Round Metal File: Hardened Steel—Which Size Fits?

The Insider’s Guide to the round metal file: specs, trends, and real shop data

If there’s one quiet hero in metalworking, it’s the round metal file. I’ve watched machinists reach for it without thinking—when nothing else quite fits the radius, this does. It’s the tool for truing holes, enlarging circular openings, deburring inside pipes, shaping semicircular grooves, and yes, sculptors swear by the narrow point for fine control. Simple, but not simplistic.

What’s new in the category

Trends are subtle but real: higher hardness stability for longer life, cleaner tooth geometry for stainless and nickel alloys, better anti-rust coatings, and a steady rise in private label customization. Interestingly, additive manufacturing shops now keep a round metal file handy for post-print blending. Many customers say ergonomics matter more than they expected—less chatter, faster bite, fewer slips.

Technical specifications (real-world focused)

| Item | Spec (≈, ranges reflect practical production) |

|---|---|

| Product | Round file products (tang type) |

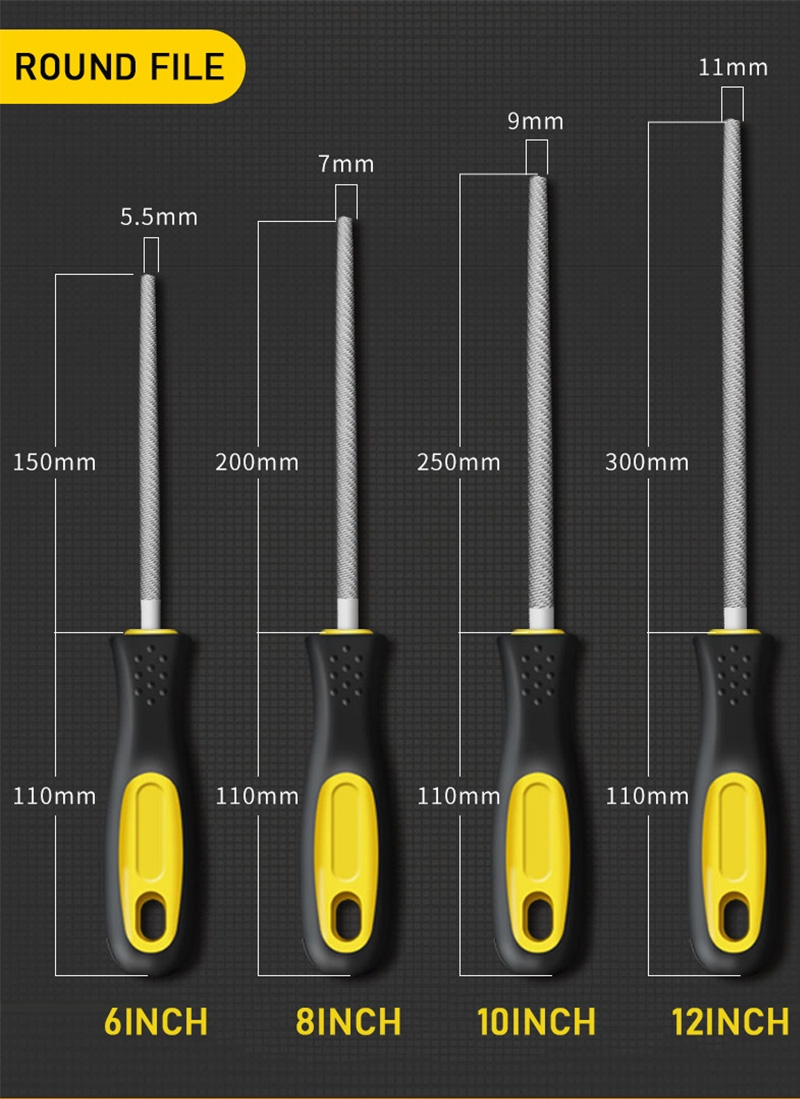

| Length options | 100 / 150 / 200 / 250 / 300 mm |

| Diameter range | ≈ 3–16 mm at the working end |

| Cut grades | Bastard, Second, Smooth; single-cut profile |

| Steel | High-carbon T12 / 65Mn; optional Cr-V |

| Hardness | Body 62–66 HRC; tang 45–50 HRC (ASTM E18) |

| Finish | Black oxide or clear anti-rust lacquer |

| Standards | ISO 234-1; JIS B 4703 compliant |

Process and quality flow (how it’s actually made)

Material selection → hot rolling and tapering → normalizing/anneal → blank grinding → machine tooth-cutting → hardening and tempering → straightening → surface coating → final inspection (hardness, geometry, tooth integrity) → packing.

Test snapshots: hardness 64±2 HRC; wear loss after 10,000 strokes on HB120 steel ≤0.12 mm tooth height loss (lab average); salt spray 24 h no red rust on coated zones (ASTM B117). Dimensional tolerance: diameter ±0.2 mm; length ±1 mm. Service life: around 3–12 months depending on alloy and pressure—shop habits matter, a lot.

Where it shines

- Metal fabrication: enlarging and truing circular holes

- Plumbing/HVAC: inside-pipe deburring (steel, copper, PVC)

- Toolroom: keyways and semicircular groove finishing

- Jewelry/sculpture: controlled radii with the narrow point

- Additive manufacturing: post-print blend without gouging

Vendor comparison (indicative, based on public data and buyer feedback)

| Vendor | Origin | Steel | HRC | MOQ | Customization | Certs | Lead time |

|---|---|---|---|---|---|---|---|

| XT ShuoDing Round file products | Xingtai, Hebei, China | T12 / 65Mn | 62–66 | ≈500–1000 pcs | Logo, cut, size, handle | ISO 9001 | 15–25 days |

| Bahco | EU | C75/Cr-V | 60–65 | 50–200 | Limited | ISO 9001 | 5–10 days |

| PFERD | Germany | C75/Cr-V | 60–65 | 20–100 | Limited | ISO 9001 | 7–14 days |

| Nicholson | US/BR/MX | C1095 | 60–65 | 50–200 | Limited | ISO 9001 | 7–14 days |

Customization and practical tips

From my notes: buyers increasingly request private labels and tuned hardness for stainless. ShuoDing (origin: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei, China) offers logo etch, bespoke diameters, alternate coatings, and matched handle sets. To be honest, a properly stored round metal file (dry, oiled, tooth guard on) easily doubles its life.

Mini case study

A plumbing OEM in Eastern Europe switched to this round metal file for 32 mm copper pipe ends. Results after 8 weeks: rework down 22%, average changeover extended from 2 shifts to 3, and fewer scratches on soft copper (operators reported “cleaner bite, less clogging”). Not earth-shattering, but on volume that’s serious money.

Certifications and compliance

Manufactured to ISO 9001 quality systems; product geometry aligned with ISO 234-1 and JIS B 4703. Hardness tested per ASTM E18; corrosion checks per ASTM B117. Materials are typically RoHS-friendly (ask for batch report—real-world lots may vary).

Citations

- ISO 234-1: Hand files and rasps — Specifications.

- JIS B 4703: Files — Dimensions and quality.

- ASTM E18: Standard Test Methods for Rockwell Hardness of Metallic Materials.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASM Handbook, Vol. 4: Heat Treating (reference for hardening/tempering practice).

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025