Lithium Cell Machinery - Automated, Precise, Scalable Lines

What I Learned Touring an Automated Lithium Battery PACK Line

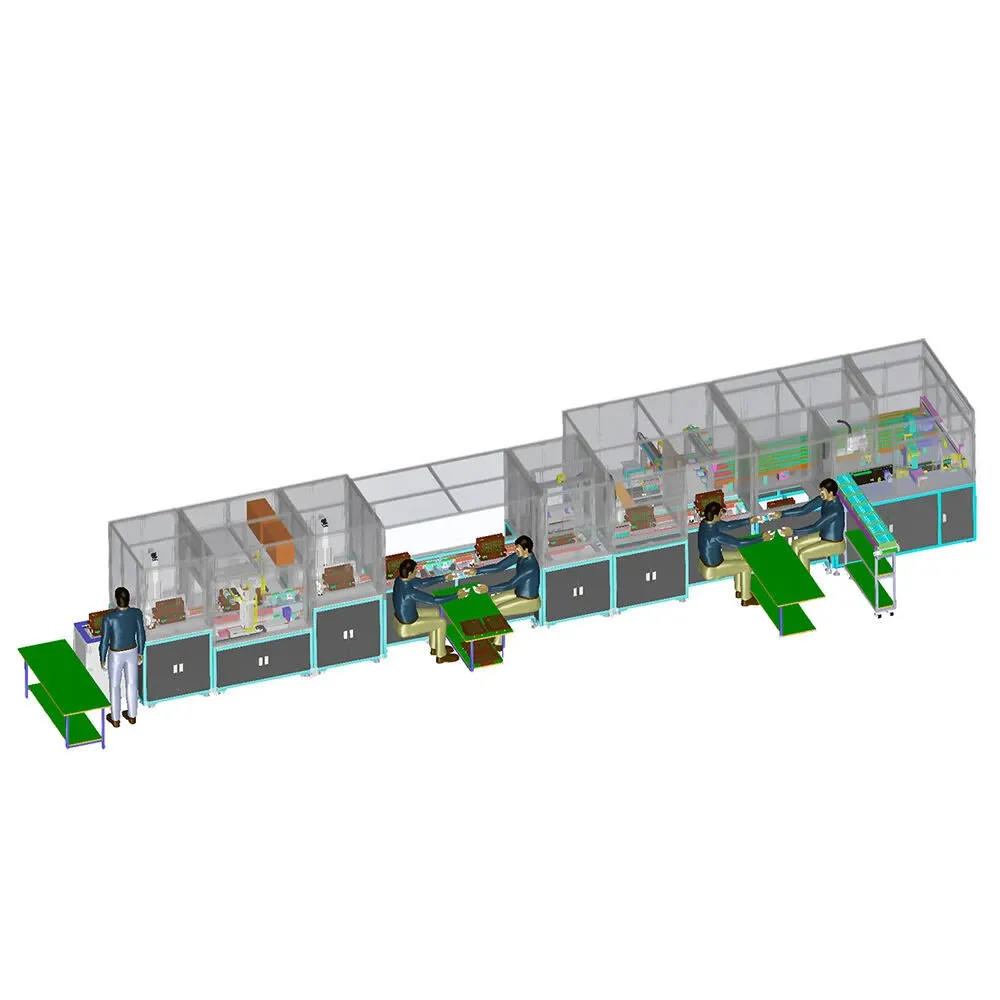

If you’re scoping serious factory upgrades, you’ll eventually trip over Lithium Cell Machinery. I spent a day on the floor with the Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System—yes, a mouthful—at a facility that, to be honest, smelled faintly of flux and ambition. The pitch is clear: Industry 4.0 meets high-precision automation for battery-pack manufacturing. Actually, it’s the traceability and repeatability that win engineers over, not just the shiny robots.

Industry snapshot

Demand for EVs and stationary storage has pushed pack assembly toward higher throughput and fewer touchpoints. We’re seeing a shift to flexible lines that handle prismatic, cylindrical, and pouch formats without massive retooling. Surprisingly, many buyers now ask first about MES hooks, vision analytics, and closed-loop control—then talk takt time. That’s where this system leans in: smart manufacturing with full-device traceability and automated quality gates. In short, Lithium Cell Machinery is no longer just mechatronics; it’s data infrastructure.

Process flow (what actually happens)

- Incoming QC: cell OCV/IR sorting, barcoding, ESD-controlled staging (per IEC 61340 best practices).

- Module build: cell loading, alignment, adhesive dispensing, compression, nickel/busbar placement.

- Interconnects: laser welding (fiber, typically), weld pull testing, camera-based seam inspection.

- Pack integration: BMS installation, harness routing, thermal interface material (TIM) placement.

- End-of-line: hi-pot, insulation resistance, charge/discharge, leak check (where applicable), UN 38.3 pre-compliance profiling.

- Data: MES traceability, recipe control, SPC dashboards, and auto-rework routing.

Materials: cells (LFP/NMC), nickel tabs, Cu/Al busbars, TIM pads, structural adhesives, BMS, enclosures. Methods: robotic dispensing, laser welding, torque-controlled fastening, AOI. Testing standards referenced: UN 38.3, IEC 62133, UL 2580. Service life targets (customer dependent): ≈2,000–4,000 cycles at 80% SOH; real-world use may vary across duty cycles and thermal management. Industries: EV/HEV, e-mobility, AGV/AMR, telecom backup, and grid-tied ESS.

Product specifications (typical configuration)

| Parameter | Spec (≈, real-world may vary) |

|---|---|

| Supported cells | Prismatic, cylindrical (incl. 18650/21700), pouch |

| Takt time | ≈6–15 s/module depending on welds and AOI depth |

| Welding | Fiber laser, up to ≈2 kW; seam repeatability ±0.05 mm |

| Vision accuracy | ±0.03–0.05 mm AOI alignment |

| Yield (EOL) | ≥98% on mature recipes |

| OEE design target | ≥85% |

| ESD & Safety | ESD protected; safety circuits to PL d / CAT 3 where applicable |

| Compliance | UN 38.3, IEC 62133, UL 2580 (pack-level testing) |

| MES/SCADA | OPC UA/REST; recipe & traceability built-in |

Vendor comparison (indicative)

| Vendor | Takt time | Flexibility | Certs | After-sales | Notes |

|---|---|---|---|---|---|

| XT SHUODING (China) | ≈6–15 s | High (multi-format) | ISO 9001 / IATF 16949 (plant-level) | Remote + on-site; spares stocked | Strong MES integration |

| Vendor A (EU) | ≈8–20 s | Medium-High | ISO/IATF, CE focus | Strong regional presence | Premium pricing |

| Vendor B (US) | ≈7–18 s | High | UL/CSA emphasis | Onshore service | Fast NPI support |

Why teams pick it

- Closed-loop vision + laser welding consistency; fewer reworks.

- Quick changeover across cell formats; future-proofing for new chemistries.

- Full traceability: lot-to-pack genealogy, SPC, and recipe locks.

- Factory fit: modular skids, shorter commissioning time.

And yes, Lithium Cell Machinery sometimes gets judged on maintenance. Many customers say the spares availability is decent and remote diagnostics save trips.

Customization and deployment

Options include adhesive types, laser heads, torque tools, AOI depth, pack sizes, and MES/SCADA connectors (OPC UA/REST). Site of origin: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China. For regulated markets, Lithium Cell Machinery projects typically map to UN 38.3 transport tests, IEC 62133 safety, and UL 2580 for EV packs.

Mini case notes

- ESS integrator (MENA): boosted yield from ≈96.5% to 98.7% after AOI+SPC tuning; line capacity +22%.

- E-mobility OEM (EU): changeover between 21700 and prismatic cut from 8 hours to ≈2.7 hours; fewer weld defects after recipe locking.

Test data and certifications

Factory Acceptance Tests (FAT) often include GR&R on alignment (≤10%), weld nugget pull tests, and hi-pot up to around 3 kV depending on pack design. Typical quality system alignments: ISO 9001 and IATF 16949 at the plant level. Final pack certification follows the customer’s intended market and standards stack.

References:

- IEC 62133-2:2017 — Safety requirements for portable sealed secondary lithium cells and batteries. https://webstore.iec.ch/publication/28776

- UN Manual of Tests and Criteria, Part III, Sub-section 38.3 (UN 38.3). https://unece.org/transportdangerous-goods/un-manual-tests-and-criteria

- UL 2580 — Batteries for Use In Electric Vehicles. https://standardscatalog.ul.com/standards/en/standard_2580

- ISO 9001:2015 Quality management systems. https://www.iso.org/iso-9001-quality-management.html

- IATF 16949:2016 Automotive QMS. https://www.iatfglobaloversight.org/iatf-16949/

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025