices. However, due to the high-quality materials and precision engineering, our rollers are built to last. With proper care and maintenance, our high-precision rollers can provide reliable performance over an extended period, offering a long-term and cost-effective solution for our clients.

Can you provide customized roller solutions quickly?

Yes, as an experienced roller manufacturer, we have the capabilities to provide customized roller solutions in a timely manner. Our streamlined design and manufacturing processes allow us to efficiently translate our clients' requirements into practical solutions. We maintain a well-stocked inventory of raw materials and components, which helps to reduce lead times. Our dedicated team also works closely with clients throughout the customization process to ensure that the final product meets their expectations promptly.

Sangira

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeAmakuruNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseAmakuruNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyAmakuruNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseAmakuruNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileAmakuruNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedAmakuruNov.10,2025